Automatic cleaning equipment for printed circuit board

A printed circuit board, automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems affecting the quality of printed circuit boards, low cleaning efficiency, etc., and achieve cleaning effect Good, the effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

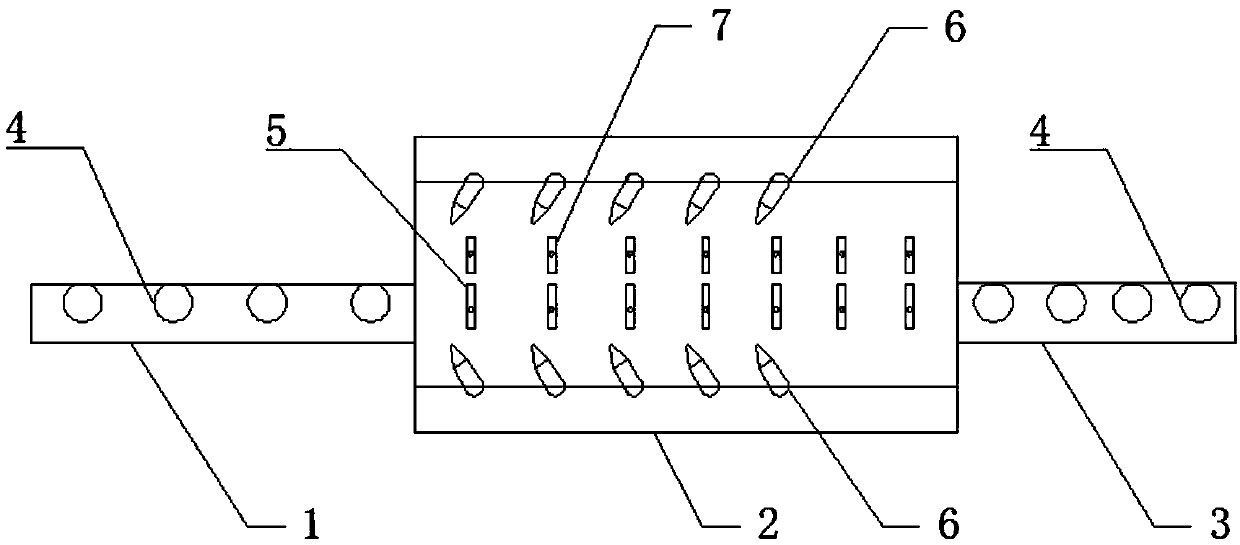

[0025] According to an embodiment of the present invention, preferably, the spraying devices 6 are divided into two groups, and the two groups of spraying devices 6 are symmetrically arranged on both sides of the cleaning box conveying device 5 along the conveying direction of the printed circuit board, The front and back sides of the printed circuit board can be cleaned at the same time, and the cleaning efficiency is high.

[0026] According to one embodiment of the present invention, preferably, the spraying device 6 is arranged close to the feed inlet, and the arrangement length of each group of spraying devices 6 is less than 2 / 3 of the length of the cleaning tank 2, and the remaining The cleaning box 2 of the length is arranged with the spraying equipment 6, so that after the printed circuit board is cleaned, part of the water can be drained and then transported out from the outlet of the cleaning box 2 to enter the next manufacturing link.

[0027] According to an embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com