Multi-channel rotating joint

A rotary joint, multi-channel technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, passing element, etc., can solve the problems of large heat production, reduce the maximum speed of the rotary joint, reduce the service life, etc., to prolong the service life , simple structure, small number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

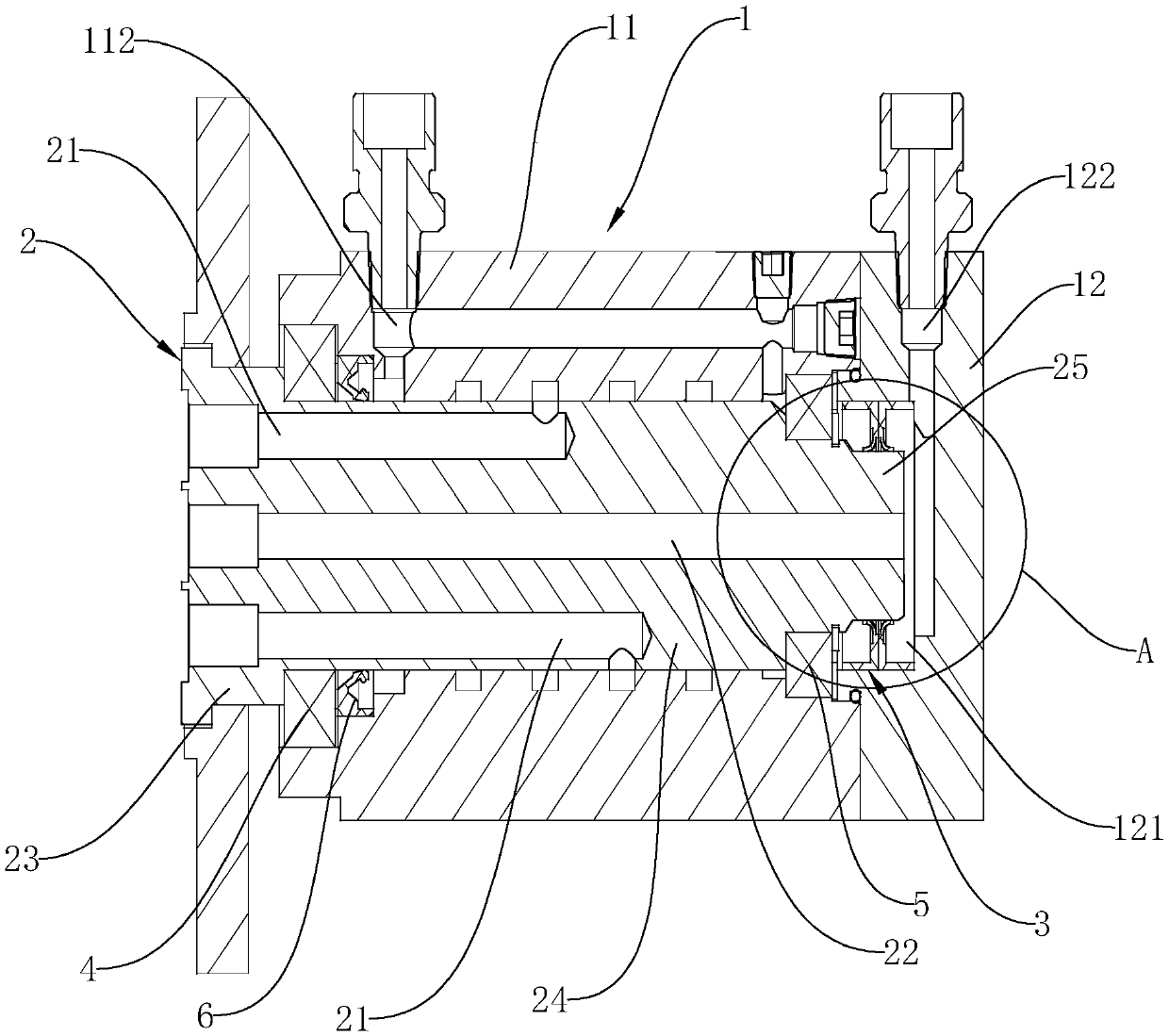

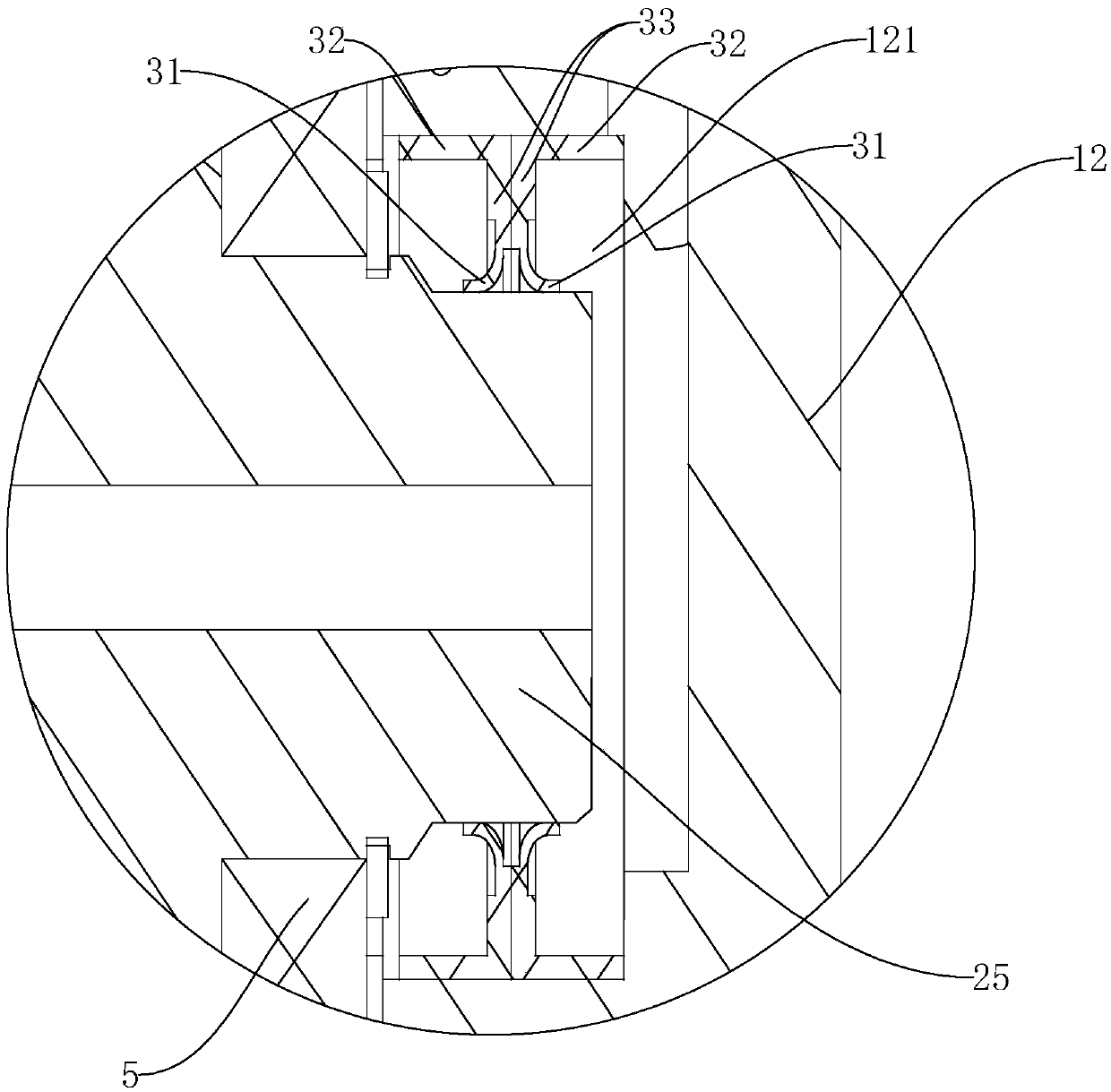

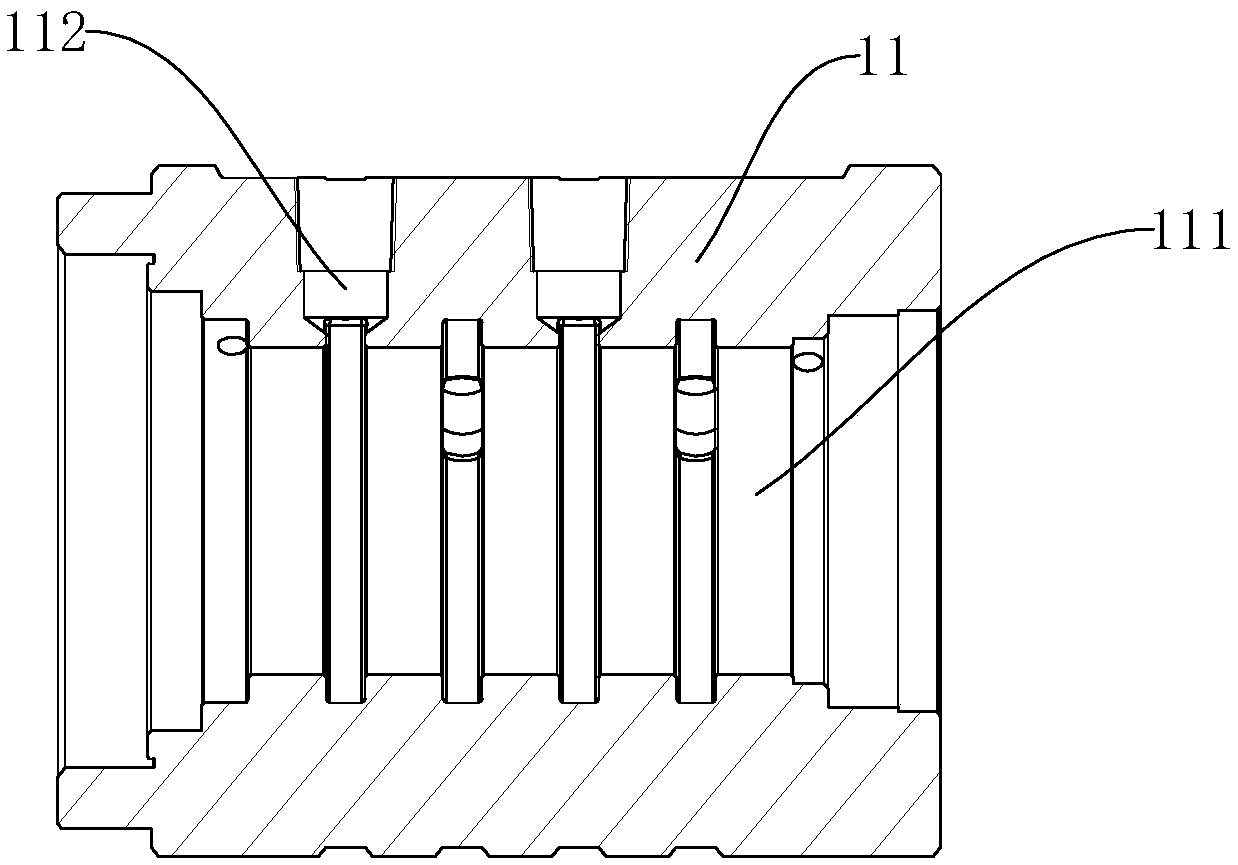

[0019] Such as Figure 1 to Figure 4 As shown, a multi-channel rotary joint includes an outer casing 1 and a rotating shaft 2. The outer casing 1 includes an outer sleeve 11 and a back cover 12 sealed and installed at the rear end of the outer sleeve 11. The outer sleeve 11 is provided with a front and rear through An installation chamber 111 for installing the rotating shaft 2, the rotating shaft 2 is rotatably arranged in the installation chamber 111 and the front end of the rotating shaft 2 protrudes from the installation chamber 111;

[0020] A plurality of first conveying holes 21 are arranged in the rotating shaft 2, and the first conveying holes 21 are blind holes arranged along the direction of the central axis of the rotating shaft 2 from the front end surface of the rotating shaft 2, and are arranged on the side wall of the outer sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com