Control method of tea frying machine using laser probe to detect tea height

A technology of laser probe and control method, which is applied in the direction of adopting optical device, control/adjustment system, non-electric variable control, etc., can solve the problems of tea quality degradation, excessive or too small tea force, uncontrollable size, etc., to achieve Improvement of effect, improvement of applicability, effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

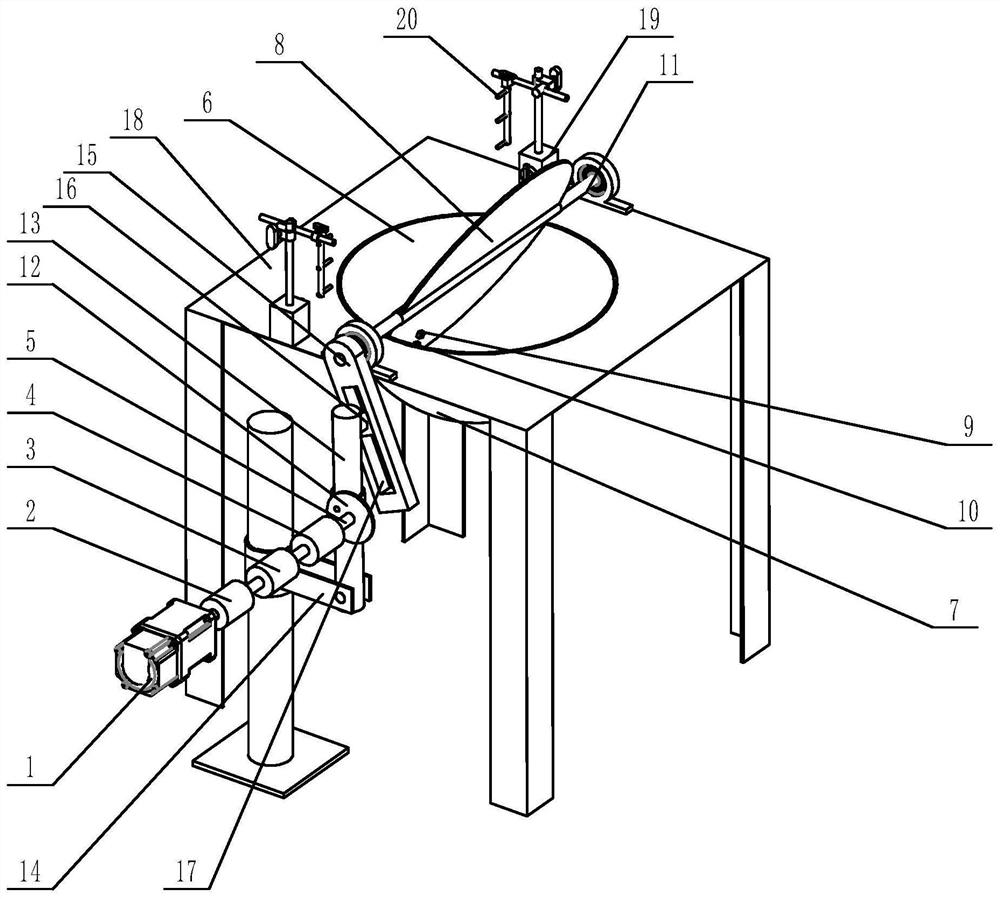

[0029] Such as figure 1 As shown, a tea frying machine control method using a laser probe to detect the height of tea leaves is used to control the tea frying machine in sections. The tea frying machine includes a frame 18, a height detection device, a motor 1, and a first shaft coupling 2, torque sensor 3, second coupling 4, transmission shaft 11, frying pan 6, heating wire 7, frying plate 8, speed sensor 9 and temperature sensor 10, and the motor 1 and frying pan 6 are fixed on the machine On the frame 18, the output shaft 5 of the motor 1 is sequentially connected to the first coupling 2, the torque sensor 3 and the second coupling 4, and the output shaft 5 of the second coupling 4 is connected to the transmission shaft through the crank rocker mechanism 11. The frying plate 8 is fixed on the transmission shaft 11. The shape of the lower part of the frying plate 8 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com