A kind of open width continuous dyeing method of polyester fleece knitted fabrics

A technology for wool knitted fabrics and dyeing methods, which is applied in the field of open-width continuous dyeing of polyester raised knitted fabrics, can solve the problems of poor color fastness of fabrics, color difference between wool surface and smooth surface, etc., achieve soft hand feeling, reduce waste water discharge, and improve fabric quality The effect of performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

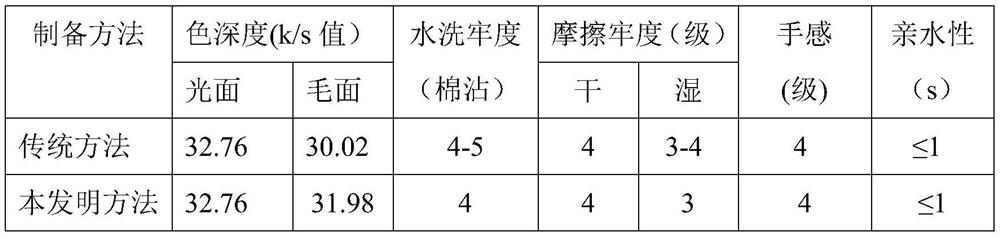

Embodiment 1

[0031] A method for dyeing high-quality polyester raised knitted fabric clothing products, specifically comprising the following steps:

[0032] Step 1, the gray cloth is opened and inspected for the whole cloth. After the gray cloth is unpacked, the process is completed on the opening machine and the cloth inspection machine. Inspection, the open-width finishing of qualified fabrics is placed on the stacking car according to the variety, and the cloth inspection of the gray cloth is completed;

[0033] Step 2: pre-setting the fabric on a sizing machine at a temperature of 180°C for 30 seconds; then remove the oil stains on the fabric through an open-width continuous degreasing machine, and pad in 15g / L degreaser at room temperature , and then steam stacking (100°C, 20 minutes), hot water washing and cold water washing on the cloth in sequence;

[0034] Step 3: Carry out water rolling and vacuum water absorption on the cloth, the excess rate is 30%, the liquid carrying rate o...

Embodiment 2

[0041] A method for dyeing high-quality raised polyester knitted fabrics for clothing, specifically comprising the following steps:

[0042] Step 1, the gray cloth is opened and inspected for the whole cloth. After the gray cloth is unpacked, the process is completed on the opening machine and the cloth inspection machine. Inspection, the open-width finishing of qualified fabrics is placed on the stacking car according to the variety, and the cloth inspection of the gray cloth is completed;

[0043] Step 2: Pre-setting the fabric on a sizing machine at a temperature of 190°C for 35 seconds; then remove the oil stains on the fabric through an open-width continuous degreasing machine, and pad in 10g / L degreaser at room temperature , and then steam the cloth, the temperature is 101 ℃, and the time is 15 minutes;

[0044] Step 3, tenter drying is carried out on the cloth, the temperature is 210°C, the time is 50s, the warp tension-overfeed is 2%, and the weft tension-width is con...

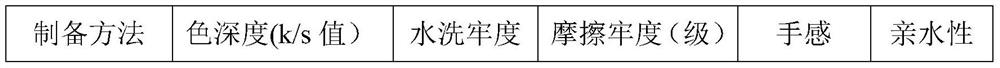

Embodiment 3

[0052] A method for dyeing ordinary raised polyester knitted fabrics, specifically comprising the following steps:

[0053] Step 1, the gray cloth is opened and inspected for the whole cloth. After the gray cloth is unpacked, the process is completed on the opening machine and the cloth inspection machine. Inspection, the open-width finishing of qualified fabrics is placed on the stacking car according to the variety, and the cloth inspection of the gray cloth is completed;

[0054] Step 2: Pre-setting the fabric on a sizing machine at a temperature of 200°C for 40 seconds; then remove the oil stains on the fabric through an open-width continuous degreasing machine, and pad in 16g / L degreaser at room temperature , and then steam the cloth, the temperature is 102 ℃, and the time is 20 minutes;

[0055] Step 3, carry out water rolling and vacuum water absorption treatment on the cloth, the residual rate is 40%, the liquid carrying rate of vacuum water absorption is set to 25%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com