Access cover assembly of automobile fuse box

A technology of fuse box and access cover, applied in vehicle parts, emergency protection devices, electrical components, etc., can solve the problems of complex installation structure, increased cost, single function, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be further described in conjunction with accompanying drawing and embodiment:

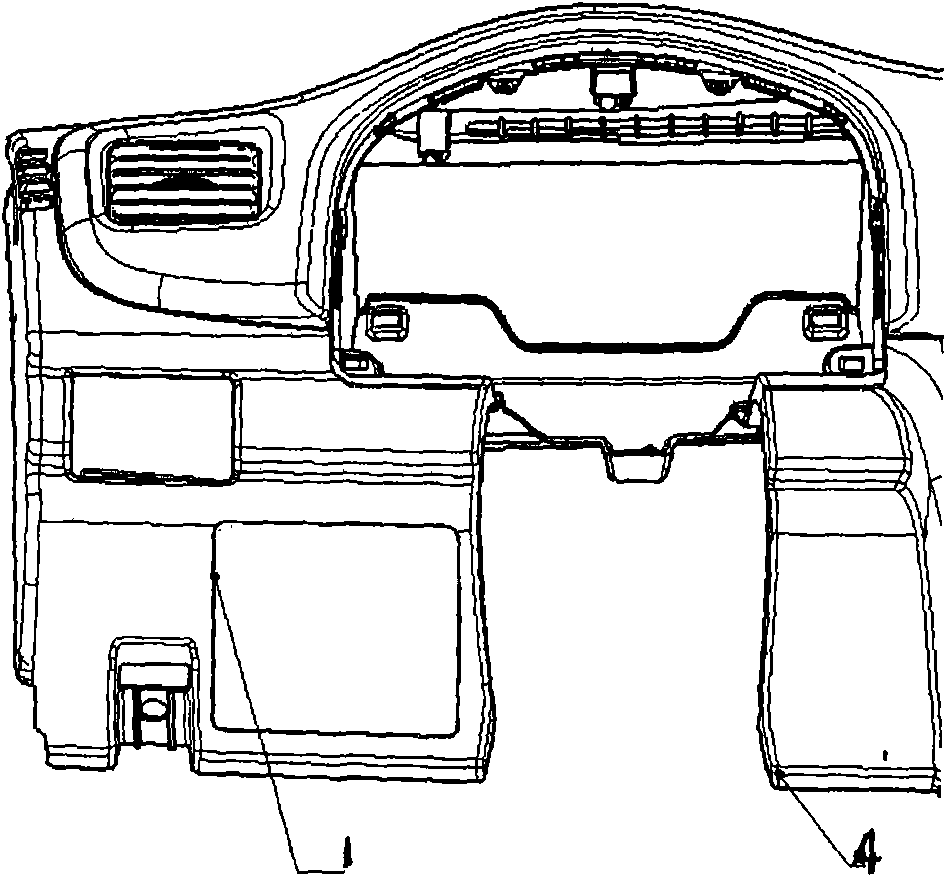

[0022] see figure 1 1. The automobile fuse box inspection cover assembly is installed in the opening 1 of the instrument panel assembly 4. for easy access to the fuse box.

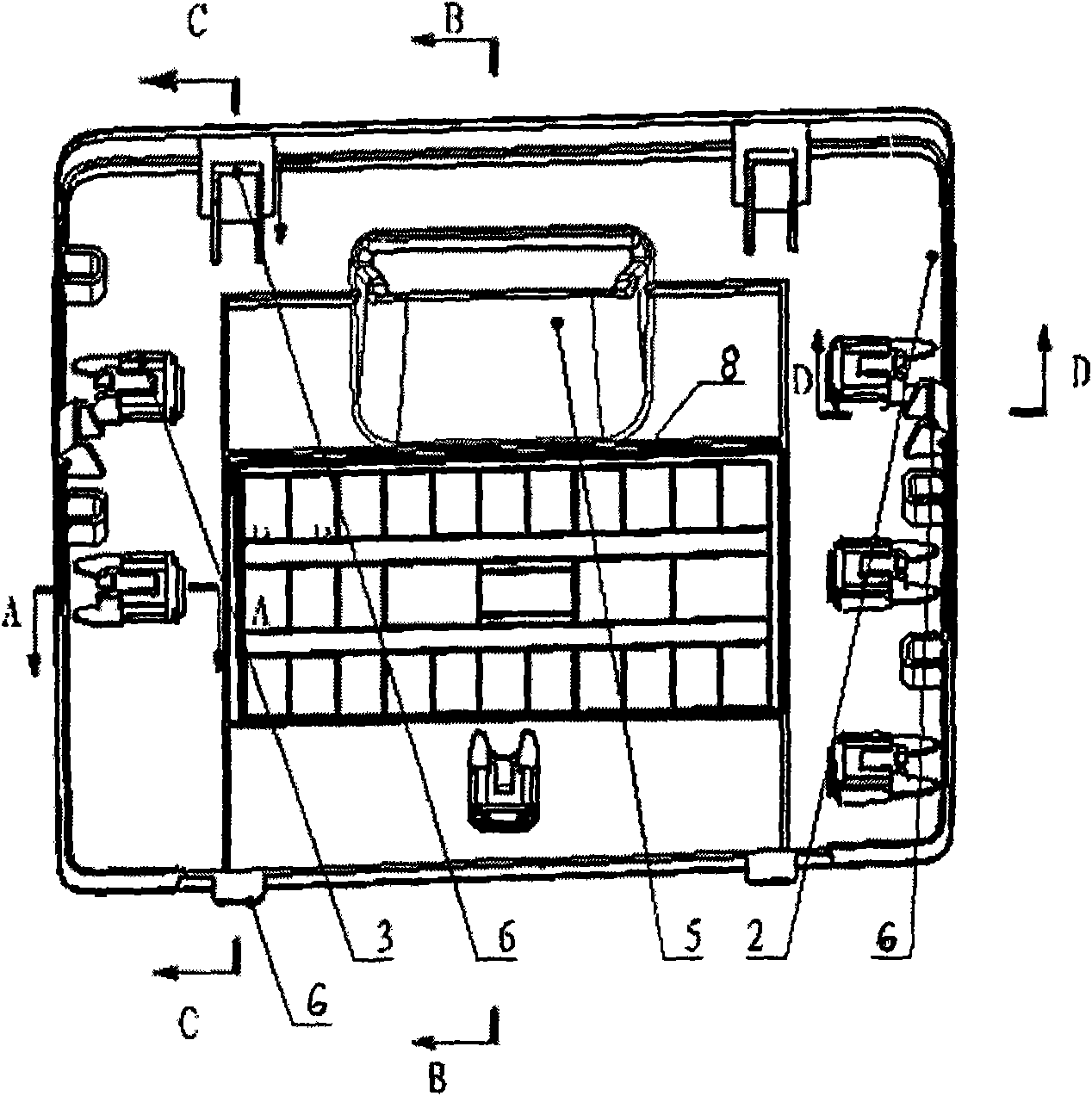

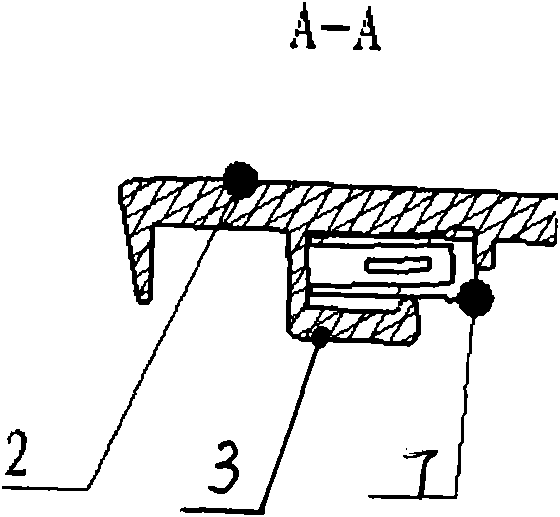

[0023] see figure 2 , the access cover assembly is an integral injection molded part, the main body of which is the cover body 2, and all structures are integrated on the cover body 2. On the inner surface of the cover body 2, there are clamping structures 6 distributed on the upper, lower, left, and right edges, which are used to clamp the cover body 2 to the instrument panel assembly 4, which is convenient for assembly. For the specific clamping forms of each part, refer to Figure 4 , Figure 5 and Figure 6 .

[0024] The middle position of the inner surface of the cover body 2 is embossed with a partition cell 8 indicating the current of the fuse. There is a handle hole 5 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com