A Large-Range Variable Orbit Magnet Structure for Continuous Beam Acceleration

A large-scale, orbital technology, applied in the direction of magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problems of beam extraction energy limitation, beam energy improvement, etc., to improve focusing intensity, avoid divergence, and break through the extraction of beam current The effect of energy restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

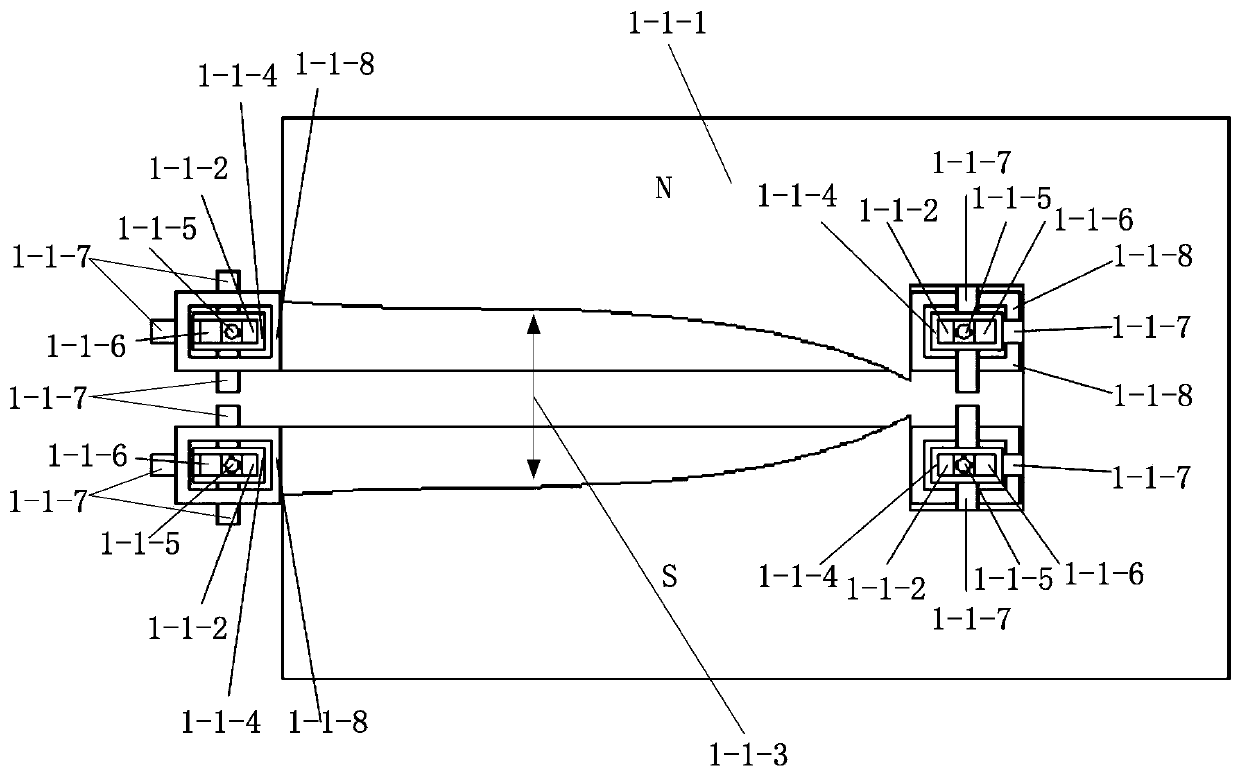

[0044] In this embodiment, the relationship between the magnetic air gap and the radius is as attached Figure 6 As shown, the relationship between the magnetic field curve and the radius is as Figure 7 shown.

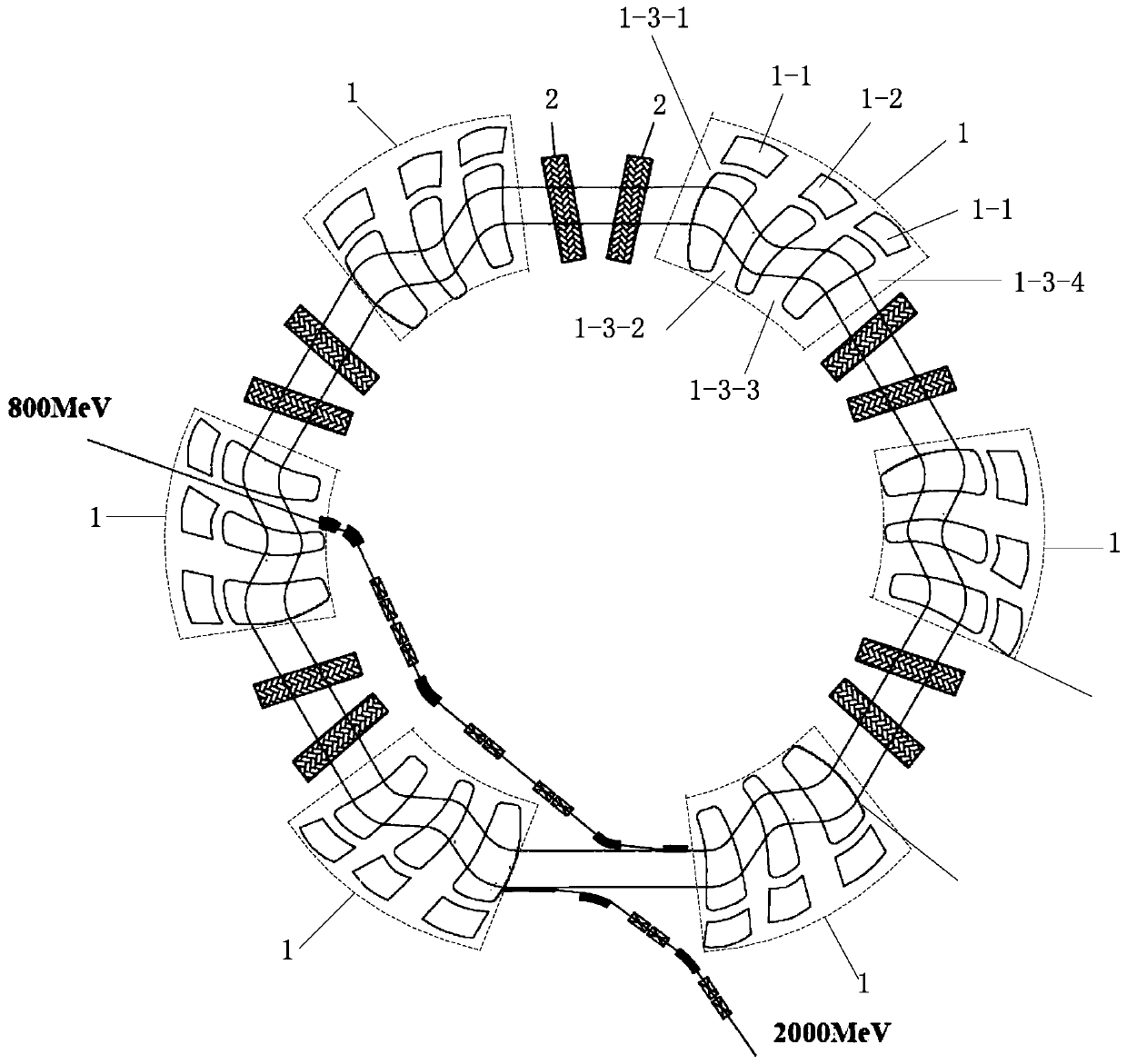

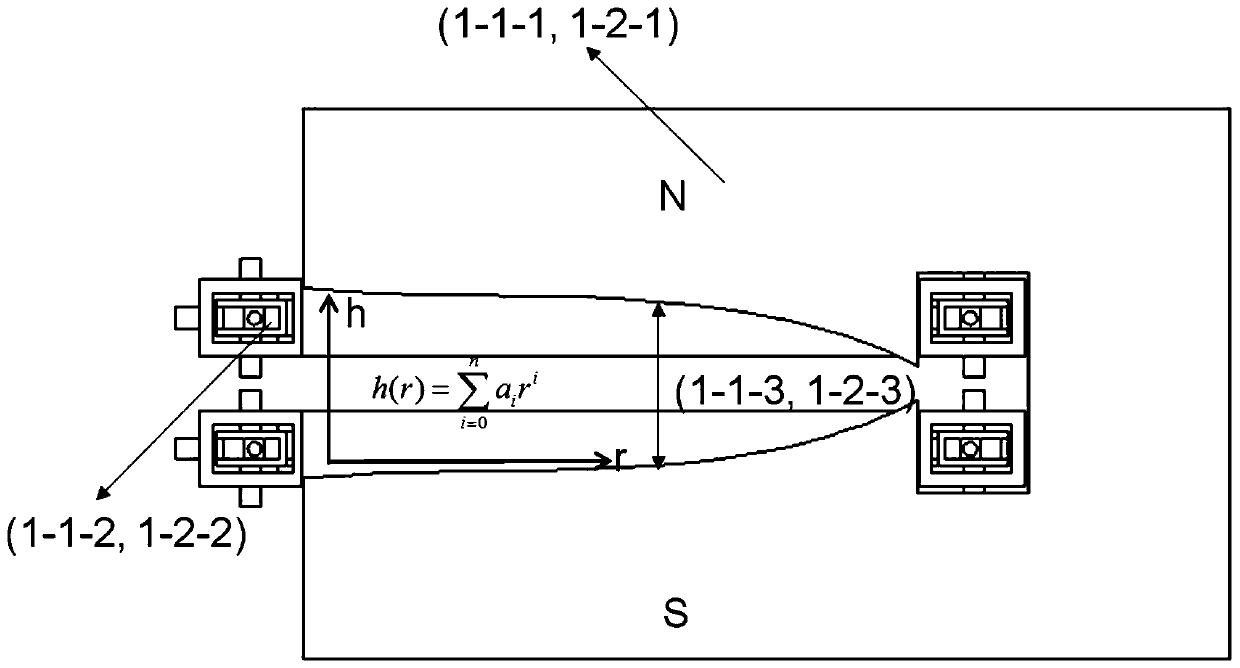

[0045] This embodiment can realize the constrained proton beam injected from 800MeV and accelerated to 2GeV magnet assembly structure in the way of continuous beam acceleration. Among them, the average radii of the beam orbits of 800MeV and 2GeV are 16.28 meters and 18.33 meters respectively. The minimum field strength of the defocused magnet is 0.59 Tesla, the highest field strength is 2.48 Tesla, the magnet width is 1.82 meters, the half-height of the magnetic air gap at the widest point in the radial direction is 25 mm, and the half-height of the central magnetic air gap is 188.62 mm.

[0046] The orbit change refers to that as the energy of the beam continues to increase, the radius of the orbit that the beam runs also increases continuously. The change in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com