Agricultural soil and fertilizer mixing crushing device

A technology of mixing, crushing and soil, applied in the field of agricultural machinery, can solve the problems of increasing root cell respiration, reducing root air permeability, uneven fertilizer throwing, etc., and achieves the effects of improving work efficiency, improving practicability, and increasing practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

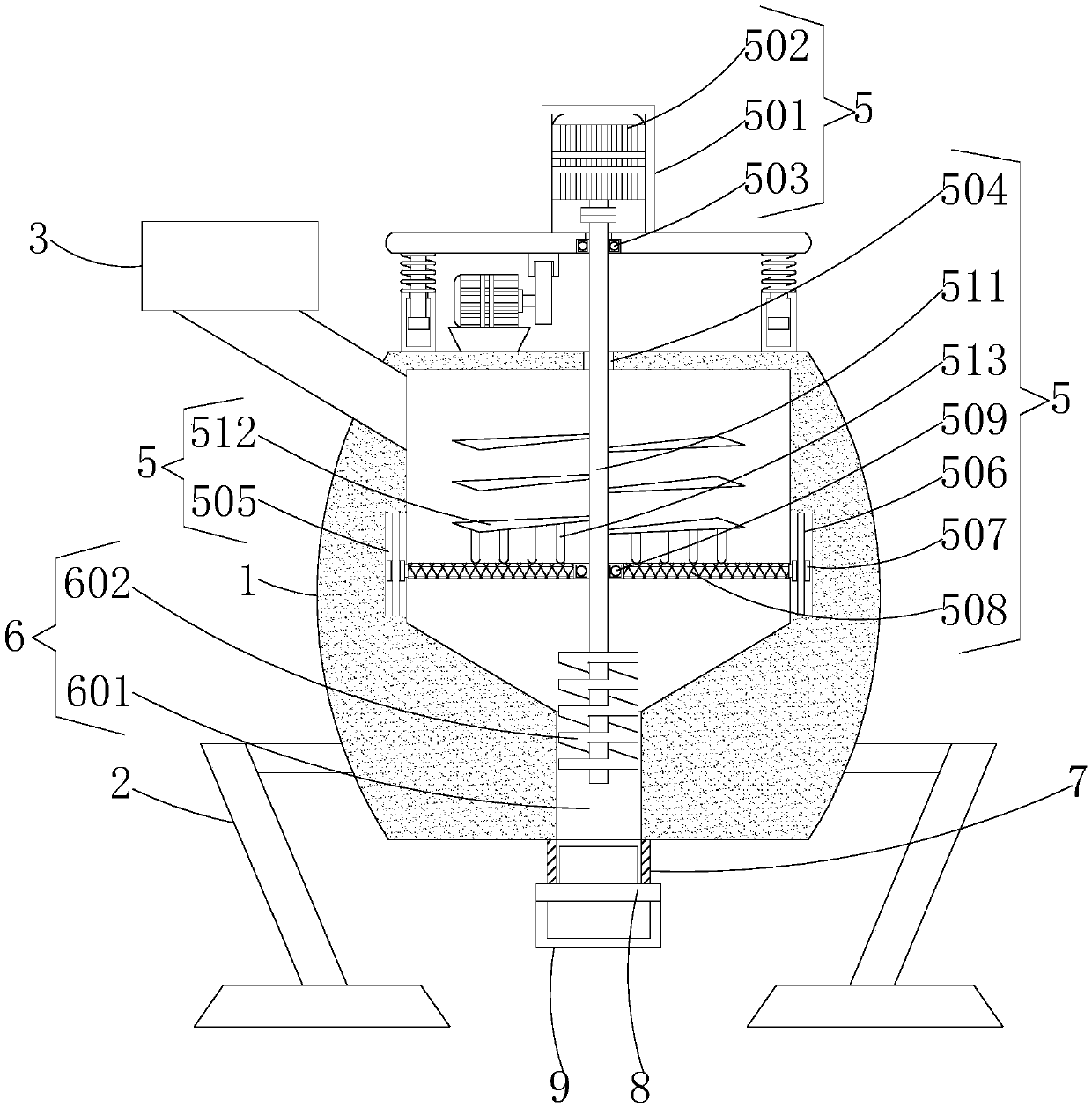

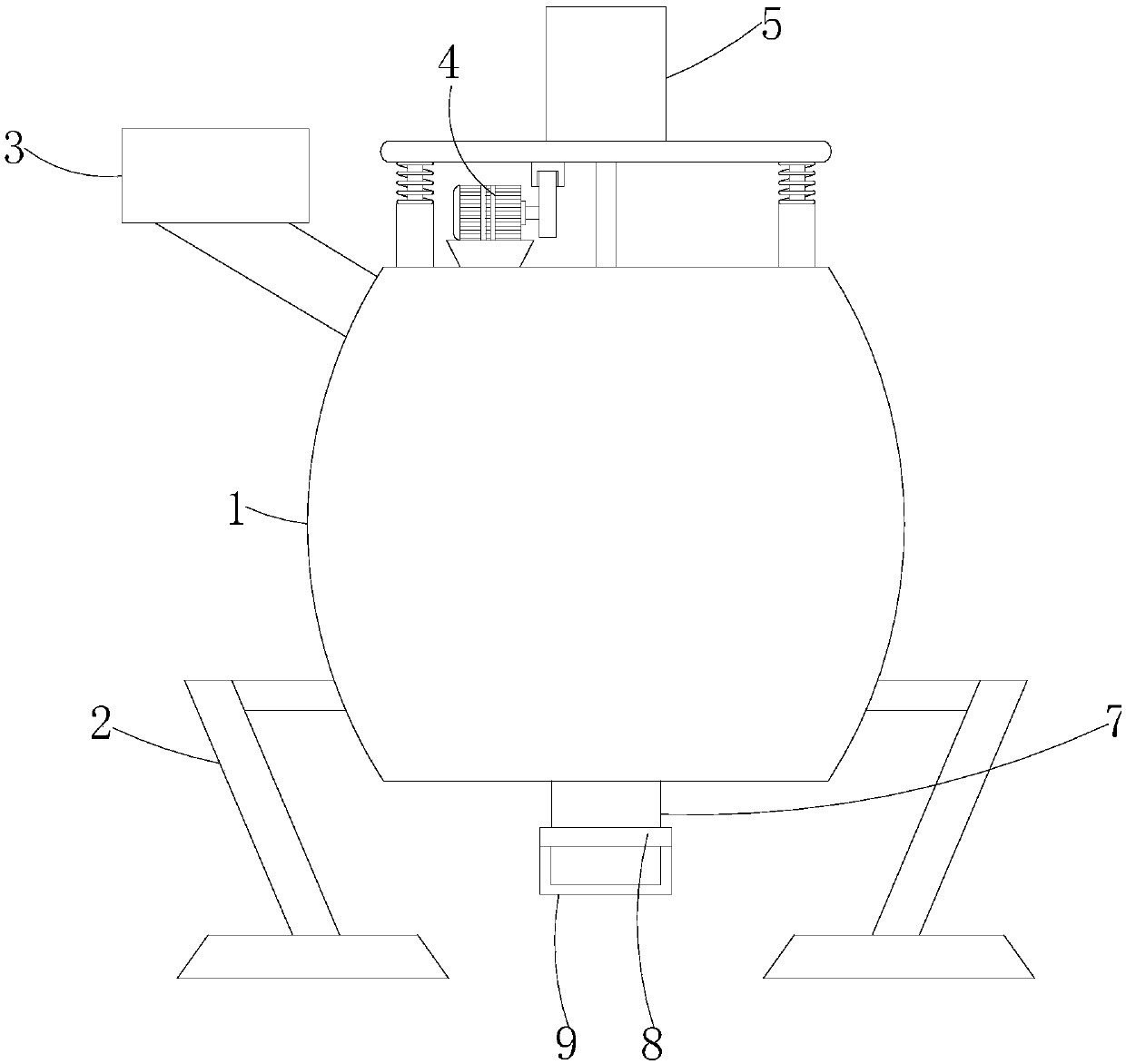

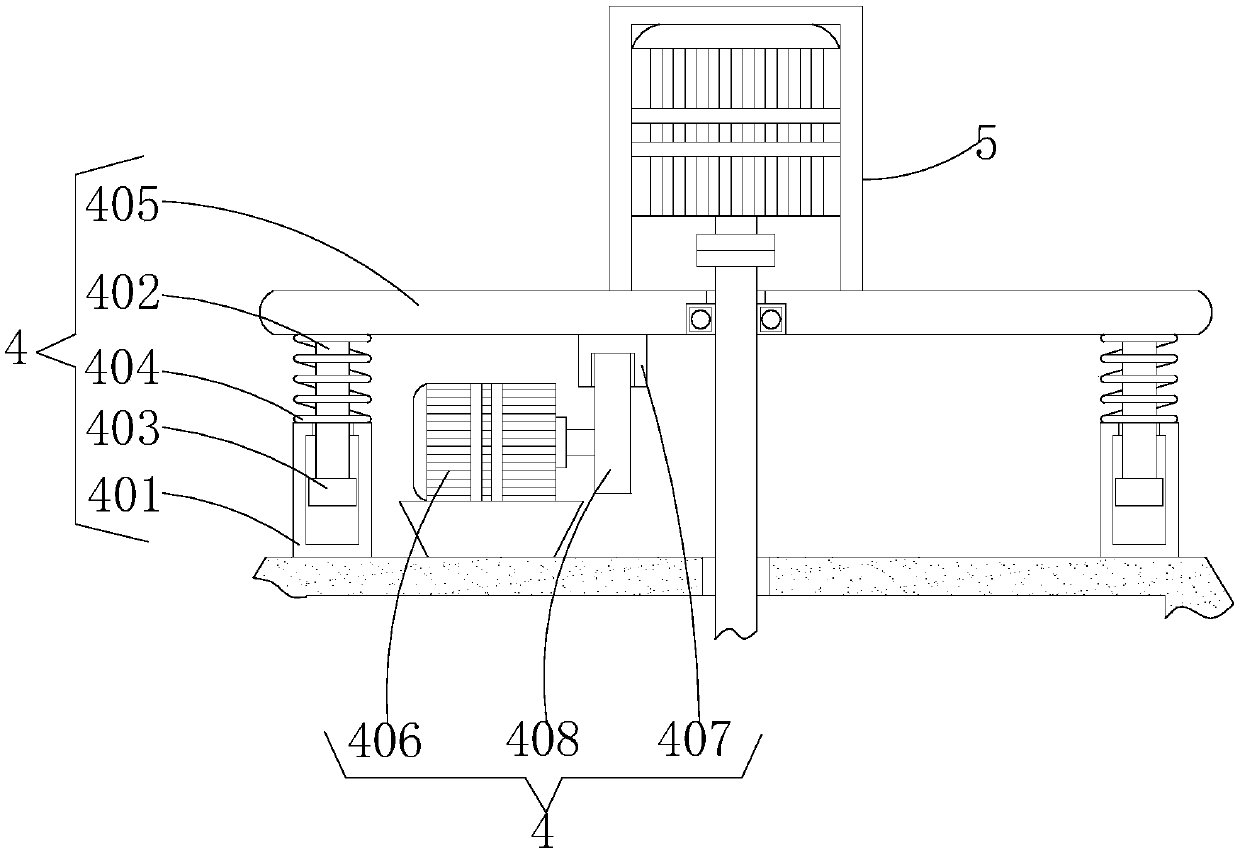

[0023] see Figure 1-3 , the present invention provides a technical solution: an agricultural soil and fertilizer mixing and crushing device, including a barrel body 1, a support leg 2, a feed bin 3, a lifting mechanism 4, a crushing mechanism 5, a conveying mechanism 6, a discharge pipe 7, Sealing cover 8, the tops of two supporting legs 2 are respectively fixedly connected with the bottom of the two sides of the barrel body 1, the total number of supporting legs 2 is four, and the outer surface of the four supporting legs 2 is ring-shaped with the outer surface of the bottom end of the barrel body 1 Array distribution, the right end of the feed bin 3 is inlaid on the top of the left side of the barrel body 1, the bottom end of the lifting mechanism 4 is fixedly connected with both ends of the top surface of the barrel body 1, the top of the crushing mechanism 5 is connected to the top surface of the lifting mechanism 4 Fixedly connected, the conveying mechanism 6 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com