Solid door machining paint spraying device with automatic overturning function

A technology of automatic flipping and solid wood doors, applied in the direction of spraying devices, etc., can solve the problems of insufficient environmental protection, inconvenient operation, and physical hazards of workers, and achieve the effects of high processing efficiency, large cleaning range and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

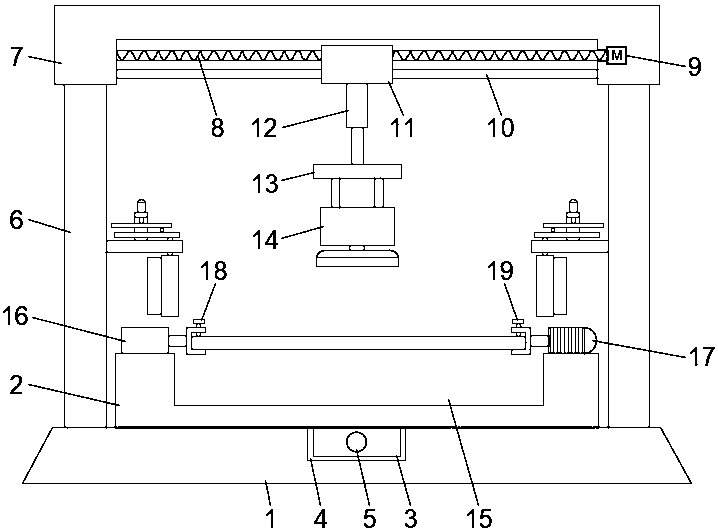

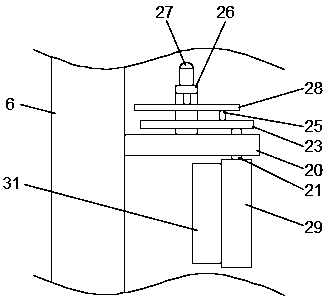

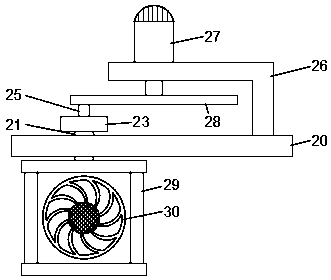

[0022] refer to Figure 1-5 , a paint spraying device with an automatic turning function for solid wood door processing, comprising a base 1, a paint spraying platform 2 is arranged on the upper end of the base 1, a slider 3 is fixedly connected to the bottom of the paint spraying platform 2, and the surface of the base 1 is provided with a slider 3. The first chute 4, and the slider 3 is located inside the first chute 4 and is slidably connected with the first chute 4. The inside of the first chute 4 is also provided with a first slide rail that is used in conjunction with the slider 3, so that the painting station 2 and the slider 3 are more stable when sliding along the first chute 4, the first chute 4 is internally connected with the first threaded rod 5, and the slider 3 is threaded on the first threaded rod 5, the first chute The first motor is fixedly installed on the side wall of one end of 4, and one end of the first threaded rod 5 is fixedly connected with the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com