A gas injection engine

An engine and gas technology, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problems of high manufacturing cost, large axial size of the engine, and difficult impeller design and manufacturing, and achieve high gas supply pressure and mechanical Efficiency and compressor working efficiency, the effect of improving mechanical efficiency and compressor working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

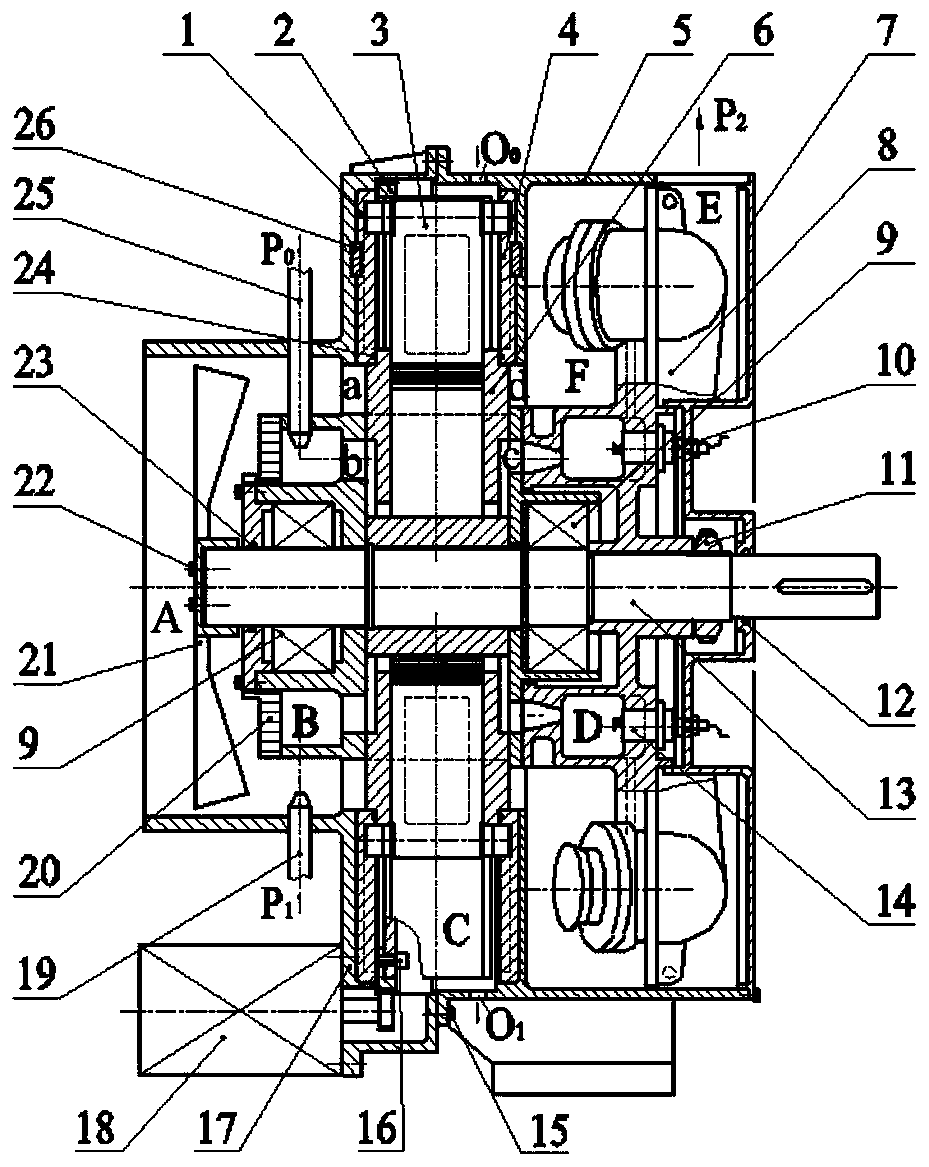

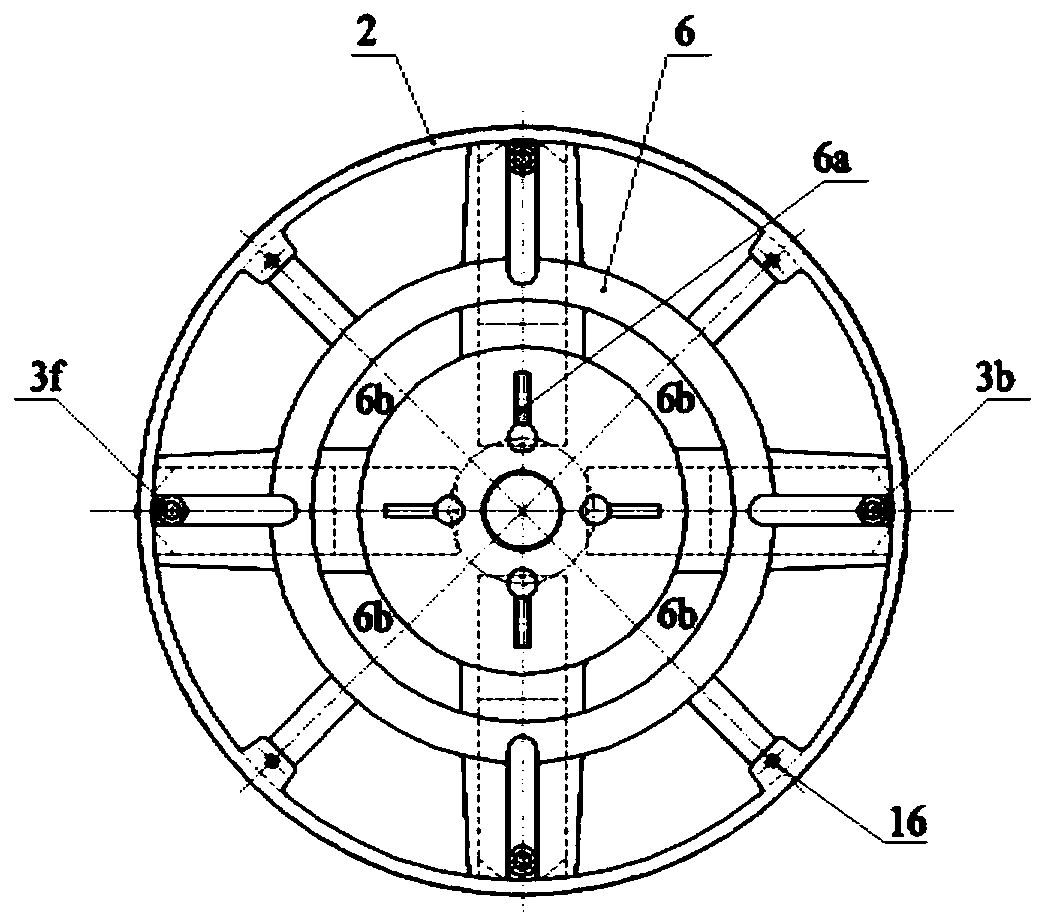

[0037] The present invention provides a gas injection engine, which comprises a left cam 1, a plunger assembly 3, a right cam 4, a rotating cylinder 6, a large ring gear 2, a central shaft 13, a left box 17, a left end cover 20, and an impeller 21 , Starter motor 18, inner nozzle 25, outer nozzle 19, right casing 5, right end cap 7, conductive ring 10, turntable 8, spark plug 14, guide tube 29, spool 28 and spring 27.

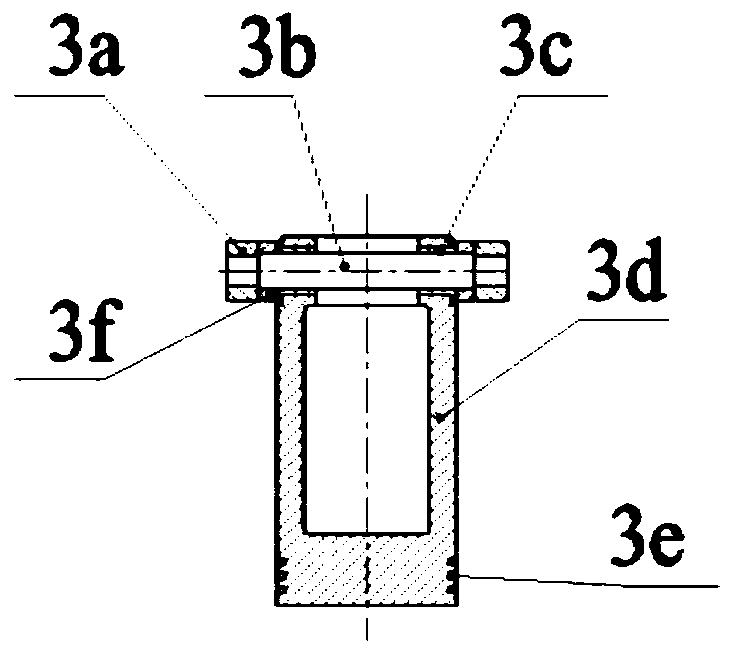

[0038] figure 2 It is an assembly diagram of the plunger assembly in the engine of the present invention. One end of the plunger 3d is hinged with the short shaft 3b through the bearing bush 3c, and the other end is equipped with a sealing ring 3e. The bushing 3f is vacantly sleeved on the short shaft 3b. The roller 3a is in interference connection with the shaft end of the short shaft 3b. Two bushings 3f, two bearing bushes 3c and two rollers 3a are arranged symmetrically on both sides of the axis of the plunger 3d, forming the radial movement unit of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com