Calibrator for hydraulic bolt tensioning jack

A hydraulic bolt and tensioner technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not having a hydraulic bolt tensioner calibrator, etc., to achieve the calibration of large-load bolt tensioners and ensure accuracy sex, damage protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principle and features of the device will be described below in conjunction with the accompanying drawings.

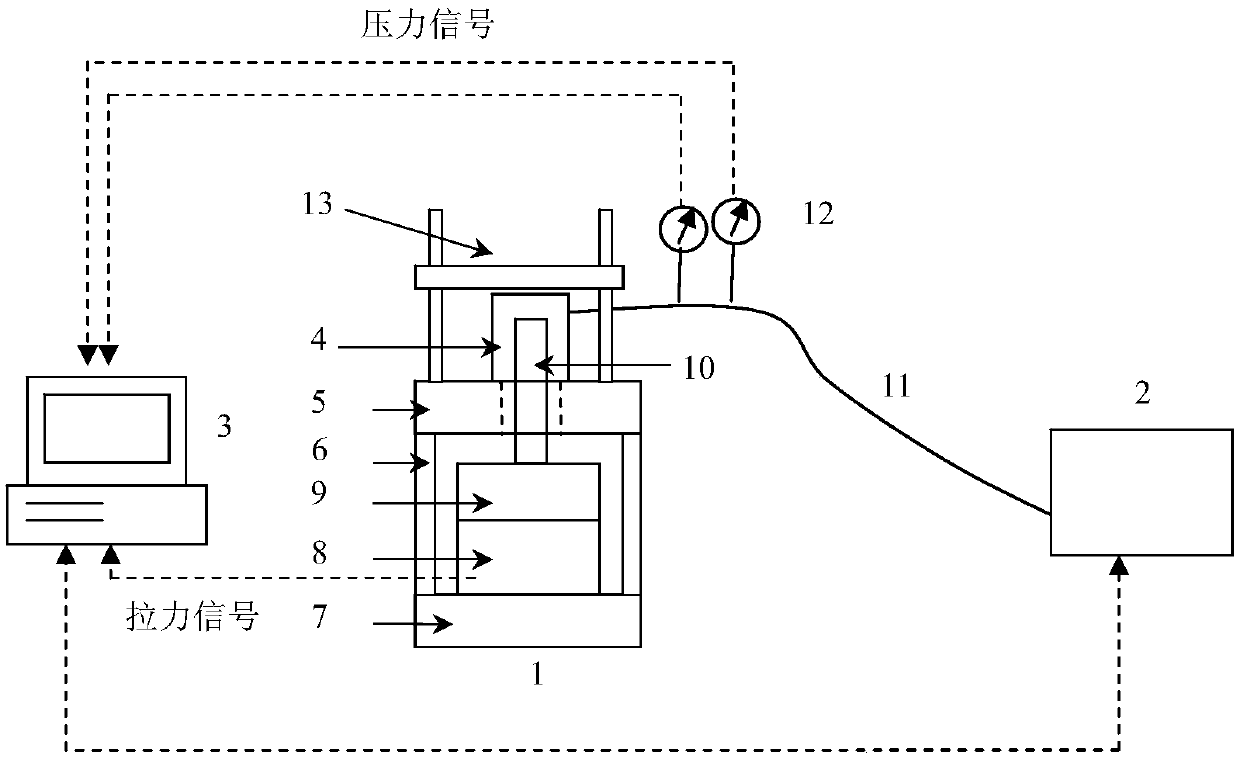

[0021] Hydraulic bolt tensioner calibrator such as figure 1 As shown, the calibrator includes a carrying device 1 , an ultra-high pressure oil source 2 , a computer and operating software 3 and a safety protection device 13 .

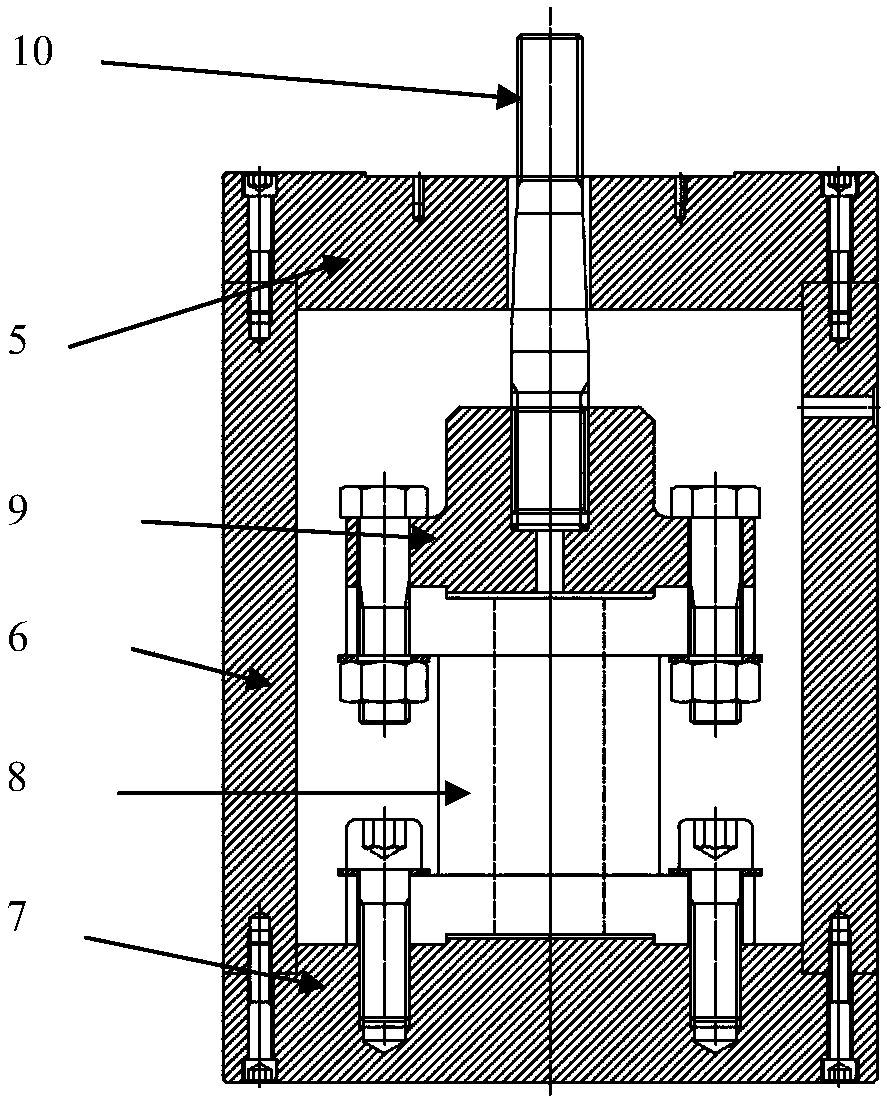

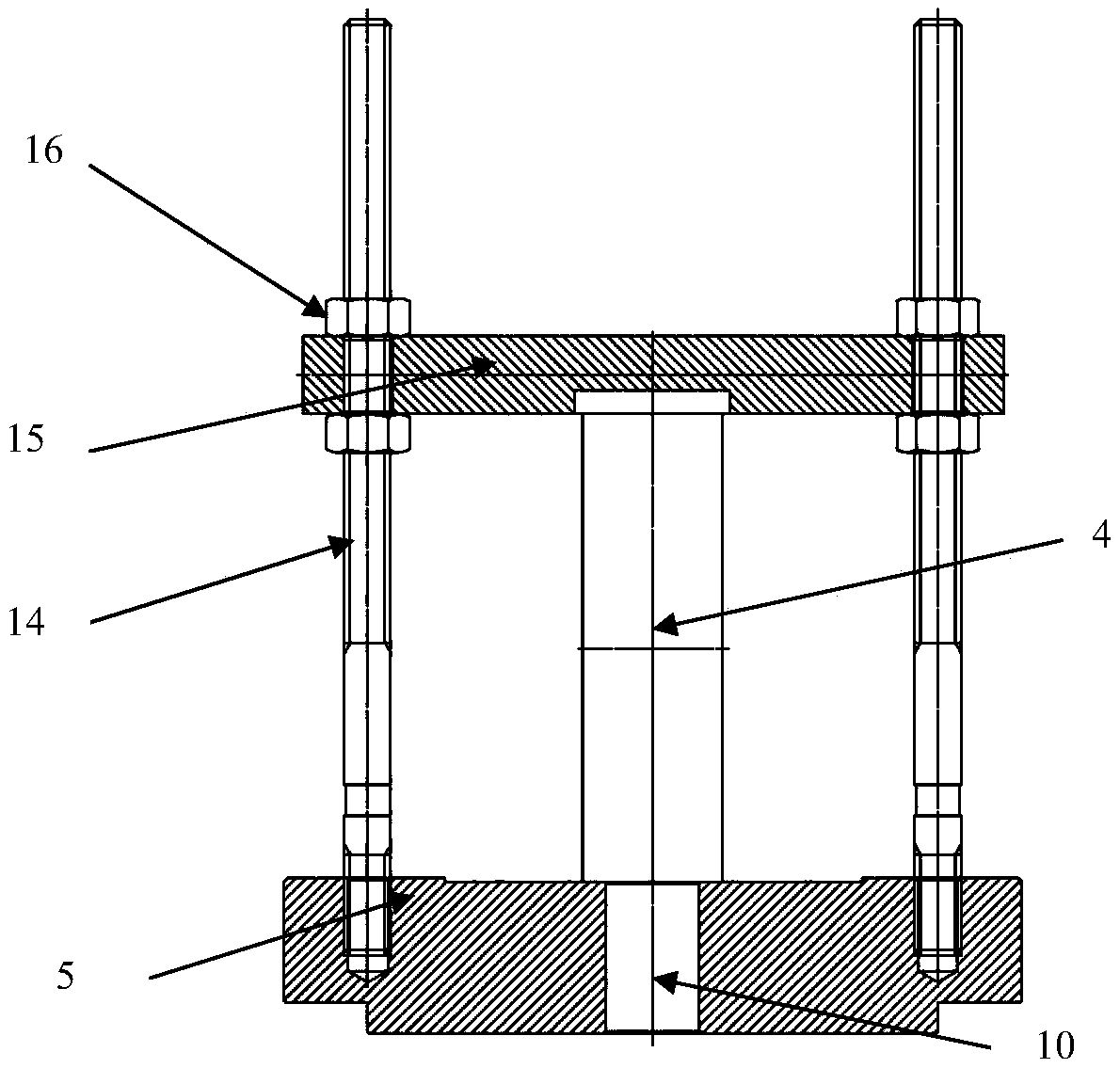

[0022] Carrying device 1 such as figure 2 As shown, the hydraulic bolt tensioner 4 is connected and installed to bear the large load tension force generated by the hydraulic bolt tensioner 4, and the tension force of the hydraulic bolt tensioner 4 is collected. The bearing device 1 is a closed internal force circulation structure, which can meet the test of the large-load hydraulic bolt tensioner 4 . The carrying device 1 includes a top cover 5 , a support 6 , a base 7 , a working force sensor 8 , a test bolt mounting support 9 , a test bolt 10 and the like. The hydraulic bolt tensioner 4 is installed above the top cover 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com