Coating device and coating method

A coating device and coating technology are applied in the field of coating device and coating method to achieve the effect of rapid operation and improved connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

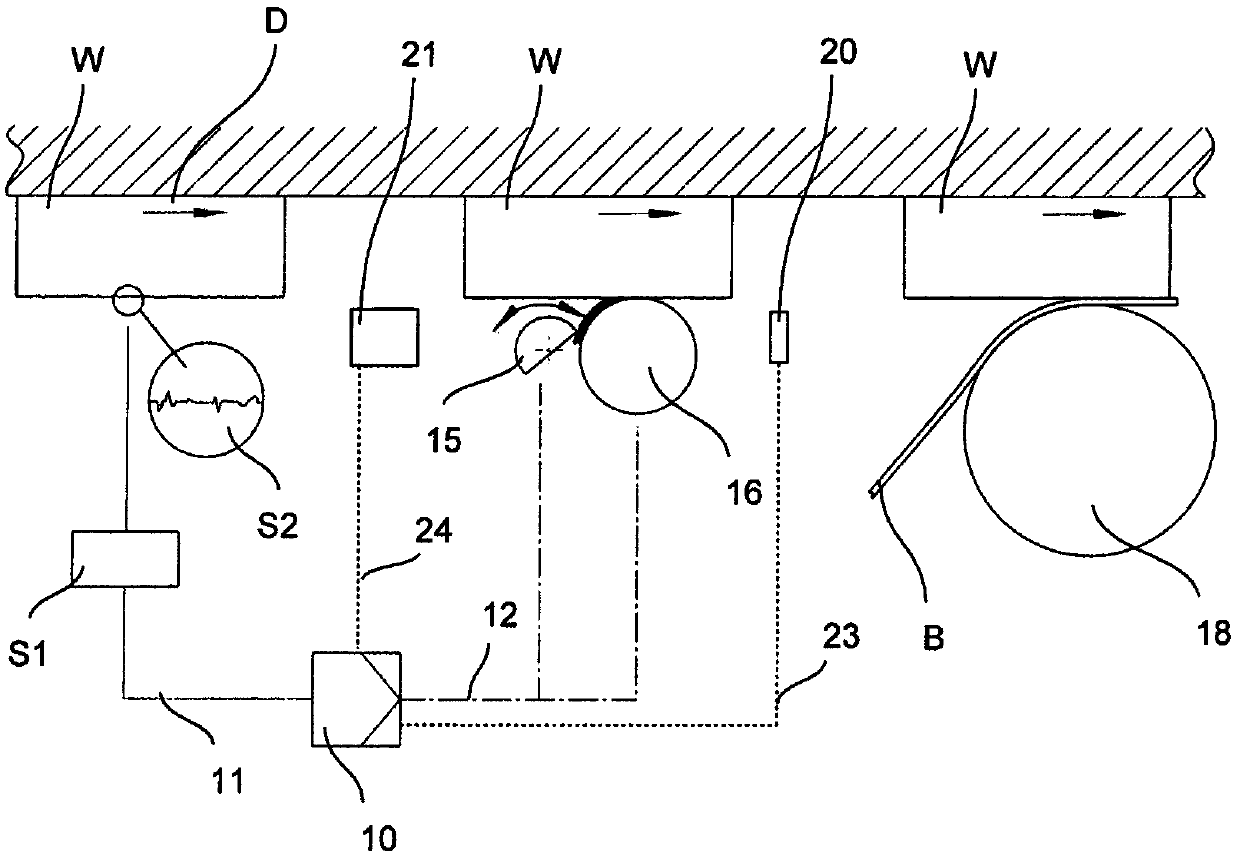

no. 1 approach 1

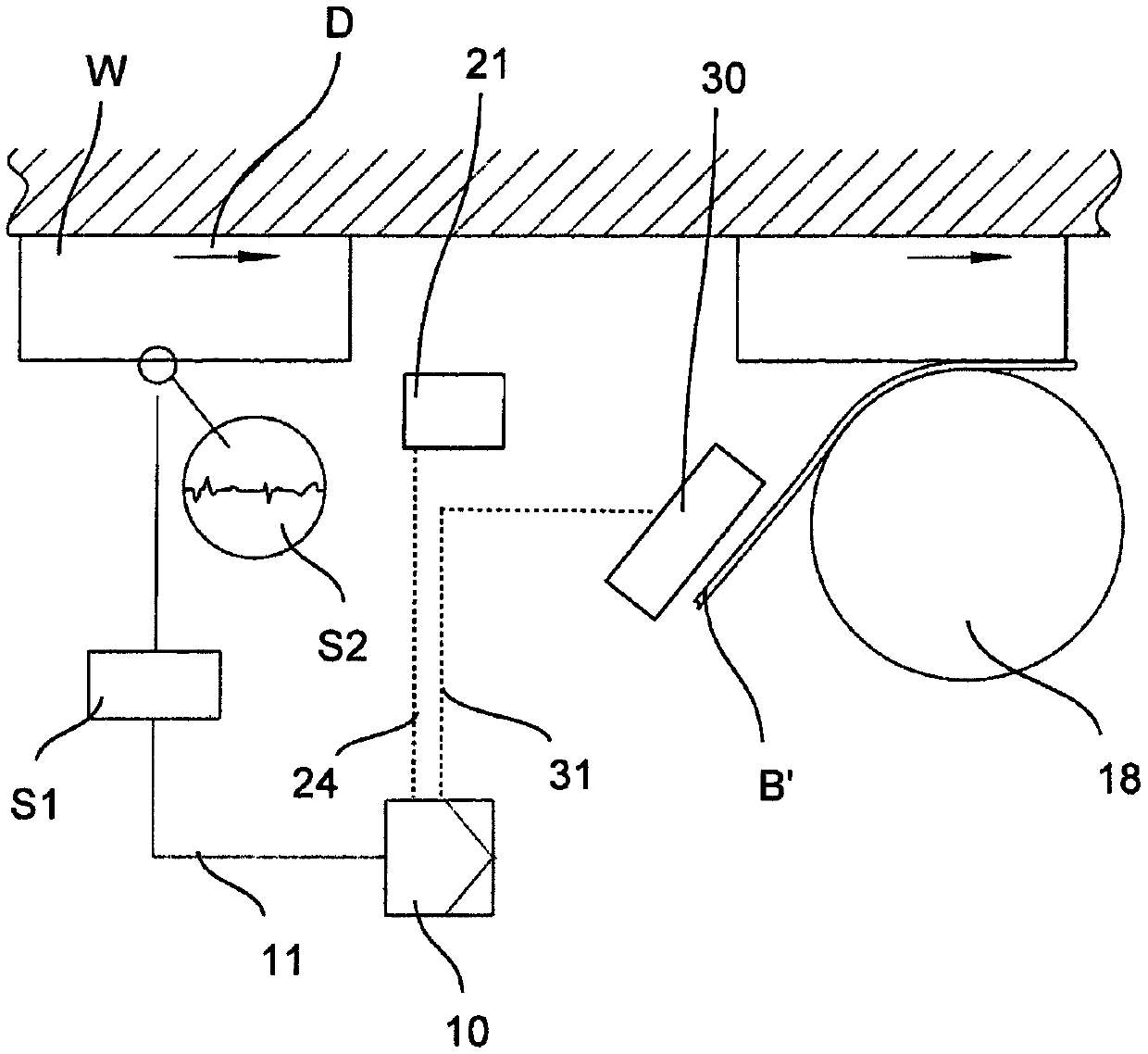

[0064] Like the first embodiment, the coating device according to the second embodiment comprises a first sensor S1 and a second sensor S2 connected to the control device 10 by a line 11 . Furthermore, a manipulation device 21 is provided which is connected to the control device 10 via a line 24 .

[0065] The second embodiment differs from the first embodiment in that instead of applying the adhesive on the workpiece, the activation of the adhesive provided on the coating material B' takes place. The coating material B' can be a coextruded coating material or a support material provided with an adhesive layer.

[0066] Thus, according to a second embodiment, an activation device 30 is provided, which is connected to the control device 10 by a line 30 . The activation device 30 is configured to activate the adhesive or adhesion-promoting layer of the coating material B', in particular to heat it.

[0067] If an elevated surface temperature on the workpiece is detected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com