High-pressure air multi-tube concrete spraying device

A technology of concrete spraying and high-pressure air, which is applied to shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of detachment from surrounding rock, concrete rebound and splashing, etc., and achieve the effect of improving efficiency, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

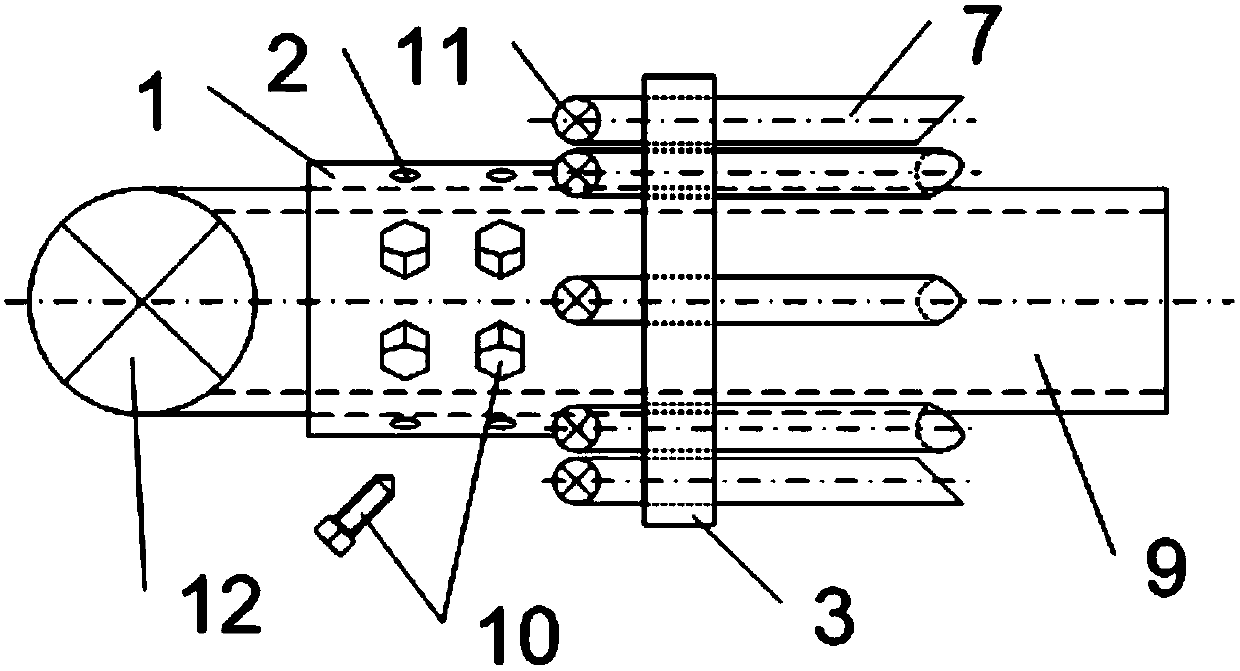

[0029] combined with figure 1 As shown, a high-pressure air multi-tube concrete injection device related to the present invention includes a concrete injection device and a high-pressure air injection device.

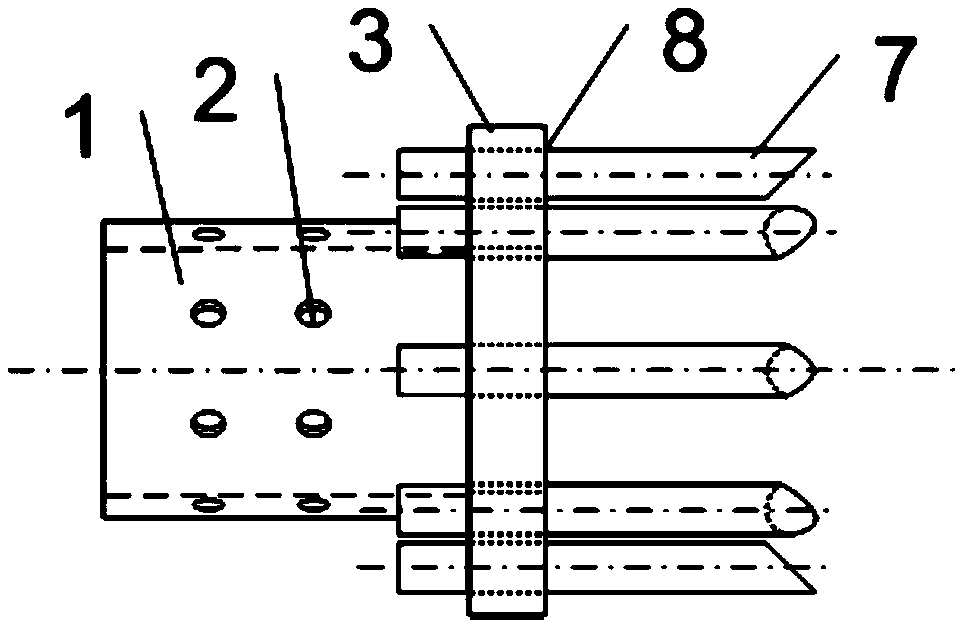

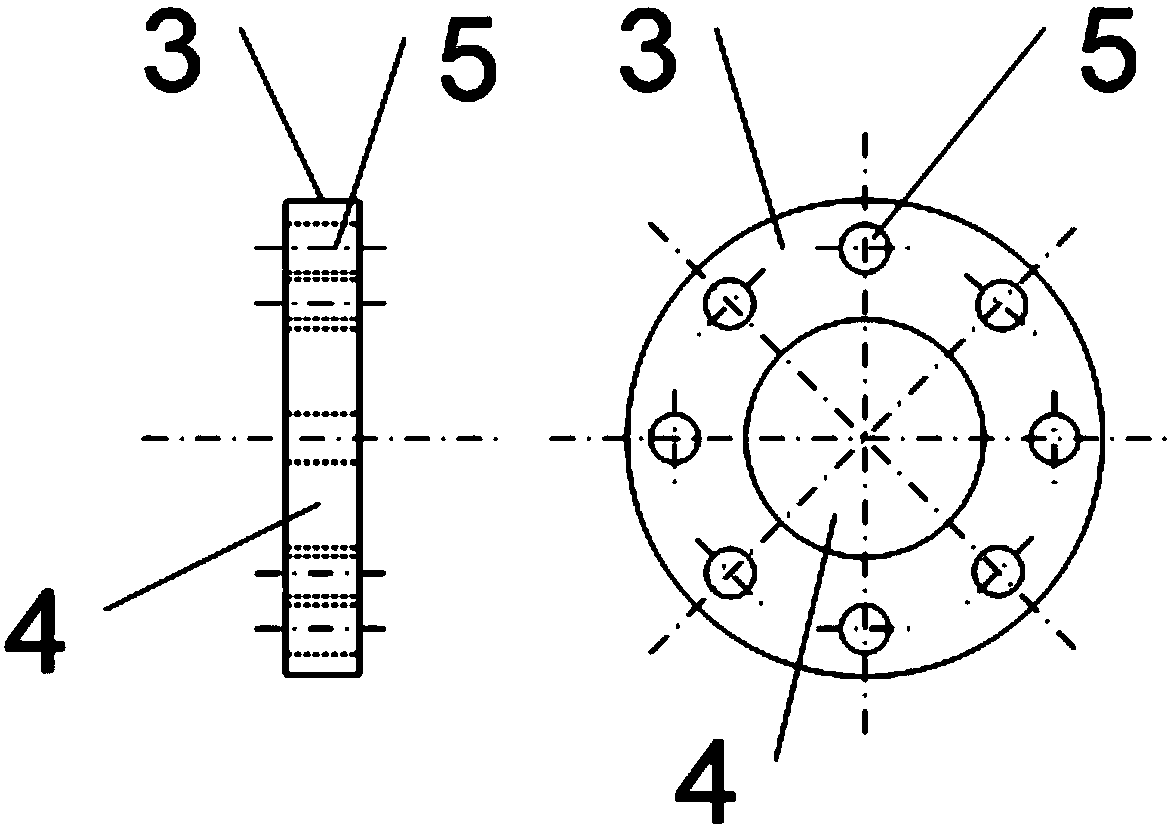

[0030] combined with figure 1 with 2 As shown, the high-pressure air injection device includes a nozzle fixing ring 1 , an end plate 3 and an air nozzle 7 . The structure of end plate 3 is as attached image 3 As shown, the end plate 3 is an annular plate made of steel plate, and its thickness is determined according to calculation. The center of the end plate 3 is provided with a concrete spray gun insertion hole 4, and the surroundings of the concrete spray gun insertion hole 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com