Forklift feeding structure for steel mill

A forklift, feeding technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of guide wheel falling, affecting the production of hot rolling material, and achieve the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

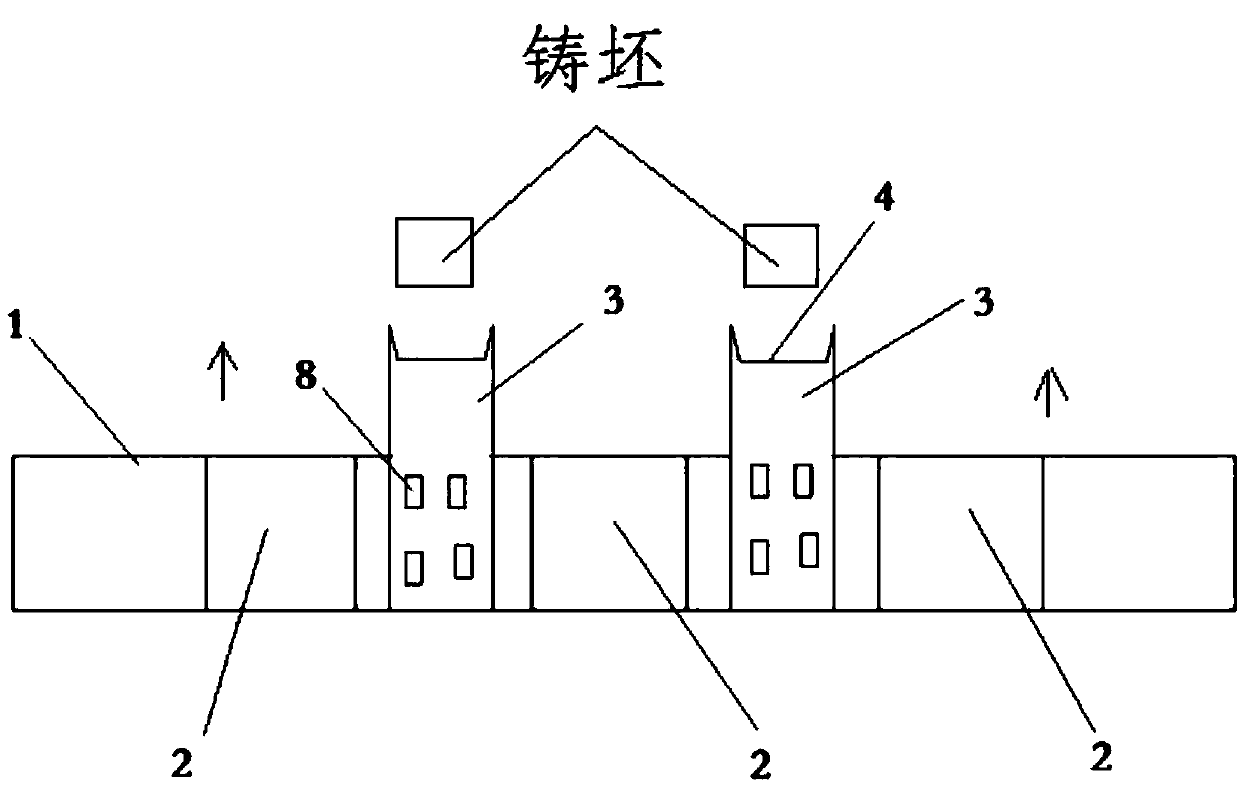

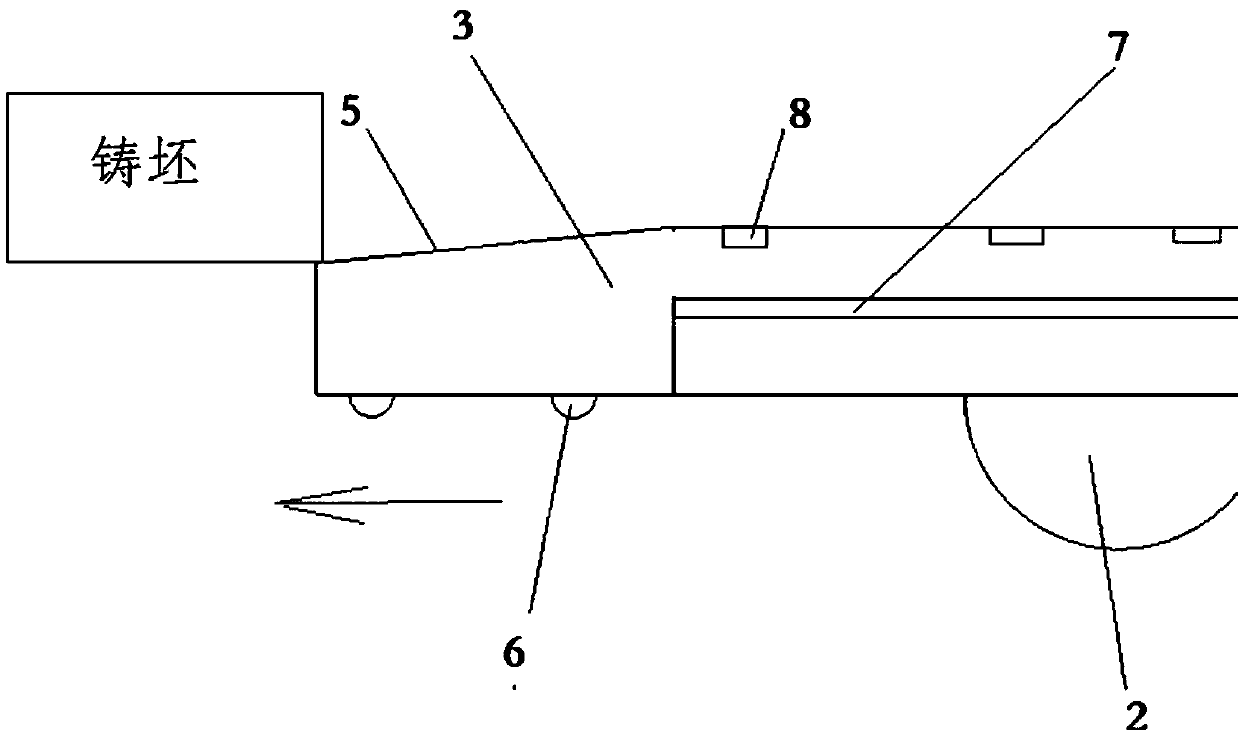

[0009] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the present invention comprises frame 1, and multiple groups of fork wheels 2 are arranged on frame 1, and guide structure is arranged between described two groups of fork wheels 2, and described guide structure comprises a support beam 3, and described support beam 3 and The unloading platform is arranged vertically; the rear end of the support beam 3 and the frame of the unloading platform are slidably set through the track 7, and multiple groups of guide wheels 8 are arranged on the upper surface of the rear end of the support beam; the front end of the support beam is a guide frame 4, and the bottom is provided with The roller 6; the guide frame is provided with a slope 5, and the height of the slope 5 is greater than the height of the fork wheel 2. The front of the guide frame is the casting slab. When the guide frame moves in the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com