Dredging system of sewage pipeline with large-pipe diameter

A technology for sewage pipelines and large diameter pipes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of not having too much dirt, endangering the lives of workers, and being expensive, and achieve the process of dredging. Simple, good dredging effect, small size of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

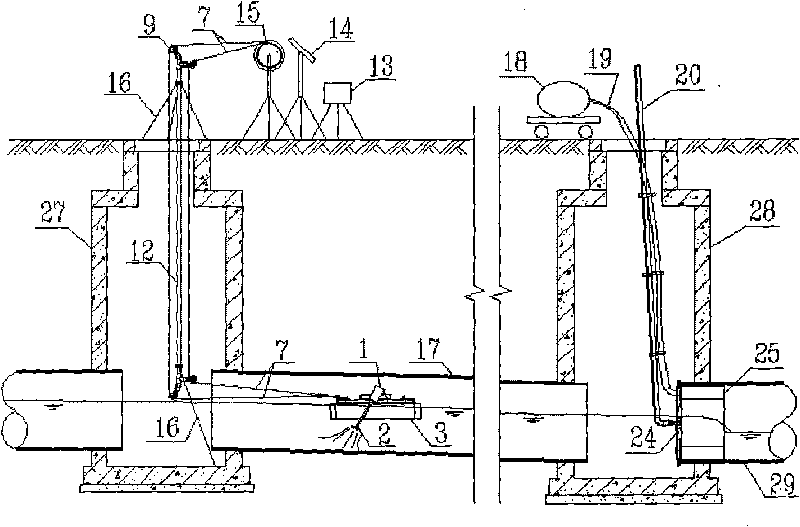

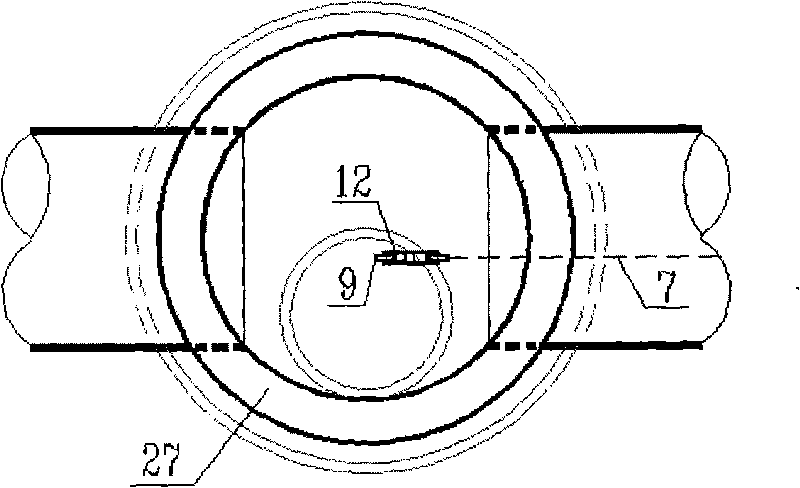

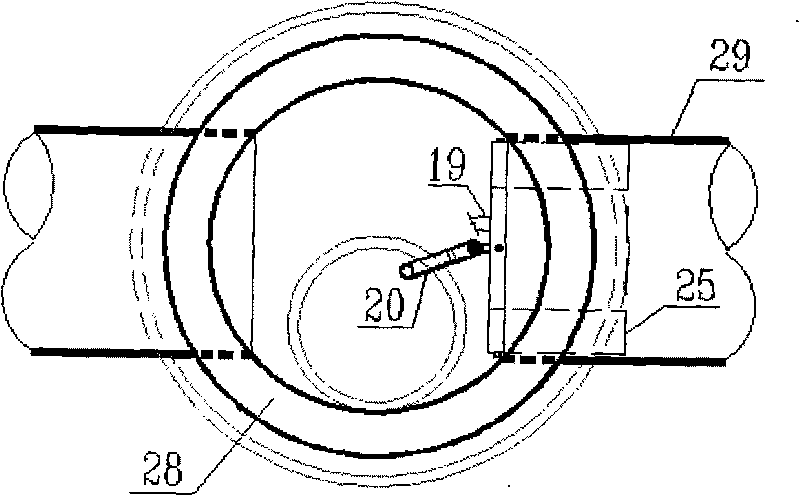

[0046] see figure 1 , figure 2 and image 3 , The dredging system includes an underground dredging boat, an above-ground operating system for the dredging boat, an inflatable rubber gate and an above-ground inflation and deflation device for the inflatable rubber gate.

[0047] 1. Underground dredging boat, combined with figure 1 and Figure 4's Figure 4A , Figure 4B and Figure 4C : It is formed by connecting two pontoons 3 through four connecting angle steels 4, and the four connecting angle steels are fixed on the pontoon brackets of the two pontoon boxes. A high-speed waterproof motor 1, a stirring propeller 2 and four cameras 6 are installed on the dredging boat.

[0048] The shape of the buoyancy tank 3 is long. The high-speed waterproof motor 1 and the stirring propeller 2 are installed in the middle of the two buoyancy tanks 3. The direction of the agitation propeller 2 is obliquely downward, that is, the connecting rod of the propeller extends downward into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com