Electronically controllable pneumatic brake system in a utility vehicle and method for electronically controlling a pneumatic brake system in a utility vehicle

A pneumatic braking, electronic control technology, applied in the direction of brake transmission, control valve and air release valve, brake, etc., can solve the problem of difficult modification, increase assembly cost and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

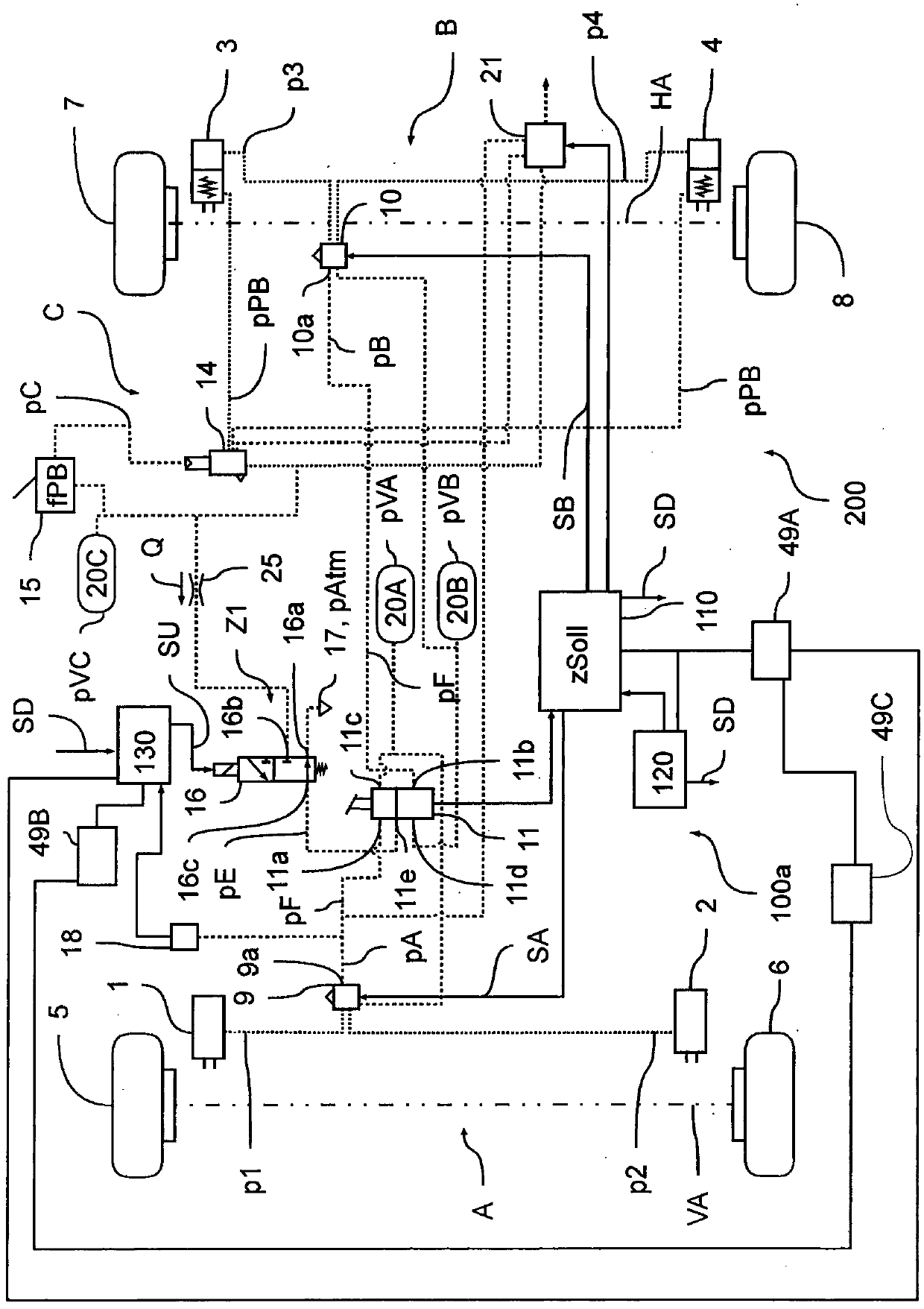

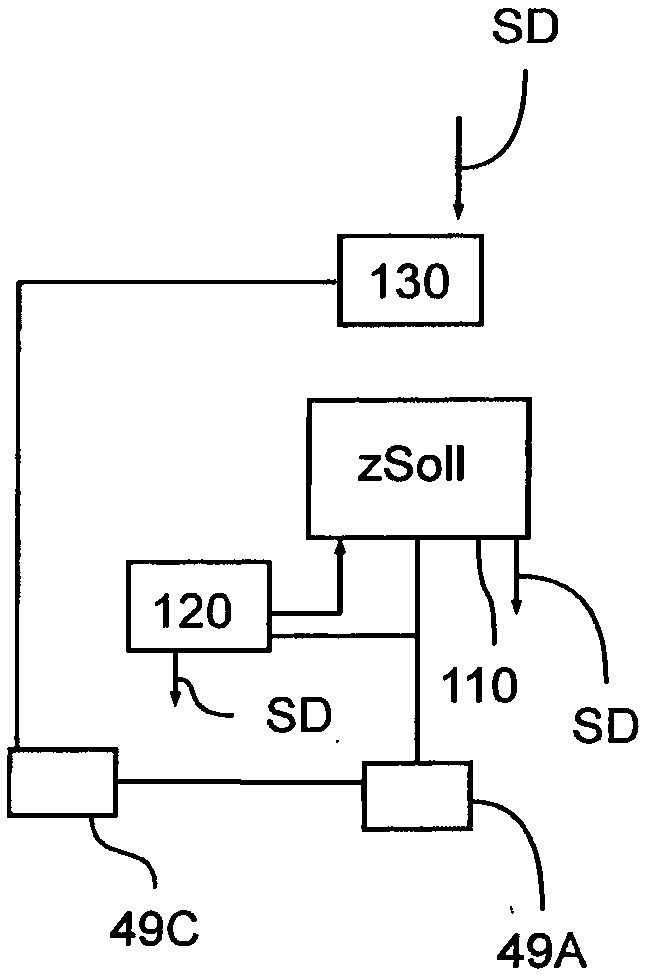

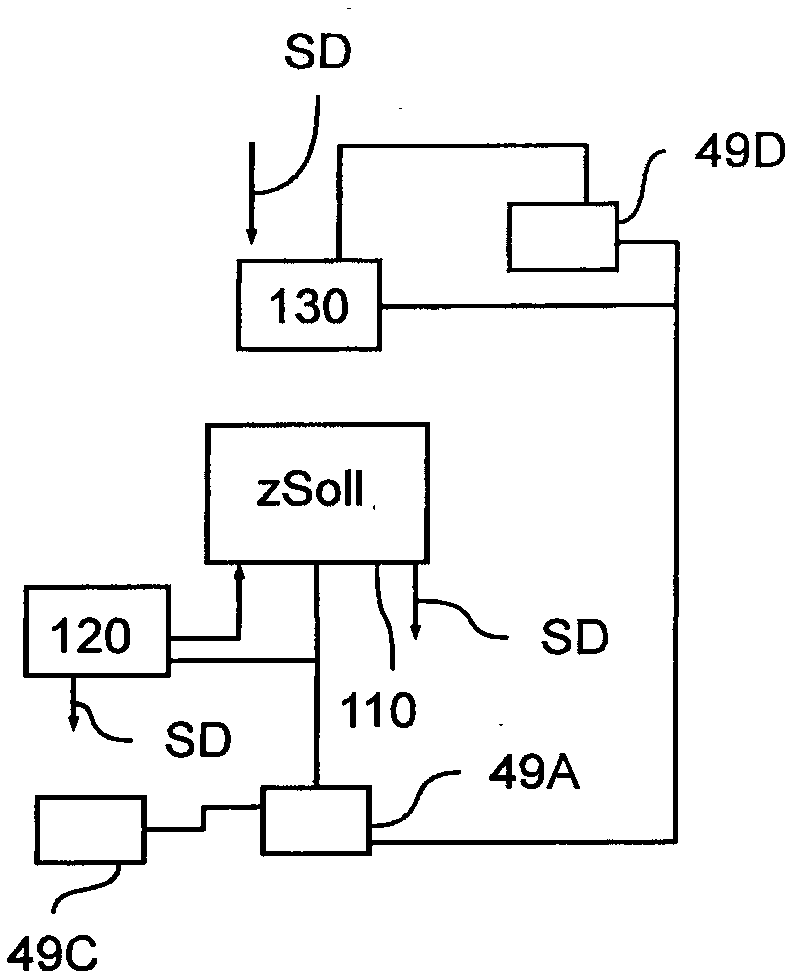

[0050] in accordance with Figure 1a In the embodiment of the present invention, a section of an electropneumatic braking system 100a of a vehicle 200, in particular a commercial vehicle, is shown as a block diagram, wherein the electropneumatic braking system is implemented as an EBS braking system 100a, that is to say brake pre-braking It is assumed to be implemented purely electrically in normal operation. For this purpose, EBS braking system 100 a has four wheel brakes 1 , 2 , 3 , 4 which are used to decelerate wheels 5 , 6 , 7 , 8 of vehicle 200 . For deceleration, three brake circuits A, B, C are provided, each of which is assigned a pressure medium reservoir 20A, 20B, 20C in order to supply the respective brake circuit A, B, C with pressure medium and thus be able to A build-up of brake pressures p1 , p2 , p3 , p4 , pPB for the respective wheel brakes 1 , 2 , 3 , 4 is achieved. In each pressure medium accumulator 20A, 20B, 20C there is a corresponding reserve pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com