A lower bending die

A technology of bending dies and dies, which is applied in the field of stamping dies, can solve the problems of the bending male dies being difficult to straighten, difficult to process, and the appearance of the bend at the gap is bad, so as to avoid stamping, easy processing, and avoid appearance bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

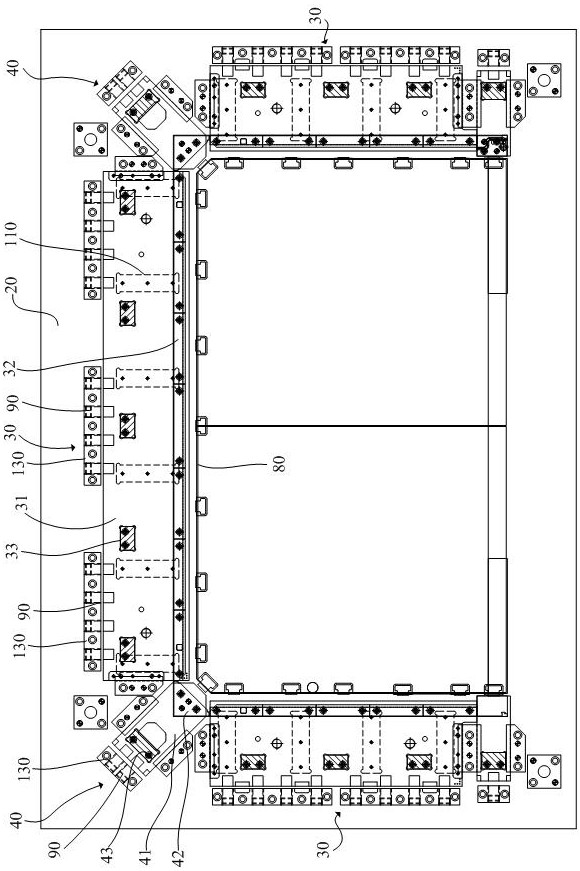

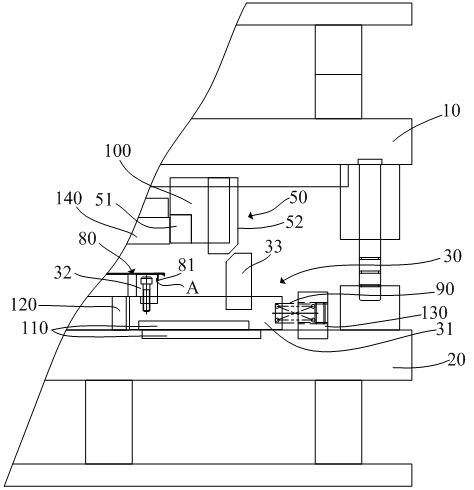

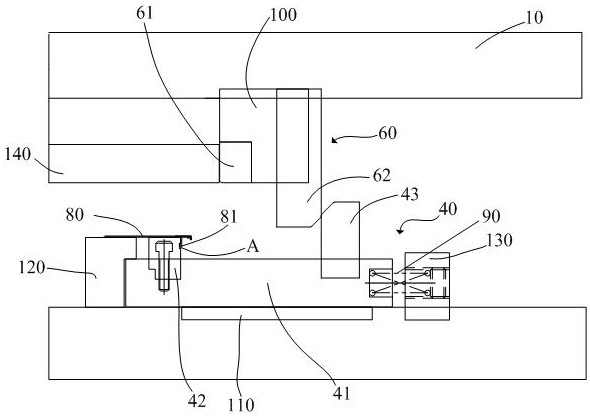

[0024] refer to Figure 1 to Figure 5 In this embodiment, a lower bending mold is used for bending and forming a box-shaped product 80 with three side walls, and the top edge of each side wall has an inwardly folded reflex flange 81. The lower bending mold includes an upper The mold base 10, the lower mold base 20, the bending male die assembly and the punch assembly corresponding to the bending male die assembly, the punch assembly is fixed on the upper die base 20, and the bending male die assembly is located on the lower On the mold base 10; the bending male die assembly includes a side bending male die assembly 30 and a corner bending male die assembly 40 adjacent thereto, and accordingly, the punch assembly includes a side punch assembly 50 and Corner punch assembly 60; side bending male die assembly 30 includes sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com