Auxiliary hole digging device for detecting roadbed solidity based on sand filling method

A technology of sand filling method and roadbed, which is applied in basic structure engineering, soil mover/excavator, on-site foundation soil survey, etc., which can solve the problem of low efficiency, high requirements for operators, and the bottom flatness detection hole of the detection hole The side arc can not be guaranteed and other problems, to achieve the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

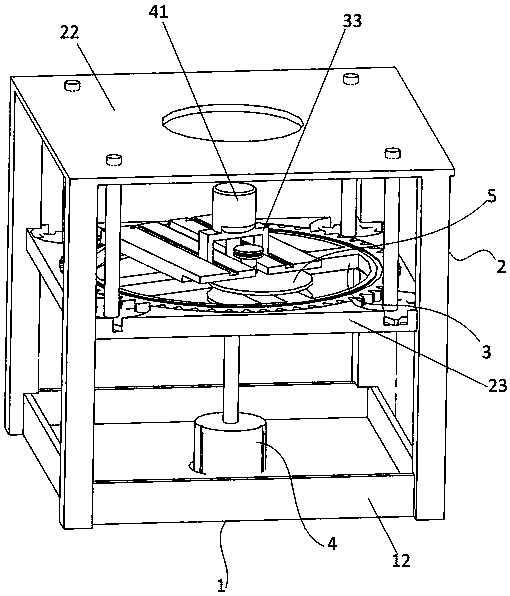

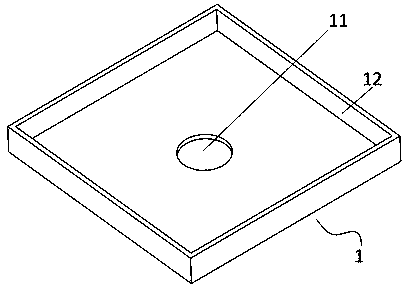

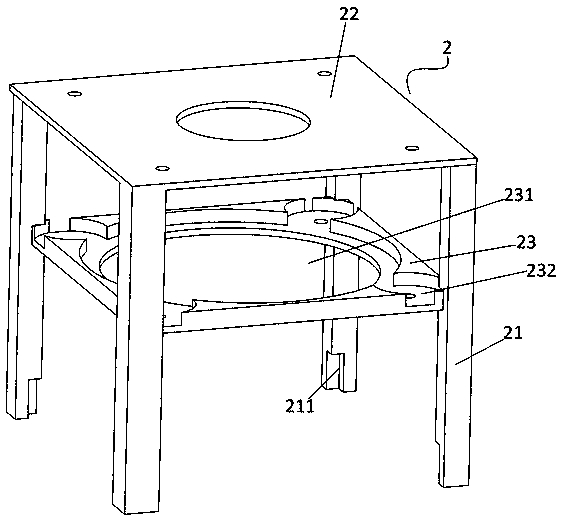

[0064] Please refer to Figure 1 to Figure 8 , the present invention proposes an auxiliary hole-digging device for detecting the solidity of the roadbed by sand filling method, which includes a base plate 1 , a bracket 2 , a first transmission assembly 3 , a second transmission assembly 4 and a third transmission assembly 5 .

[0065] Wherein, the base plate 1 is used to contain the excavated soil, and the excavating cylinder 43 is limited to ensure that the diameter of the trimmed detection hole is equal to that of the circular hole 11 on the base plate 1 . The bracket 2 is used to carry the entire auxiliary hole digging device. The first transmission assembly 3 is used to adjust the position of the excavator 43 in the circumferential direction, and the second transmission assembly 4 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com