Oilseed rape harvester

A harvester, rapeseed technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of easy cuts caused by sickles, small harvesting area, etc., to reduce workload, high safety, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

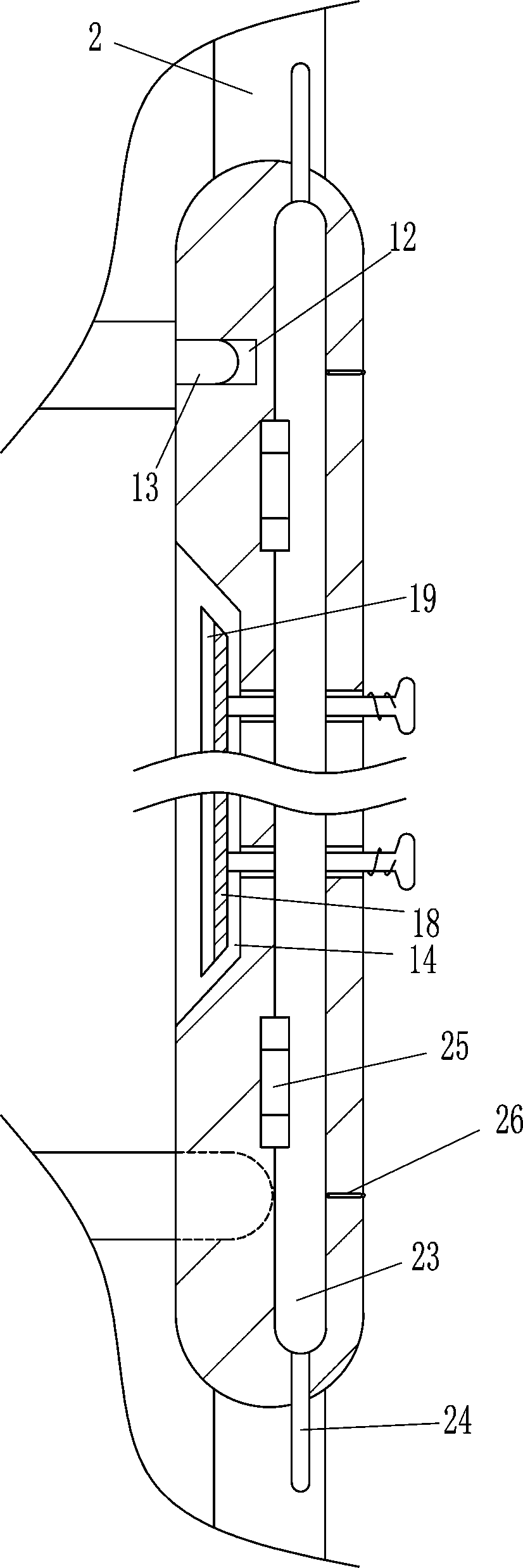

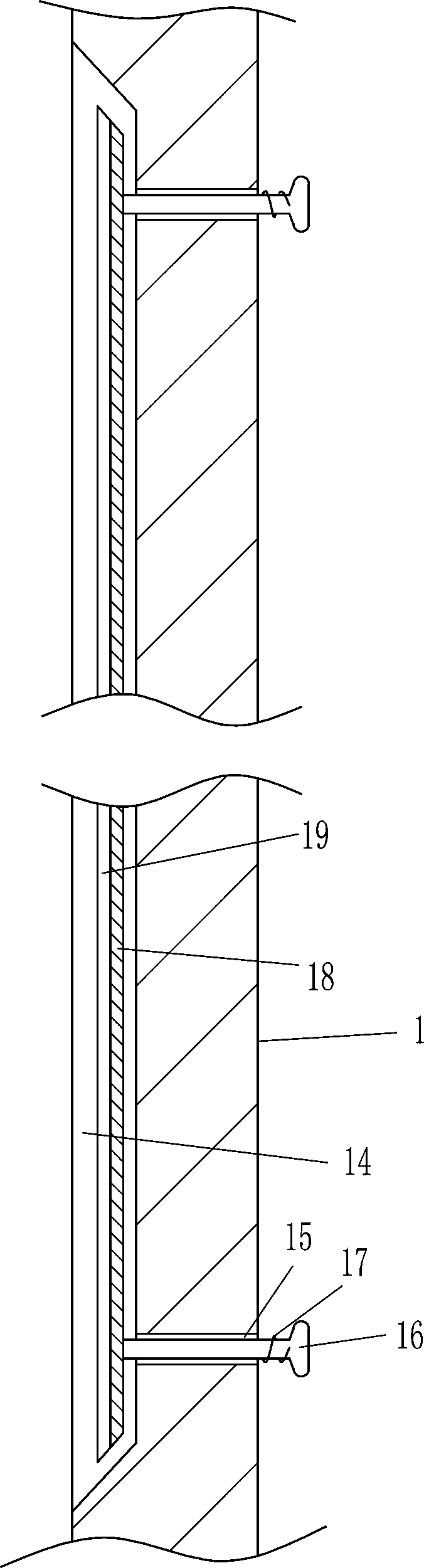

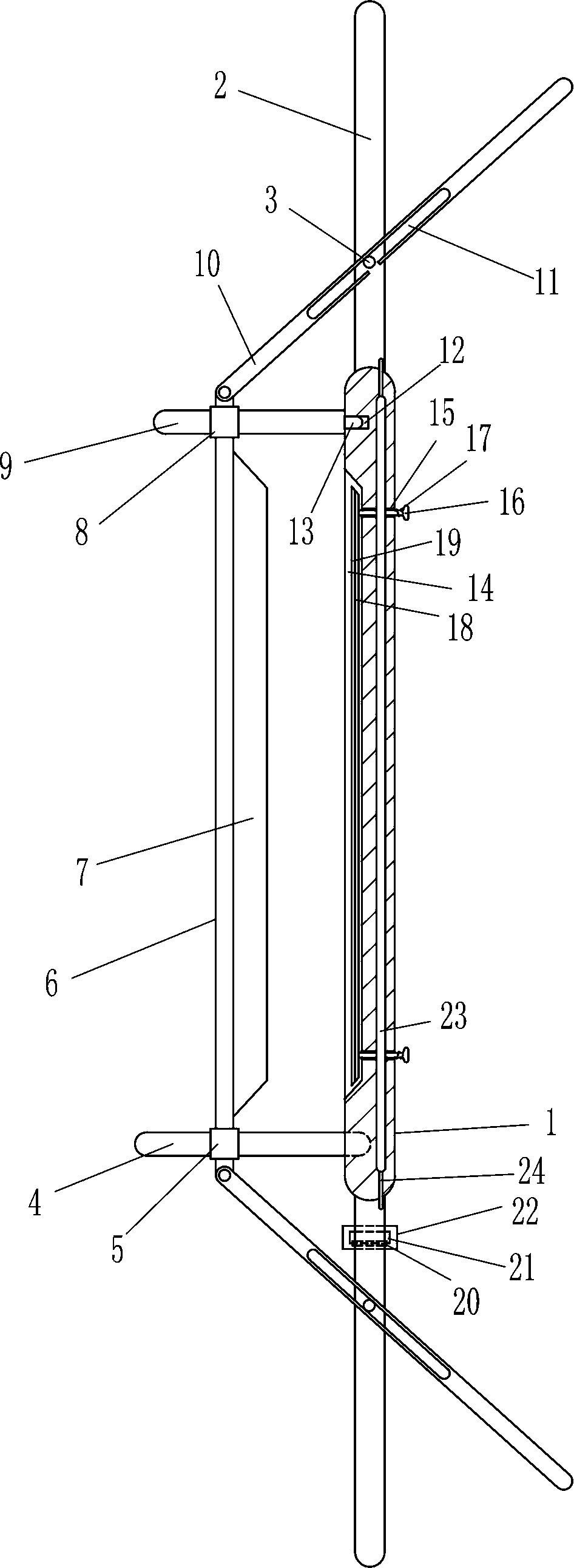

[0020] A kind of rape harvester, such as Figure 1-4 As shown, it includes a mounting rod 1, a grip rod 2, a sliding shaft 3, a first sliding rod 4, a first sliding sleeve 5, a moving rod 6, a cutter 7, a second sliding sleeve 8, a second sliding rod 9, and a booster Rod 10 and insert block 13, the front and rear ends of installation rod 1 are provided with grip rod 2, the top of grip rod 2 is provided with sliding shaft 3, the front side of the bottom of installation rod 1 is provided with first slide rod 4, on the first slide rod 4 The sliding type is provided with a first sliding sleeve 5, and a slot 12 is provided at the rear of the left side of the mounting rod 1, and an insert block 13 is placed in the slot 12, and the left side of the insert block 13 is provided with a second slide bar 9, and the second slide bar 9 The upper sliding type is provided with a second sliding sleeve 8, the second sliding sleeve 8 and the first sliding sleeve 5 are provided with a moving rod ...

Embodiment 2

[0022] A kind of rape harvester, such as Figure 1-4 As shown, it includes a mounting rod 1, a grip rod 2, a sliding shaft 3, a first sliding rod 4, a first sliding sleeve 5, a moving rod 6, a cutter 7, a second sliding sleeve 8, a second sliding rod 9, and a booster Rod 10 and insert block 13, the front and rear ends of installation rod 1 are provided with grip rod 2, the top of grip rod 2 is provided with sliding shaft 3, the front side of the bottom of installation rod 1 is provided with first slide rod 4, on the first slide rod 4 The sliding type is provided with a first sliding sleeve 5, and a slot 12 is provided at the rear of the left side of the mounting rod 1, and an insert block 13 is placed in the slot 12, and the left side of the insert block 13 is provided with a second slide bar 9, and the second slide bar 9 The upper sliding type is provided with a second sliding sleeve 8, the second sliding sleeve 8 and the first sliding sleeve 5 are provided with a moving rod ...

Embodiment 3

[0025] A kind of rape harvester, such as Figure 1-4 As shown, it includes a mounting rod 1, a grip rod 2, a sliding shaft 3, a first sliding rod 4, a first sliding sleeve 5, a moving rod 6, a cutter 7, a second sliding sleeve 8, a second sliding rod 9, and a booster Rod 10 and insert block 13, the front and rear ends of installation rod 1 are provided with grip rod 2, the top of grip rod 2 is provided with sliding shaft 3, the front side of the bottom of installation rod 1 is provided with first slide rod 4, on the first slide rod 4 The sliding type is provided with a first sliding sleeve 5, and a slot 12 is provided at the rear of the left side of the mounting rod 1, and an insert block 13 is placed in the slot 12, and the left side of the insert block 13 is provided with a second slide bar 9, and the second slide bar 9 The upper sliding type is provided with a second sliding sleeve 8, the second sliding sleeve 8 and the first sliding sleeve 5 are provided with a moving rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com