A Periodic Magnet Assembly That Generates Torsion Orbits and Increases Axial Focusing Force

A magnet assembly and periodic technology, used in electrical components, magnetic resonance accelerators, accelerators, etc., can solve problems such as insufficient axial focusing force, and achieve the effect of improving axial focusing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

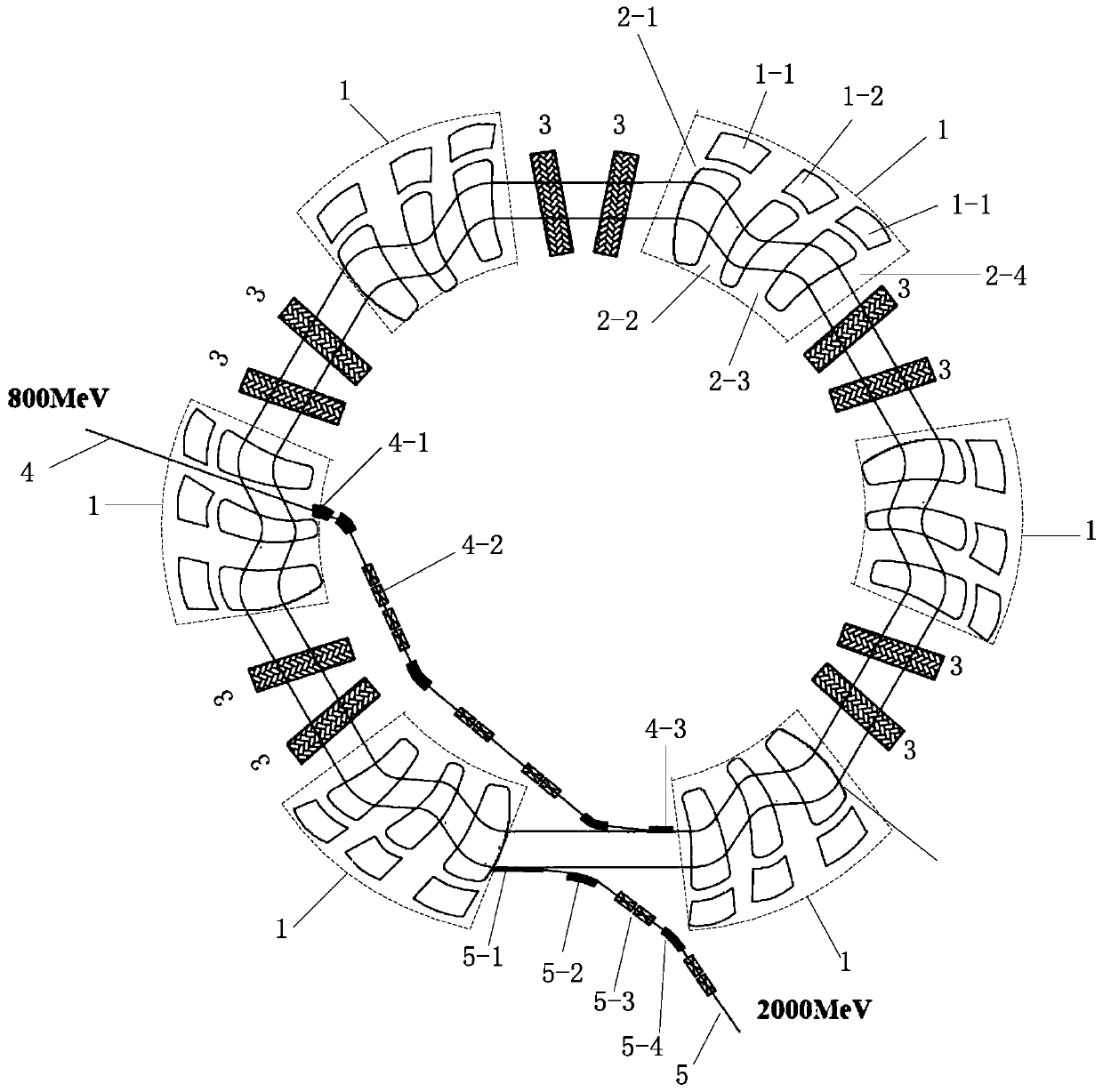

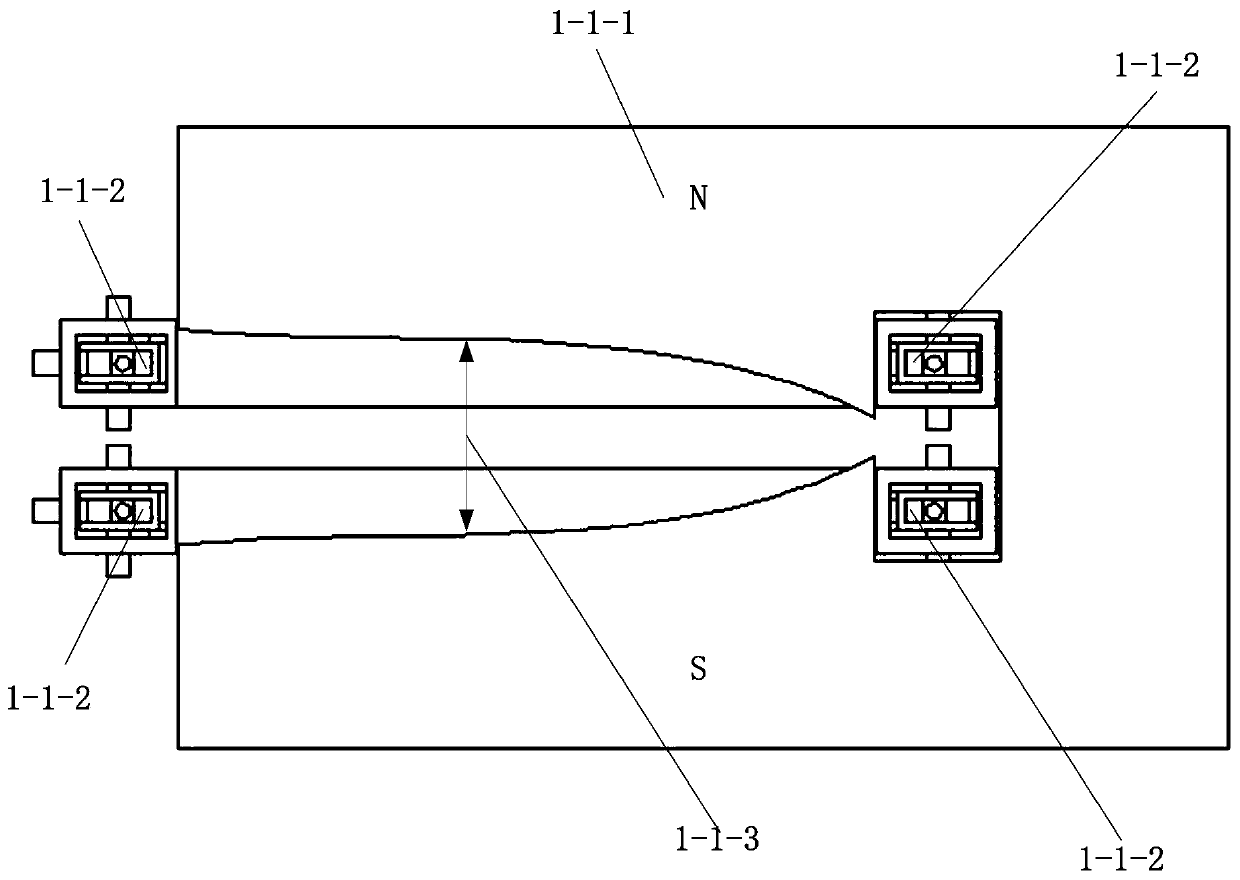

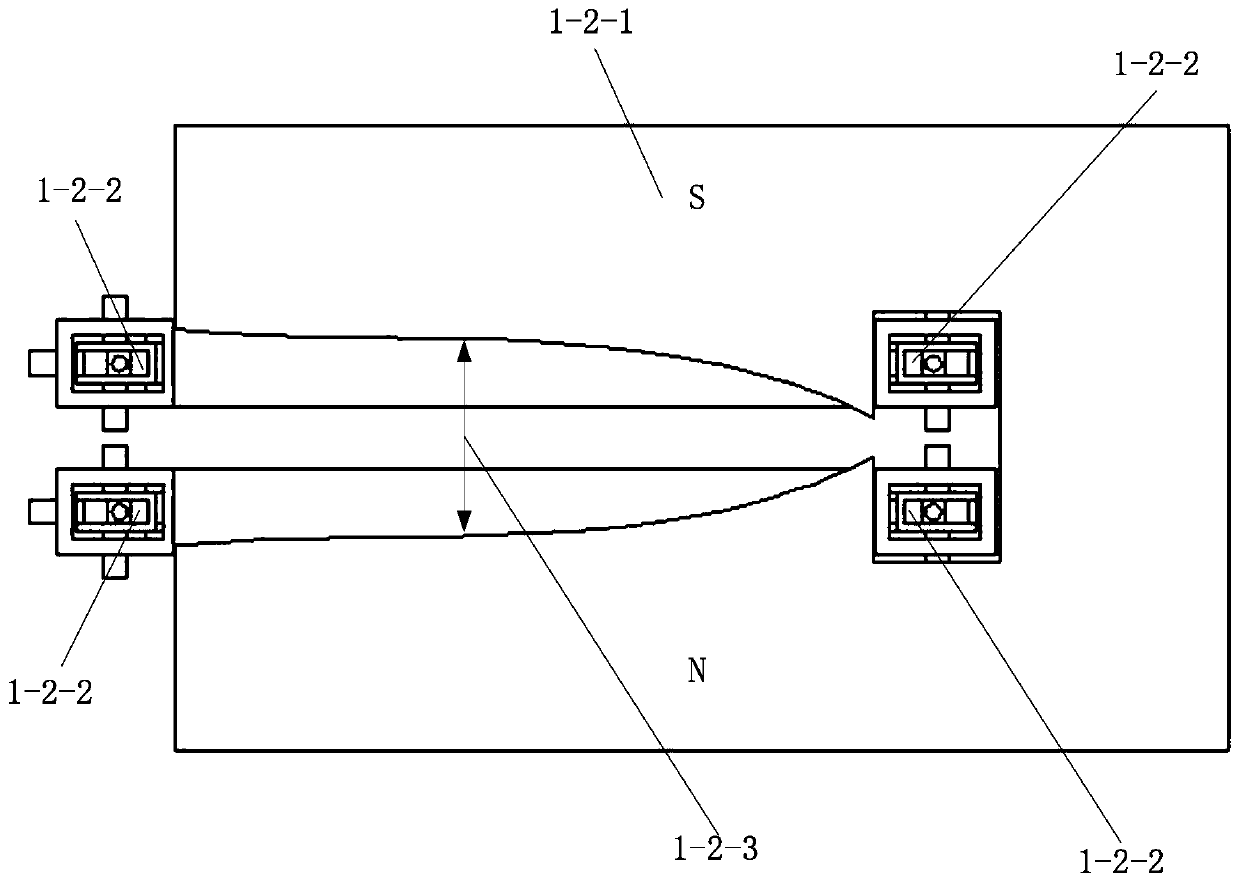

[0040] 1. Beam focusing process. In one cycle, the beam first moves linearly in the first long drift section 2-1 of the magnet assembly that periodically generates the torsion track (because there is no magnetic field in the drift section, the particles move linearly without a magnetic field), and after When the first radial focusing magnet 1-1 deflects forward, the beam deflects toward the center of the circle, and at the same time produces a defocusing effect in the axial direction; next, in the first short drift section 2-2 of the magnet assembly that periodically generates twisted orbits The beam moves in a straight line through the first reversely deflected axial focusing magnet 1-2, and the beam deflects outward from the center of the circle, while producing a focusing effect in the axial direction. After passing through the second short drift section 2-3 of the magnet assembly that periodically generates the torsion track, the beam deflects toward the center of the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com