Feed preservation warehouse

A feed and crossbar technology, applied in the agricultural field, can solve the problem of mold-proof dead ends in feed, and achieve the effect of reducing mildew in feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

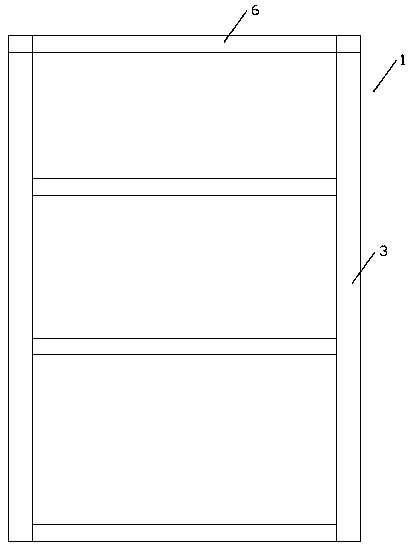

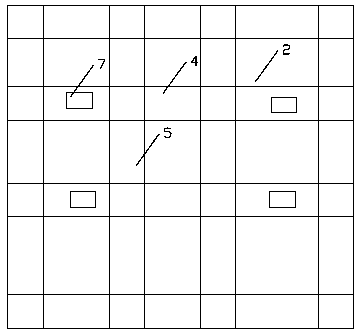

[0021] A feed storage warehouse includes a frame body 1 and a plurality of horizontal movable rods 2 arranged inside the frame body 1, and longitudinal fixed rods 3 are arranged around the frame body 1, and the lateral movable rods 2 are sleeved on the longitudinal fixed rods 3, The horizontally movable rod 2 includes a cross bar 4 in the X-axis direction and a cross bar 5 in the Y-axis direction. The cross bar 4 in the X-axis direction and the cross bar 5 in the Y-axis direction are arranged intersectingly. Rod 6 , the ends of the horizontal bar 4 in the X-axis direction and the horizontal bar 5 in the Y-axis direction are sleeved on the guide rod 6 . This application can realize the adjustment of the space size in the storage warehouse through the horizontal and horizontal movement of the horizontal bar 4 in the X-axis direction and the horizontal bar 5 in the Y-axis direction, and the vertical movement, avoiding the storage of too much feed through accumulation, and can do ...

Embodiment 2

[0023] A feed storage warehouse includes a frame body 1 and a plurality of horizontal movable rods 2 arranged inside the frame body 1, and longitudinal fixed rods 3 are arranged around the frame body 1, and the lateral movable rods 2 are sleeved on the longitudinal fixed rods 3, The horizontally movable rod 2 includes a cross bar 4 in the X-axis direction and a cross bar 5 in the Y-axis direction. The cross bar 4 in the X-axis direction and the cross bar 5 in the Y-axis direction are arranged intersectingly. Rod 6 , the ends of the horizontal bar 4 in the X-axis direction and the horizontal bar 5 in the Y-axis direction are sleeved on the guide rod 6 . A lifting frame 7 is arranged on the edge of the cross bar 4 in the X-axis direction and the cross bar 5 in the Y-axis direction, and the lifting frame 7 is lifted upwards by a cylinder. The X-axis direction cross bar 4 and the Y-axis direction cross bar 5 are provided with motors, and the motor reverses the X-axis direction cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com