The adjustment method of the backlash of the gear transmission and the calculation method of the grinding amount of the tooth thickness

A gear transmission and adjustment method technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem that the backlash of paired gears does not meet the assembly requirements, and achieves high accuracy, simple calculation process, and reduction The effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

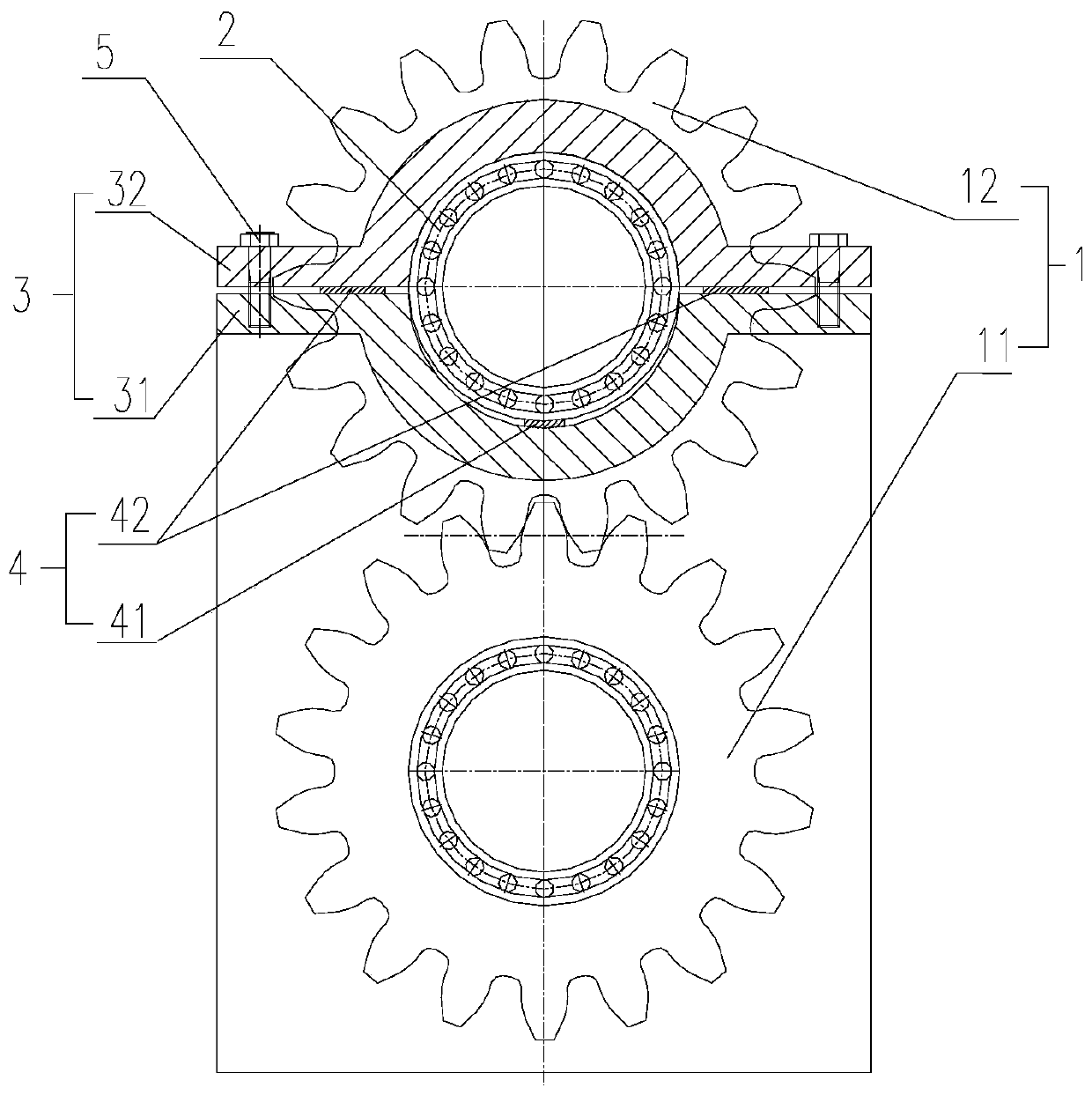

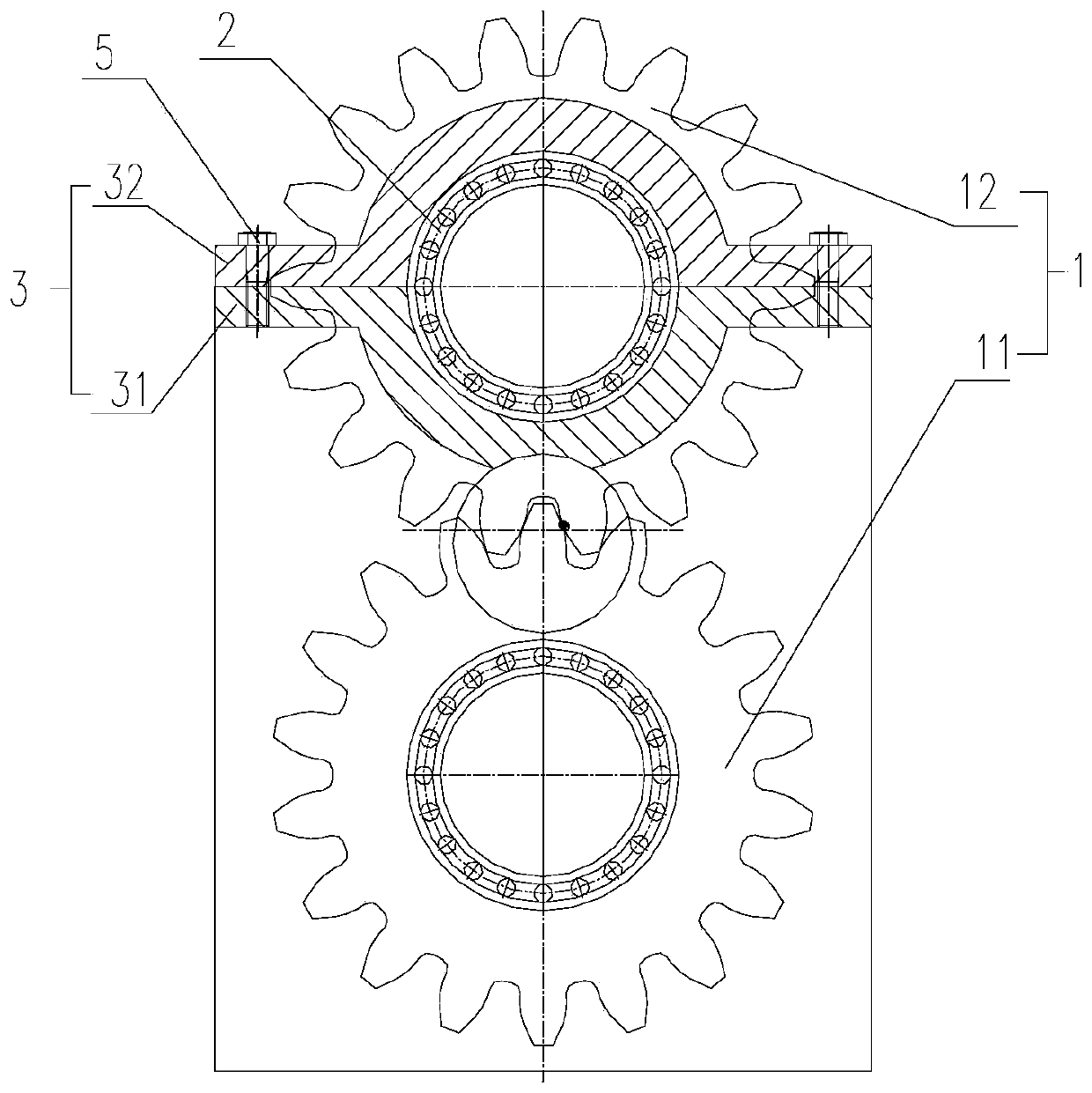

[0032] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-3 As shown, this embodiment provides a method for adjusting the backlash of a gear transmission, including the following steps:

[0034] S1. Provide a set of matching gears 1, at least one gear is reserved for grinding allowance;

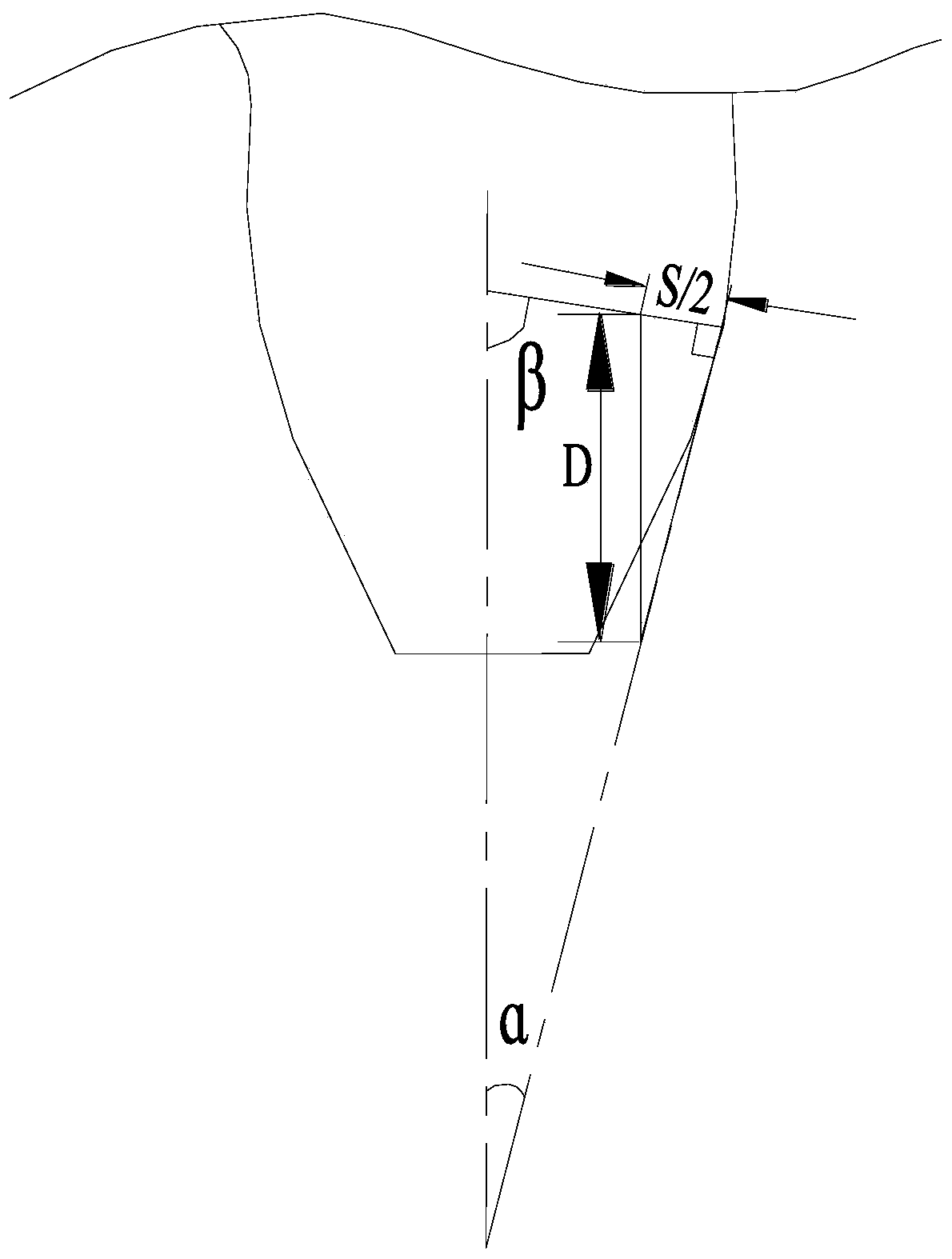

[0035] S2. Adjust the assembly clearance of the mating gear 1 so that the assembly clearance of the mating gear 1 meets the side clearance requirement, and then calculate the displacement D of the mating gear 1 relative to the standard position;

[0036] S3. Calculate the tooth thickness grinding amount S of the gear according to the displacement amount D and grind the gear.

[0037] In step S1, the two gears in the paired gear 1 can both reserve a grinding allowance, and after calculating the tooth thickness grinding amount S, both gears are ground, and the tooth thickness grinding amount of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com