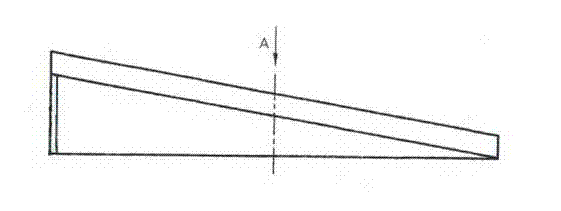

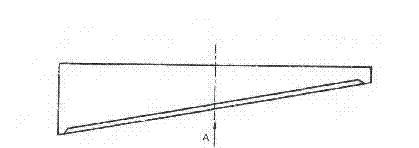

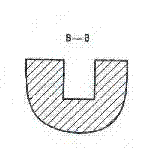

Method for producing upper and lower blades of edge cutting machine

A production method and edge machine technology, which are applied to the production field of upper and lower blades of edge diggers, can solve the problems of low machining accuracy, low production efficiency, inconvenience in automation, etc., and achieve the effects of improving efficiency, reducing production costs, and improving working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] In the material selection of the present invention, scrap steel material is used as the base material, the material content is adjusted to C0.7%, Cr7%, Mo1.5%, and the W content is increased by 0.2-0.3%, in order to reasonably promote the formation of carbides and refine them to the greatest extent Organization, enhance the toughness of the material, improve the service life of the product, so that the composition is controlled at (mass percent): C:0.6-0.7, Cr:6.2-7.8, Mo:1.2-1.8, W:0.2-0.3, V:1.7-2.2 , Si: 0.5-1.8, Mn: ≤0.4, P ≤ 0.03, S ≤ 0.03.

[0050] Melt the scrap steel, supply oxygen to the electric furnace melting pool, oxidize the carbon in the furnace charge to the specified range; remove S, P, O in the raw material and gas such as H, N and non-metallic inclusions in the steel by slagging to ensure the quality of the steel Quality; adjust the alloy composition to meet the requirements of the tapping temperature. LF+VD refining process equipment is adopted. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com