Conductor contact connector

A technology of connectors and conductors, applied in the field of conductor contact connectors, can solve the problems of easy loosening of screws, complicated heat welding methods, inconvenient flexible connection and separation, etc., and achieve the effect of strengthening wires and stable and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

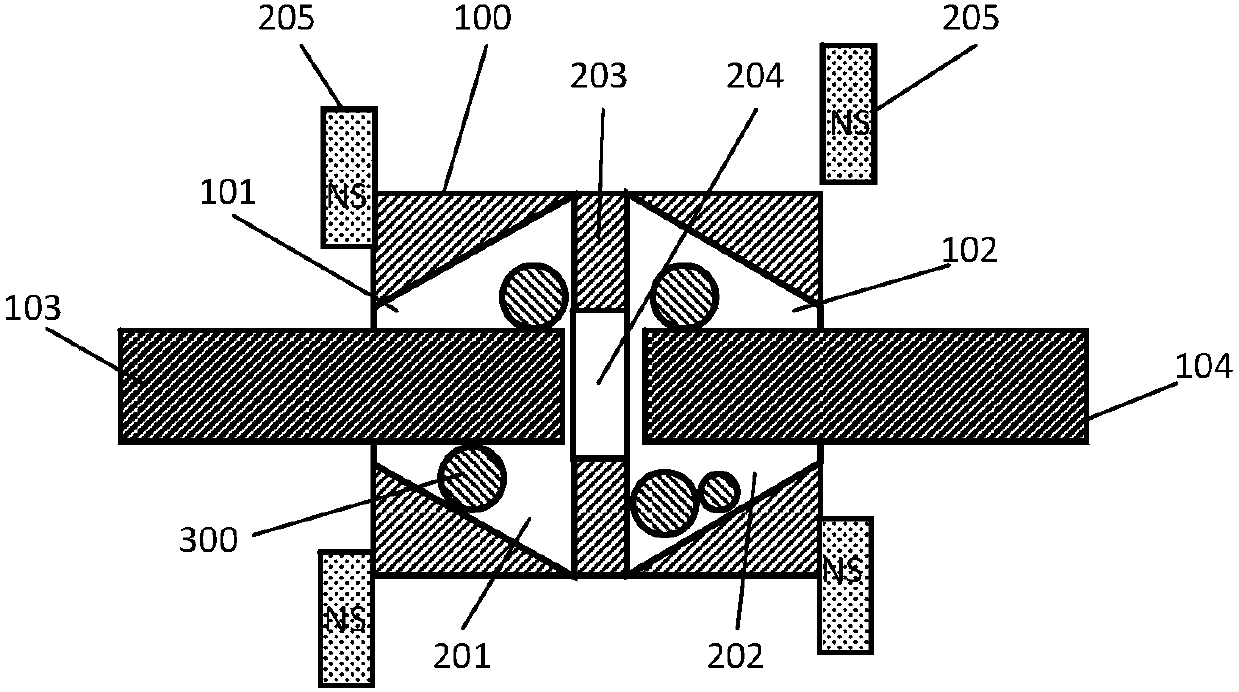

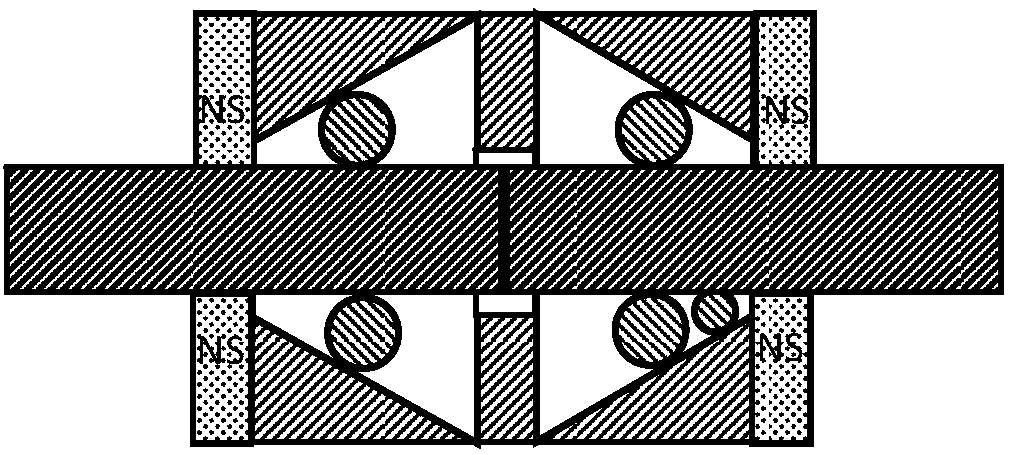

[0054] Such as figure 1 , figure 2 Shown:

[0055] The controllable stopper 100 includes a first channel 201 and a second channel 202; a moving contact body 300 is arranged in the first channel 201 and the second channel 202; Narrows, forming wide and narrow mouths;

[0056] The controllable stopper 100 also includes a docking plate 203; a docking hole 204 is provided on the docking plate 203; the docking hole 204 communicates with the first channel 201 and the second channel 202;

[0057] The controllable stopper 100 also includes a magnetic driving mechanism 205 ; under the magnetic field generated by the magnetic driving mechanism 205 , the moving contact body 300 can be driven to the narrow opening for the locking.

[0058] The wide mouth is closer to the docking hole 204 than the narrow mouth.

[0059] Both the first conductor 103 and the second conductor 104 are wires.

[0060] Specifically, the moving contact body 300 may be a sphere, an ellipsoid or a polyhedron...

no. 2 example

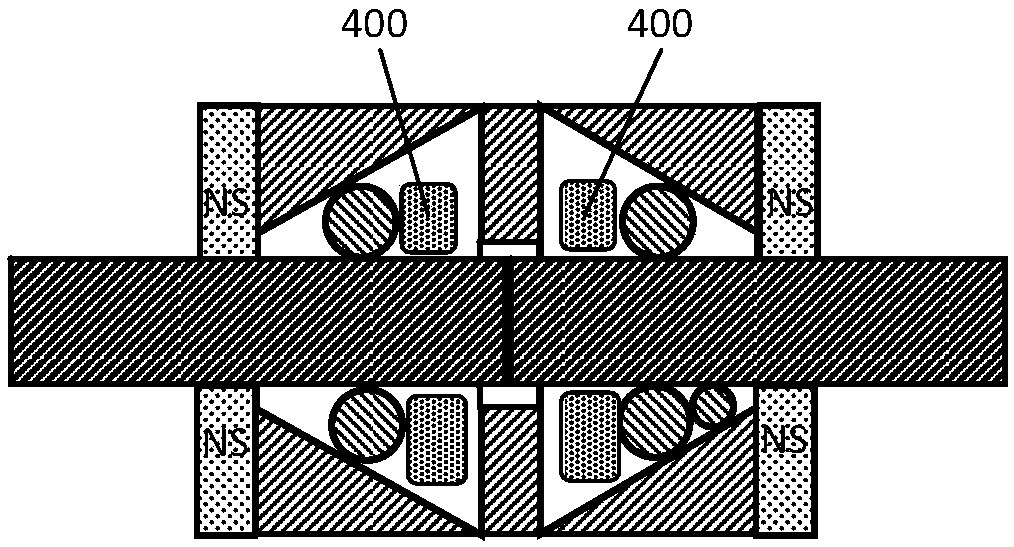

[0062] The second embodiment is a preferred example of the first embodiment. Such as image 3 Shown:

[0063] Both the first channel 201 and the second channel 202 are provided with a movement stopper 400;

[0064] Under the magnetic field generated by the magnetic driving mechanism 205, the moving stopper 400 is driven, and the moving contact body 300 is pushed to the narrow opening by the moving stopper 400 to perform the locking.

[0065] Specifically, the moving stopper 400 is a magnet capable of being affected by a magnetic field, and the moving contact body 300 is a non-magnetic body not affected by a magnetic field, such as a ceramic body or copper. In both the first passage 201 and the second passage 202 , the movement blocking body 400 is closer to the wide opening than the movement contact body 300 . The moving stop 400 is located outside the moving contact body 300 , or the moving stop 400 is embedded in the moving contact body 300 .

no. 3 example

[0067] The third embodiment is a modified example of the first embodiment. Such as Figure 4 , Figure 5 Shown:

[0068] The narrow mouth is closer to the docking hole 204 than the wide mouth; or, the wide mouth is closer to the docking hole 204 than the narrow mouth;

[0069] The moving contact body 300 is a direction-abnormal body, and the moving contact body 300 in the first channel 201 and the second channel 202 can both rotate to perform the locking.

[0070] Orientation heteromorphs have different scales in different directions, such as ellipsoids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com