Automobile fuse full-automatic assembling machine

A fuse and assembly machine technology, applied in the manufacture of fuses, etc., can solve problems such as difficult quality control and long time consumption, and achieve the effects of improving stability, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

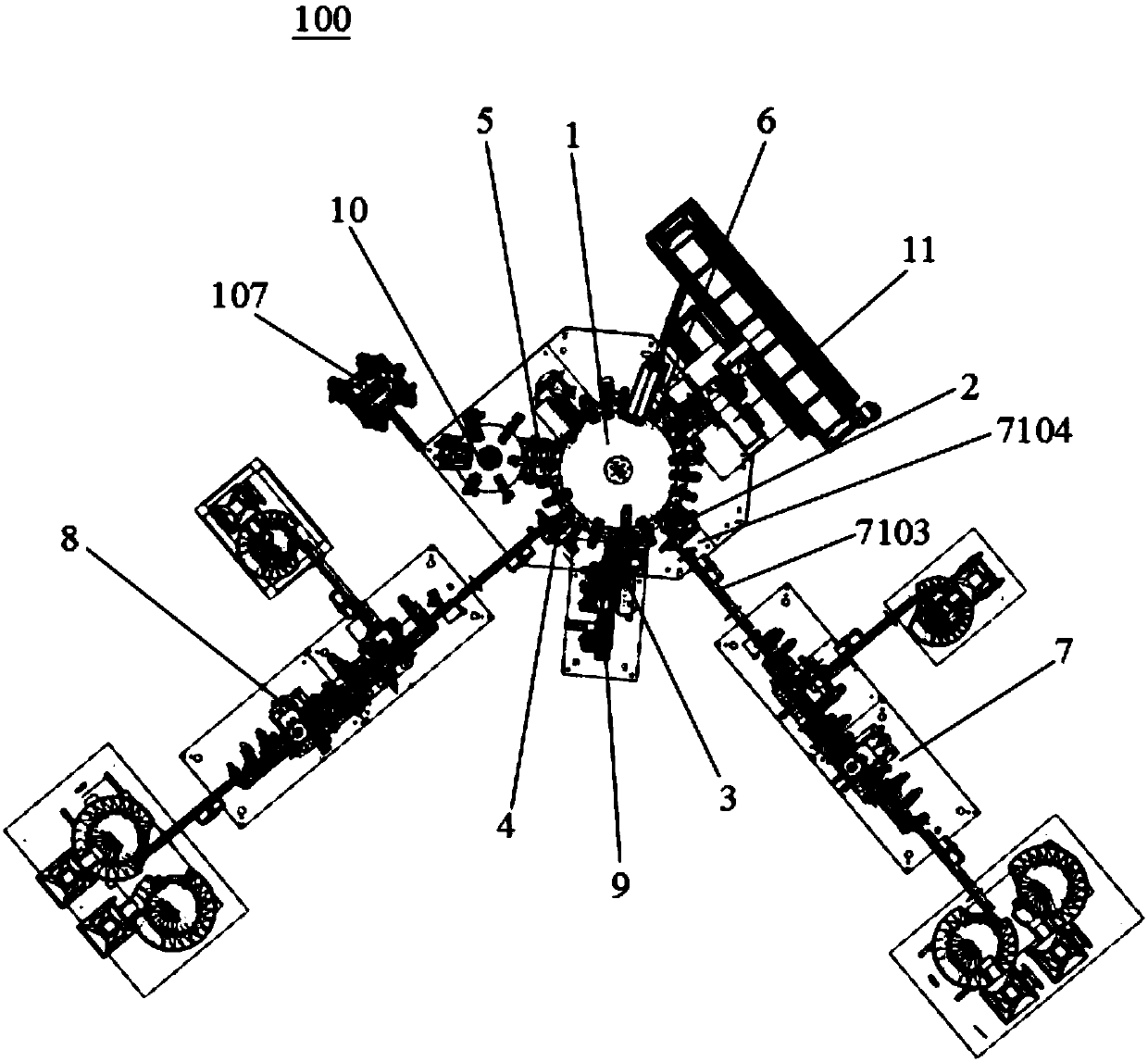

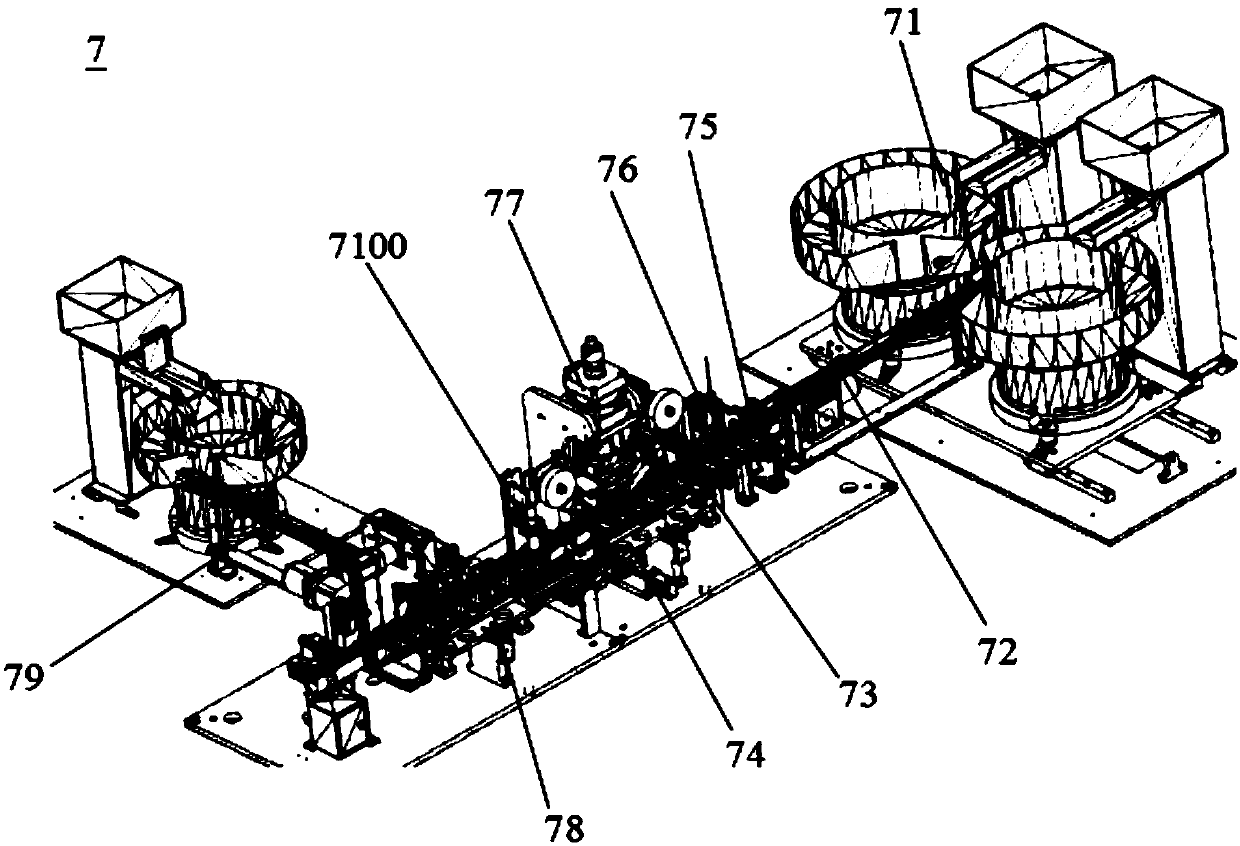

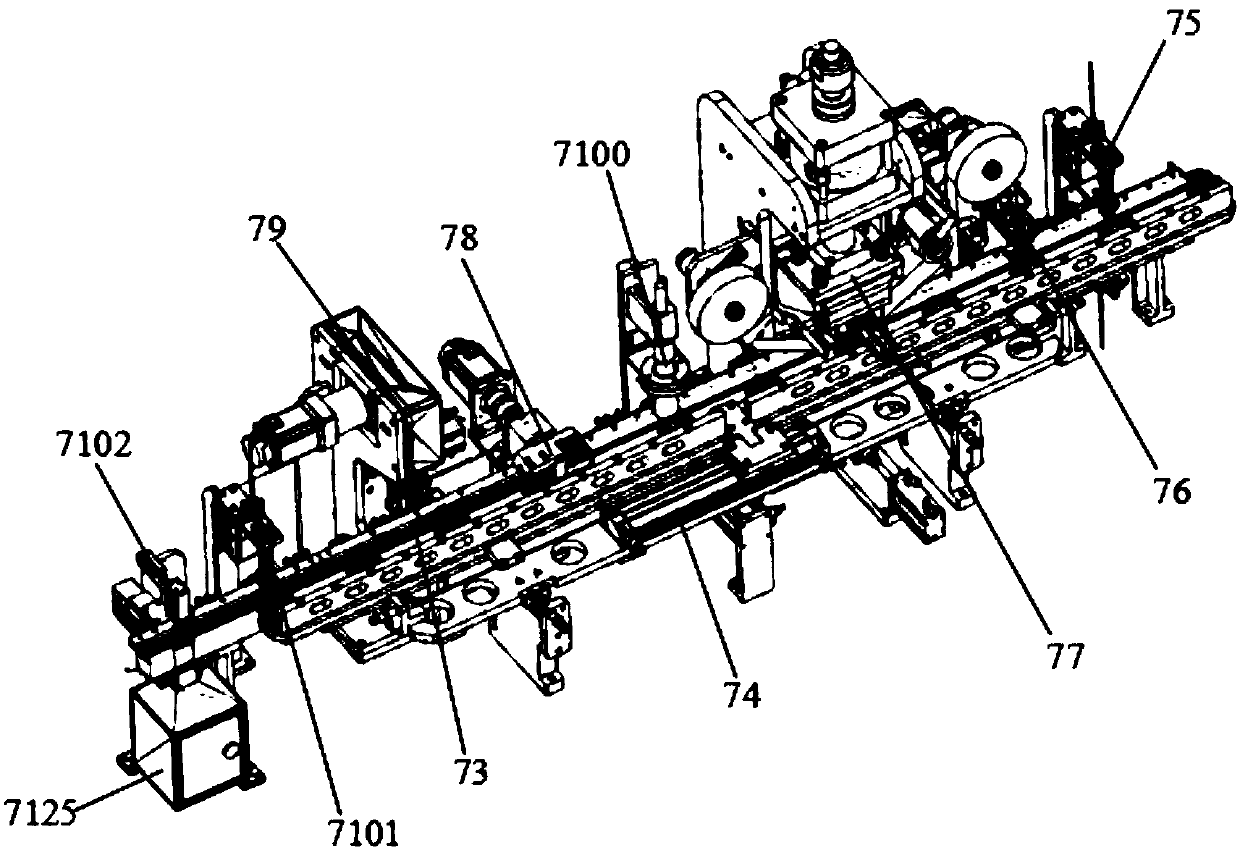

[0047] Please refer to figure 1 , the present embodiment is an automobile fuse automatic assembly machine 100, which includes a rotating first rotating disk 1, a lower casing input station 2 arranged around the first rotating disk 1, a fuse loading station 3, an upper casing Loading station 4, rivet pressing station 5, product output station 6 and the detection unit arranged between each station, the lower casing input station 2 is docked with the lower casing assembly detection line 7, the upper The upper casing assembly detection line 8 is installed at the 4th docking station of the shell loading station, the fuse cutting detection device 9 is installed at the 3rd docking station of the fuse loading station, and the riveting assembly inspection is provided at the 5th docking station of the rivet pressing station The line 10 and the product output station 6 are connected with a marking and blanking line 11 .

[0048] A plurality of first carrying jigs 1101 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com