Crawler chassis winch suction dredging robot

A crawler chassis and robot technology, applied in the field of robots, can solve problems such as endangering the safety of the main canal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a crawler chassis winch suction dredging robot, which can realize underwater harmless continuous movement and rapid dredging.

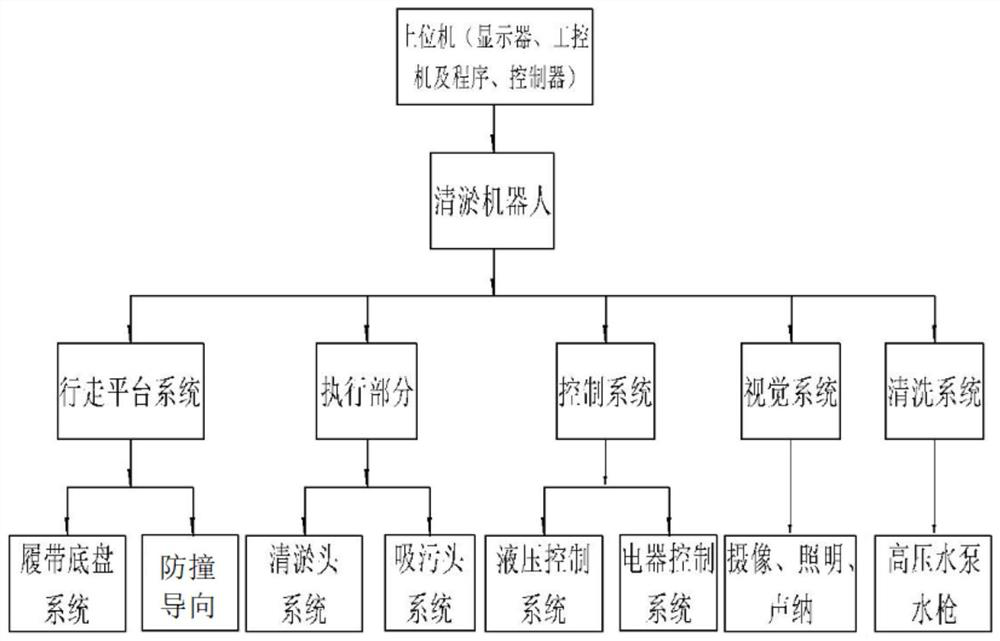

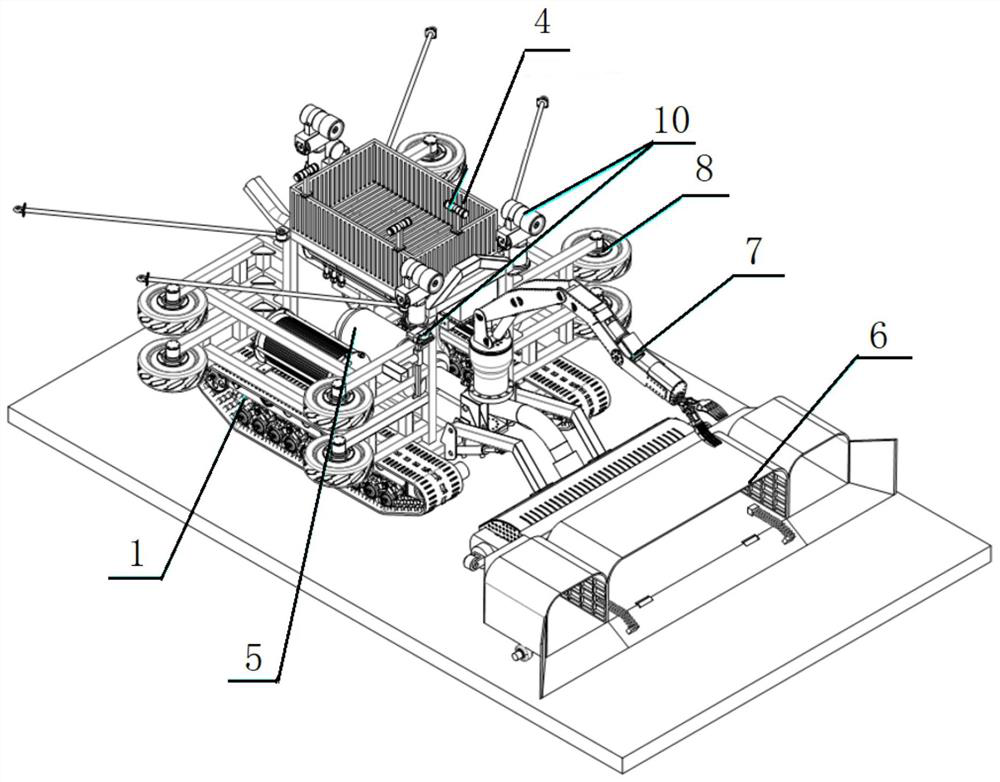

[0033] Such as figure 1 and figure 2 As shown, the dredging robot includes a platform frame 15, and a crawler chassis 1 arranged on the platform frame 15, a sludge suction mechanism 6, a dredging mechanism 7, an anti-collision guiding device, a control unit and a vision unit. Wherein the crawler chassis 1 and the anti-collision guiding device form a walking platform system, and the sludge suction mechanism 6 and the dredging mechanism 7 are the execution parts.

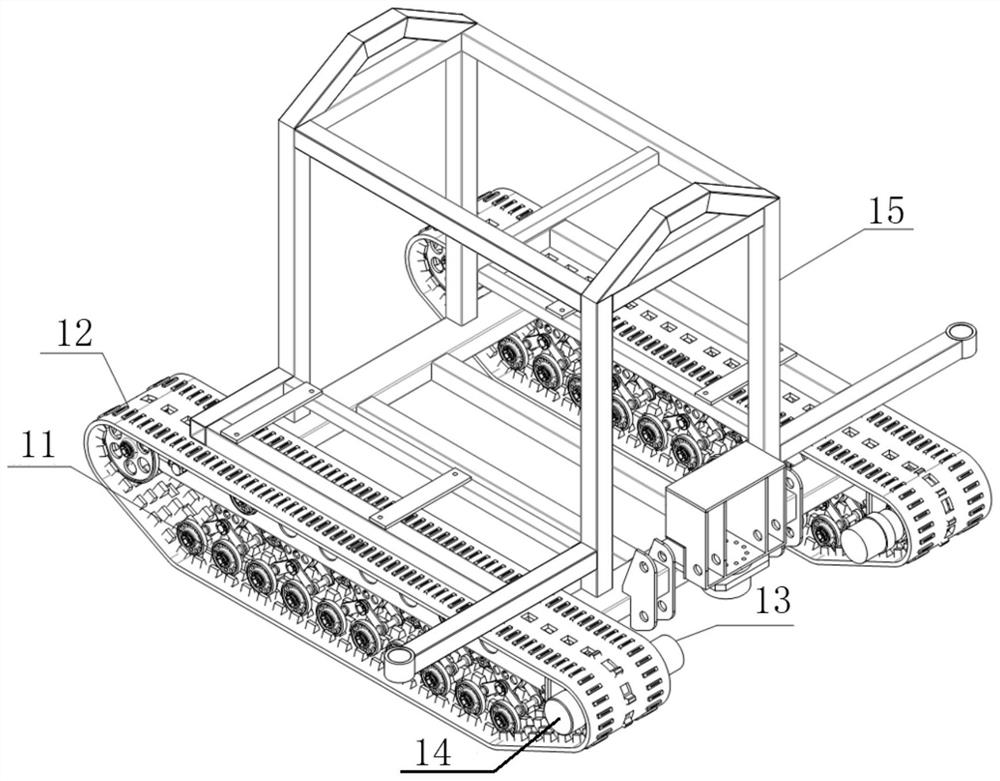

[0034] Such as image 3 As shown, the dredging robot uses a crawler chassis 1 as a walking mechanism, and the crawler chassis 1 includes: a crawler hub 11, a crawler belt 12, a motor A13 and a reducer 14; the platform frame 15 is the supporting structure of the entire robot, and the top is provided with a collection basket The basket 4 has a crawler hub 11 ...

Embodiment 2

[0048] On the basis of the above-mentioned embodiment 1, in the sludge suction mechanism 6, two extension springs 23 are arranged side by side between the middle collection cover 19 and the collection port 24, and one end of the extension spring 23 is connected to the pull spring on the inner bottom surface of the middle collection cover 19. Spring support links to each other, and the other end links to each other with the extension spring support of collection mouth 24 surfaces, and suction silt mechanism 6 is in the process of collecting silt, and collection mouth 24 is under the action of external force (through the five-axis mechanical arm 45 in the dredging mechanism in this scheme) The support plates arranged on the left and right sides of the collection port 24 apply downward force) and open, and now the extension spring 23 is in an elongated state; unclamp), the collection port 24 is closed under the action of extension spring 23, which can prevent the mud in the collec...

Embodiment 3

[0050] On the basis of the above-mentioned embodiment 1, the connection mode between the sludge suction mechanism 6 and the platform frame is changed, and the sludge suction mechanism 6 is connected with the platform frame through a telescopic arm, specifically: one end of the telescopic arm is connected to the suction sludge mechanism through a rotating oil cylinder. The support at the top of the mechanism 6 is hinged, and the other end is pinned to the mounting seat, and the mounting seat is fixed on the platform frame through the rotating base, which is used to drive the telescopic arm to swing left and right within a set angle range. At the same time, a supporting oil cylinder is set under the telescopic arm, and the cylinder end of the supporting oil cylinder is fixed on the mounting seat, and the piston rod end is connected with the telescopic arm. Floating can achieve the effect of vibration reduction; during maintenance, the sludge suction mechanism is supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com