Heat exchanger tube bundle wall corrosion condition ultrasonic detection bracket and using method

A technology for ultrasonic testing and heat exchangers, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

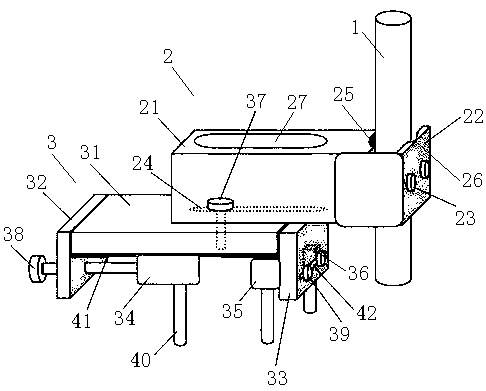

[0019] Example figure 1 As shown, the bracket for ultrasonic testing of the corrosion condition of the tube wall of the heat exchanger tube bundle of the present invention includes a conduit 1, a clamping frame 2 and a fixed base 3;

[0020] The clamping frame 2 includes a clamping block 21, a clamping angle steel 22 and a fastening screw 23, the bottom surface of the clamping block 21 is provided with a limit slot 24, and one side of the clamping angle steel 22 is arranged on the clamping On one side of the block 21, the fastening bolt 23 is screwed on the other side of the clamping angle steel 22, and the conduit 1 is vertically arranged between the end face of the clamping block 21 and the other side of the clamping angle steel 22 and passes through the Said fastening screw 23 is fixed;

[0021] The fixed base 3 includes a bottom plate 31, a first end plate 32, a second end plate 33, a first slider 34, a second slider 35, a third slider 36, a limit screw 37, a long bolt 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com