Bridge anti-collision barrier

A technology of anti-collision guardrails and bridges, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of vehicles rushing out, inability to evacuate, and high material costs, so as to change the impact angle of vehicles, avoid the concentration of impact energy, and avoid large areas The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

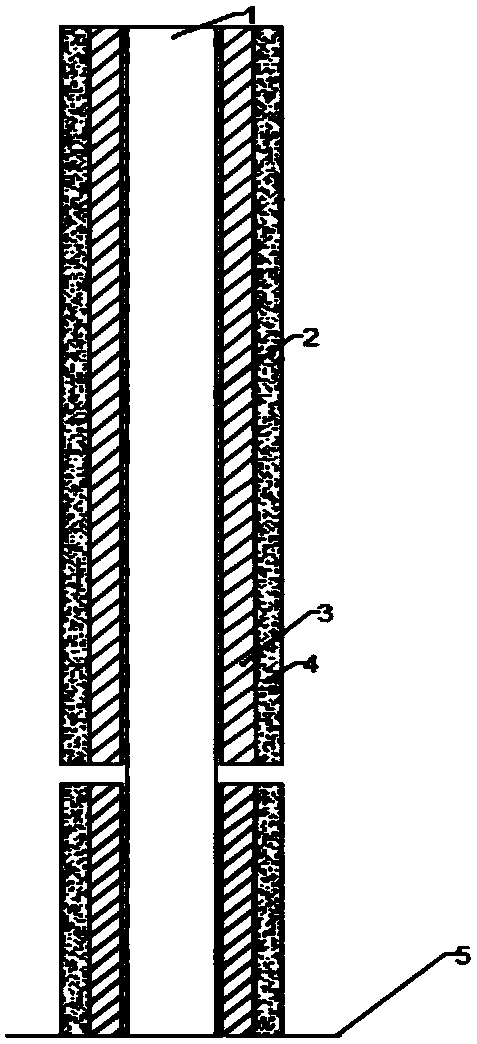

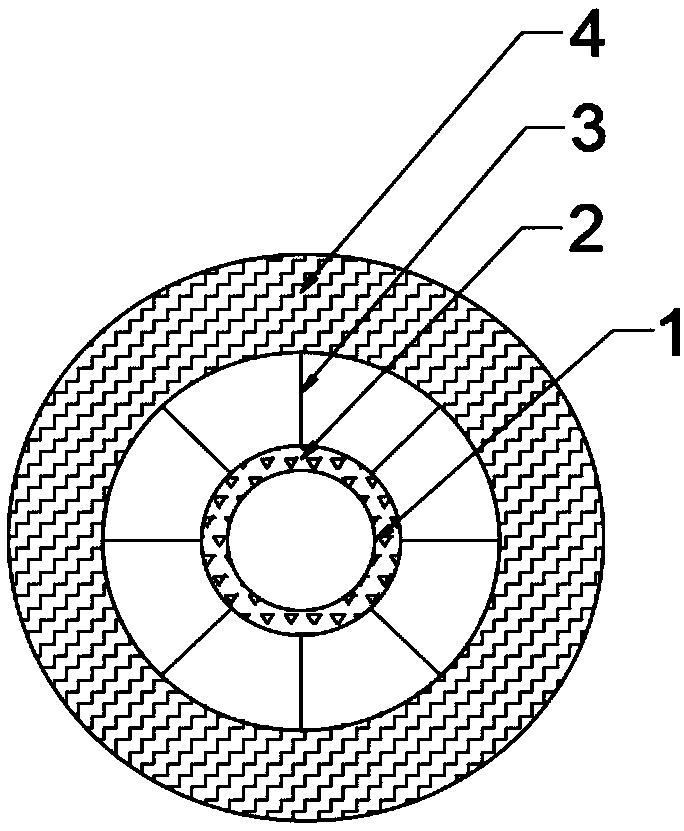

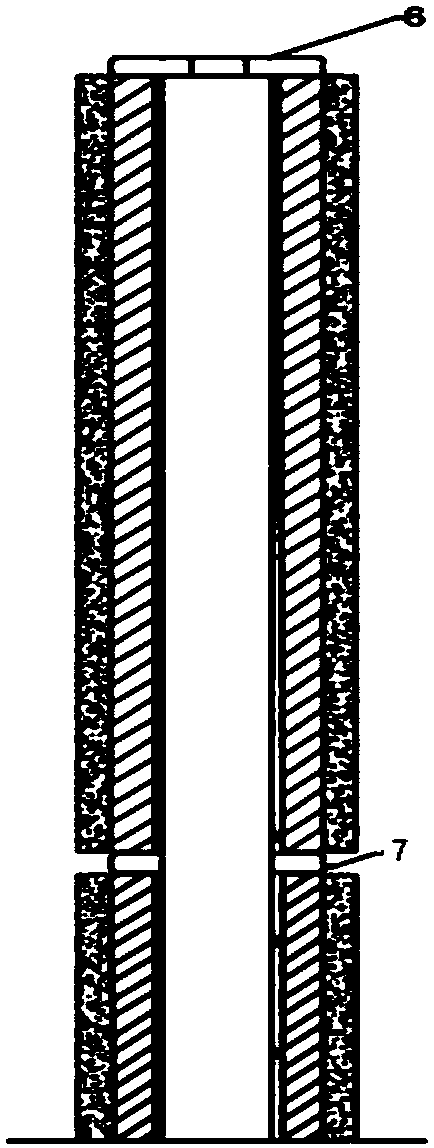

[0031] The application solves the shortcomings existing in the existing bridge guardrail, and provides a guardrail with good energy absorption effect, strong anti-collision performance, and good anti-collision guardrail for preventing vehicles from rushing out of the roadway. In order to achieve the above object, this patent provides a novel crash barrier, such as Figure 1-4 As shown, it includes a stainless steel cylinder column 1, a bearing 2, a stainless steel energy-absorbing member 3 outside the bearing 2, and an energy-absorbing buffer rubber protective sleeve 4 on the outside of the stainless steel energy-absorbing member 3. The lower end of the stainless steel cylinder column 1 is provided with a circular fixed disk base 5 .

[0032] Such as figure 2 As shown, the stainless steel energy-absorbing member 3 is supported and connected by 8 steel sheets evenly distributed in the circumferential direction between two steel cylinders with different diameters, and the 8 su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com