High elastic recovery fabric, fabric production process and fabric application

A technology of elastic fabrics and production technology, which is applied in the field of clothing fabrics and fabrics, can solve the problems of poor comfort and low clothing applicability, and achieve the effect of easy to wear, not easy to aging and cracking, and reliable and stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058]The base gel flu fluid includes: 100 parts of hydroxy silane; 3 parts of vinyl triethoxysilane; 35 parts of alkane solvent; 3 servant black; 0.2 parts of titanate chelate; 5 parts silica thickening Agent.

[0059]The hydroxyl group content of the hydroxyrosilicone oil is 1%, and the viscosity at ambient temperature is 25 ° C to 20 mp · second.

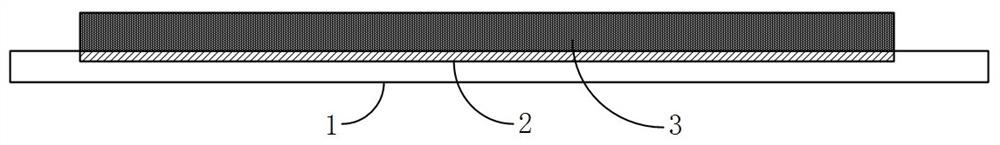

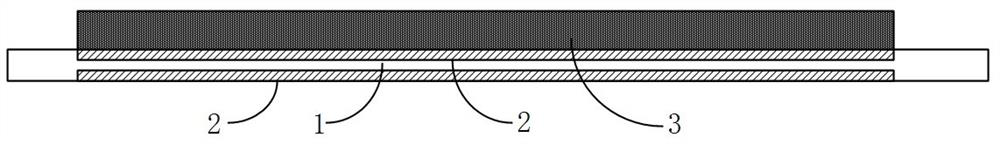

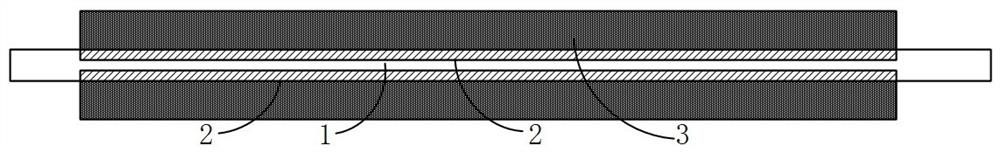

[0060]The lateral direction of the elastic fabric is 294%, and the recovery rate is 98.4%. The elastic glue penetration depth is 1 / 3 of the elastic fabric thickness, and the thickness of the fluff fiber is twice the thickness of the elastic fabric.

[0061]The lateral direction opening degree of the elastomer 2 region of the resilient fabric 1 is 289%, and the recovery rate is 98.3%.

Embodiment 2

[0063]The base gel flu fluid includes: 100 parts of hydroxy silane; 2 parts of vinyl triethoxysilane; 40 parts of alkane solvent; 4 parts carbon black; 0.5 parts of titanate chelate; 4 parts silica thickening Agent.

[0064]The hydroxysilicide content of the hydroxyrosilicone oil is 1.5%, and the viscosity of 15 ° C at ambient temperature is 15 mp.

[0065]The lateral direction of the elastic fabric is 294%, and the recovery rate is 98.4%. The elastic glue penetration depth is 1 / 3 elastic fabric thickness. The thickness of the fluff fiber is twice the thickness of the elastic fabric.

[0066]The elastic adhesive 2 region of the elastic fabric 1 is 291%, and the recovery rate is 98.4%.

Embodiment 3

[0068]The base gel fluid includes: 100 parts of hydroxy silage; 4 parts of vinyl triethoxysilane; 45 parts of alkane solvent; 3 servantate black; 4.5 parts of silica thickening Agent.

[0069]The hydroxysilicide content of the hydroxyrosilicone oil is 1.5%, and the viscosity of 15 ° C at ambient temperature is 15 mp.

[0070]The lateral direction of the elastic fabric is 294%, and the recovery rate is 98.4%. The elastic glue penetration depth is 1 / 3 elastic fabric thickness. The thickness of the fluff fiber is twice the thickness of the elastic fabric.

[0071]The lateral direction opening degree of the elastic adhesive 2 region of the elastic fabric 1 is 293%, and the recovery rate is 98.4%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap