Support pin of catalytic converter device with electric heating sheet

A catalytic converter and support pin technology, applied in the direction of exhaust devices, noise reduction devices, catalyst carriers, etc., can solve the problems of reduced insulation, magnesia is not resistant to leaching, short circuit, etc., and achieve the effect of improving the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

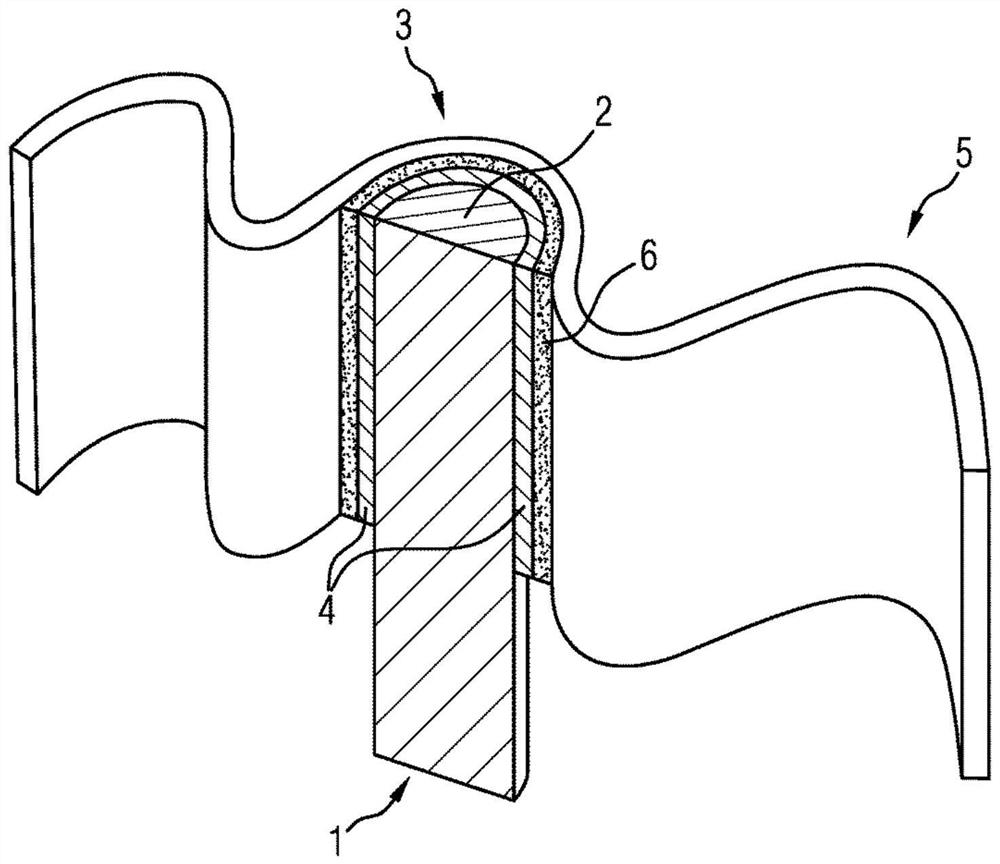

[0024] figure 1 A cross section of the support pin 1 is shown. The support pin has a ceramic core 2 . The support pin 1 has, on both ends of the support pin (but only one of the ends is shown), a thickening 3 which is formed by a coating 4 consisting of a ceramic-metal mixture.

[0025] The support pins 1 are accommodated in the honeycomb body 5 . exist figure 1 Only a part of the corrugated layer of the honeycomb body 5 is shown. Here, the support pin 1 is embedded in one of the corrugations on the front side. The corrugated layer shown and the smooth layer not shown together form the flow channels of the honeycomb body 5 .

[0026] An adhesion promoter 6 is arranged between the support pin 1 and the honeycomb body 5 for the connection between the honeycomb body 5 and the thickening 3 of the support pin 1 . The adhesion promoter 6 can be, for example, a solder which is used to solder the honeycomb body 5 to the ceramic-metal mixture 4 of the support pin 1 .

[0027] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com