A low boiling point insulating liquid insulation characteristic test chamber

A technology for testing insulating liquids and characteristics, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve problems such as poor stability, fixed structure, fixed, etc., to avoid changes in physical properties, control human errors, and optimize test devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

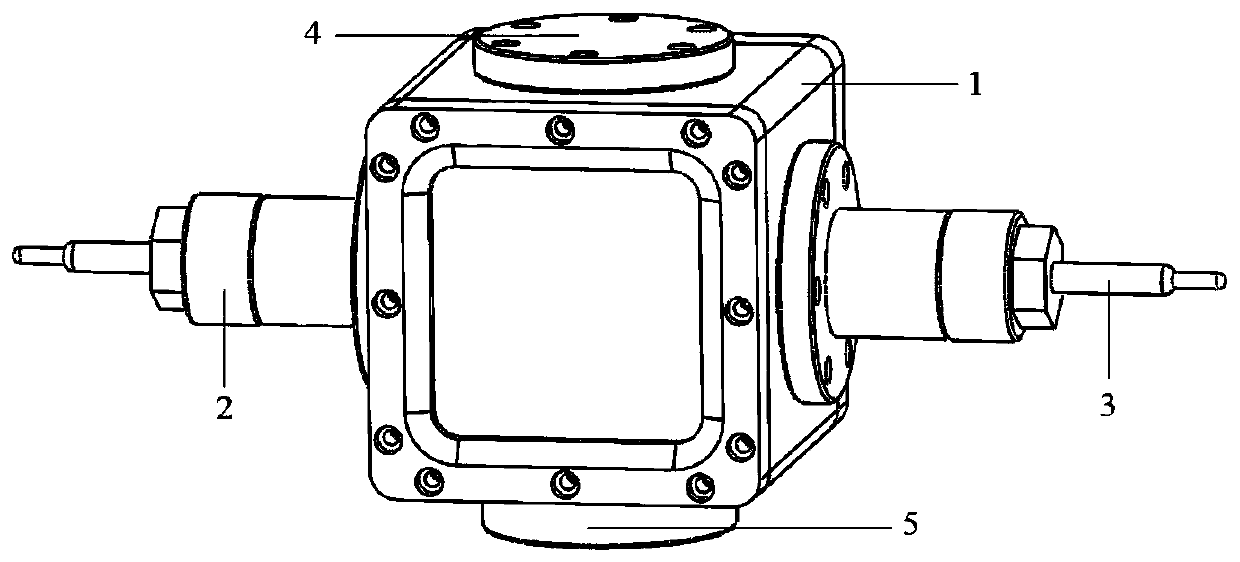

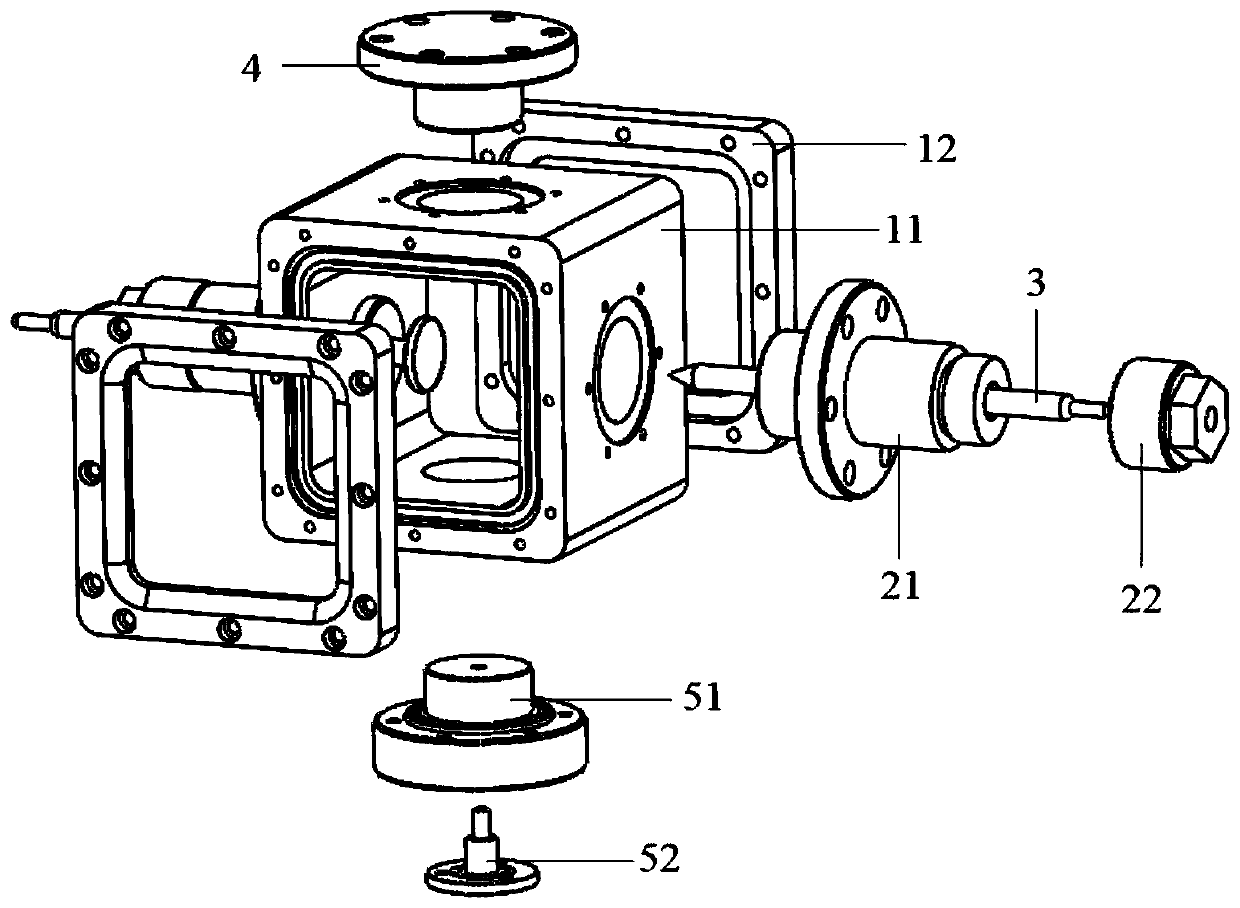

[0040] This embodiment provides a low-boiling point insulating liquid insulation characteristic test chamber, which is specifically a horizontal test structure. In the test, the pole gap is set horizontally, and the direction of bubble flow generated by the heating source is longitudinal, which is set perpendicular to the pole gap; this embodiment The specific structure of the insulation characteristics test chamber for low boiling point insulating liquids is as follows: Figure 1-3 As shown, it includes a cavity 1, an insulating sleeve flange 2, an electrode 3, a blind flange 4 and a transverse heating flange mechanism 5;

[0041] The cavity 1 includes a cavity body 11 and an observation window 12. The cavity body 11 is a hollow rectangular shell structure. The observation window 12 is fixed to the front and rear ends of the cavity body 11 by bolts. The four side walls of the cavity body 11 are respectively One flange mounting hole is provided, and the four flange mounting holes...

Embodiment 2

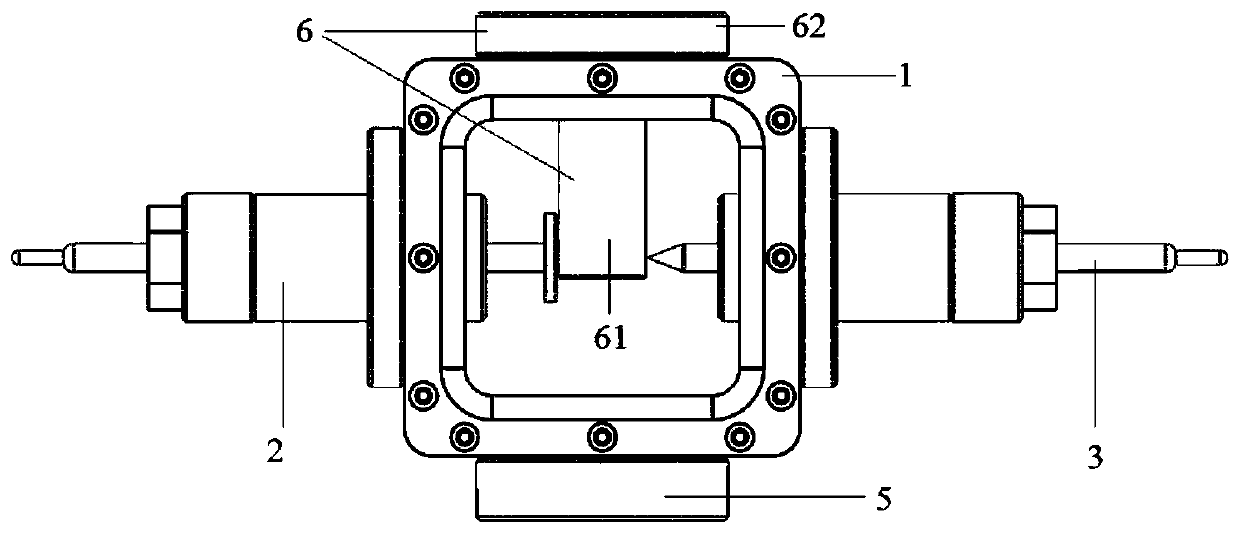

[0048] This embodiment also provides a low-boiling point insulating liquid insulation characteristic test cavity. The difference between this embodiment and the first embodiment is only that this embodiment provides a longitudinal test cavity in which the pole gap is arranged longitudinally in the test. The bubble flow direction generated by the heating source is also longitudinal, and the bubble flow direction is set parallel to the pole gap;

[0049] Such as Figure 4 , Figure 5 As shown, the technical solution of this embodiment different from the first embodiment is only:

[0050] The insulating sleeve flange 2 is installed at the flange mounting hole on the top of the cavity body 11. There are two blind plate flanges 4, and the two blind plate flanges 4 are respectively installed on the two flanges on both sides of the cavity body 11. In the hole, the longitudinal heating flange mechanism 7 is installed at the flange installation hole at the bottom of the cavity body 11;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com