Coupling Z axis rotating device

A rotating device and Z-axis technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of light-seeking deflection angle accuracy, full runout of the end face of optical devices and coaxiality that cannot meet the requirements of coupling light-seeking and welding Requirements and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

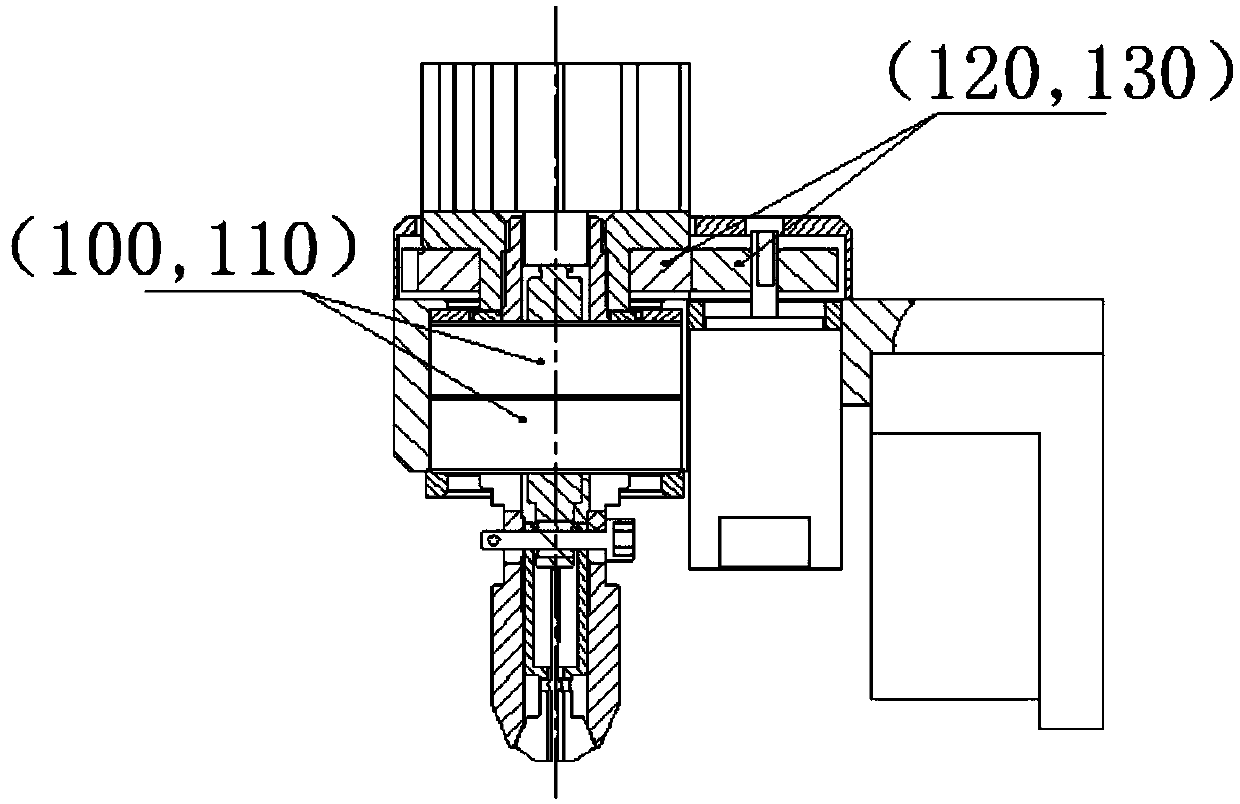

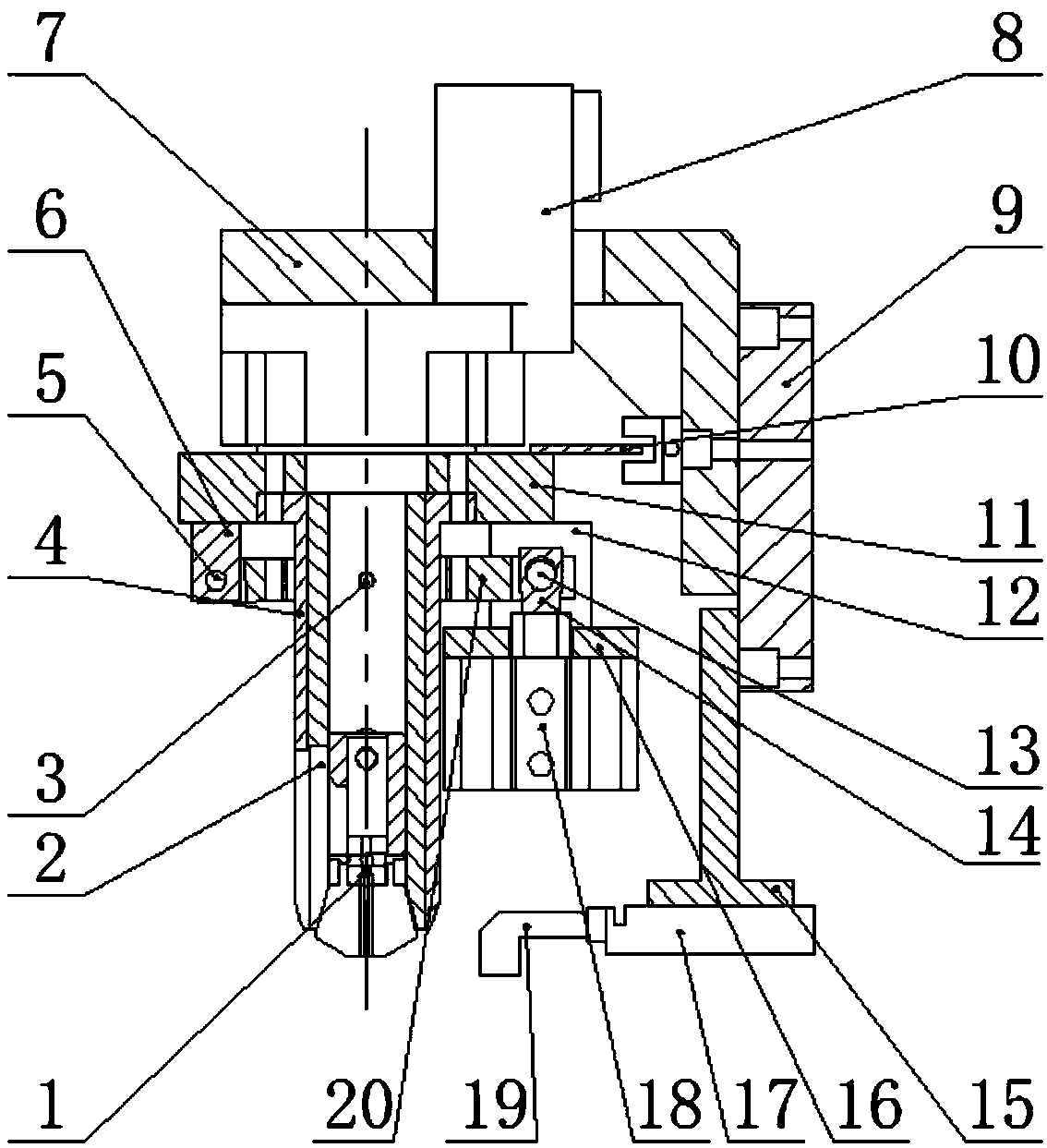

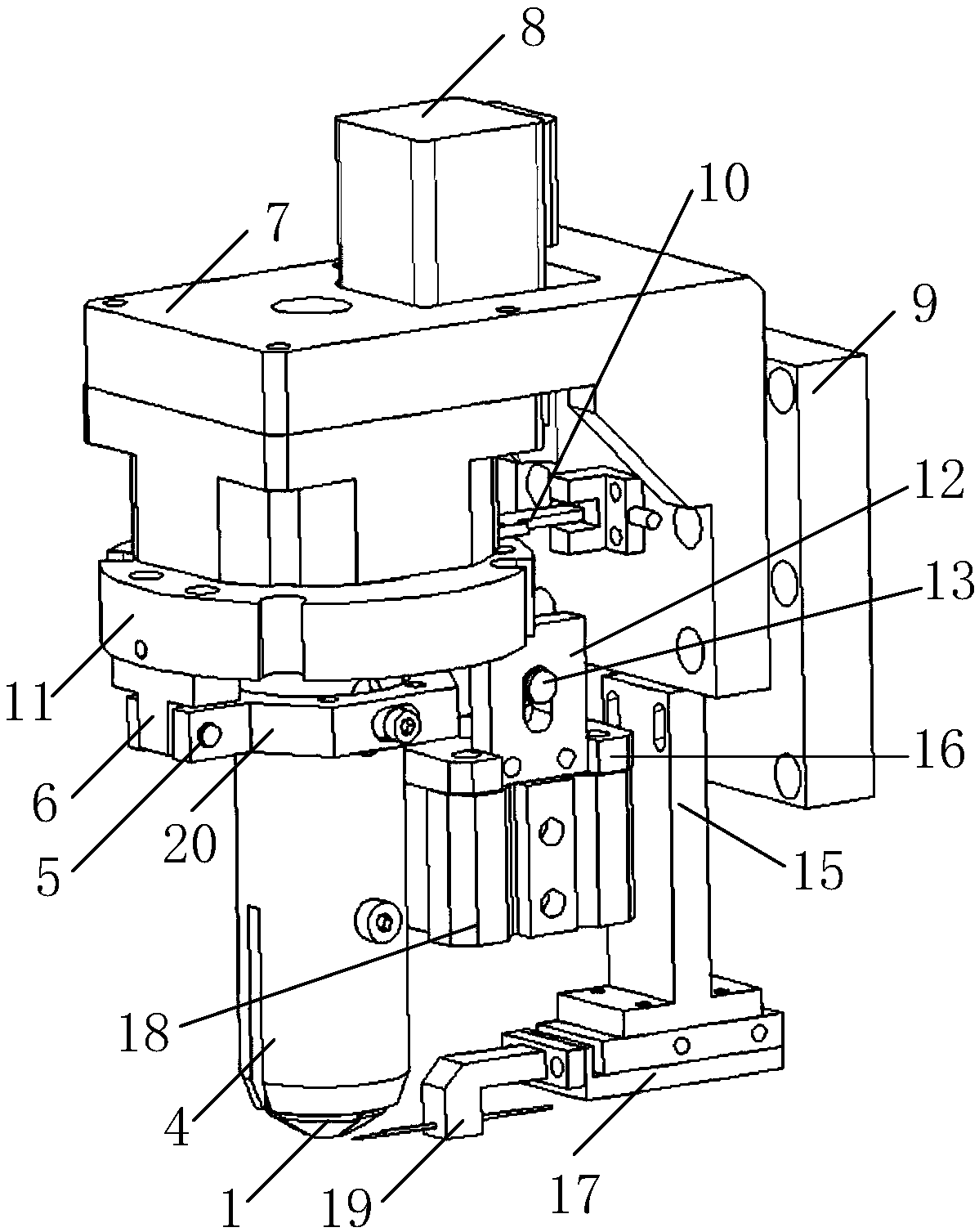

[0045] Embodiment 1 of the present invention provides a coupling Z-axis rotation device, such as Figure 2 to Figure 8 As shown, it includes a rotating part, a locking part, and a clamping part; the clamping part is arranged on the rotating part, and the locking part is arranged on the rotating part; the rotating part is used to rotate the The locking part and the clamping part; the clamping part is used to clamp the optical device, and the clamping part includes an upper locking mouth 1 and an upper chuck fixing sleeve 4, and the upper locking mouth 1 is provided with an elastic fiber The insert 1-2, the end face of the elastic fiber insert 1-2 is used to contact the end face of the optical device; the upper chuck inner sleeve 2 of the locking part is embedded in the upper chuck fixing sleeve 4 and The upper locking mouths 1 can move up and down, and the upper chuck inner sleeve 2 is used to lock the upper locking mouths 1 when going down.

[0046] The coupling Z-axis rotati...

Embodiment 2

[0051] Embodiment 2 of the present invention provides a coupling Z-axis rotation device, such as Figure 2 to Figure 8 As shown, it includes a rotating part, a locking part, and a clamping part; the clamping part is arranged on the rotating part, and the locking part is arranged on the rotating part; the rotating part is used to rotate the The locking part and the clamping part; the clamping part is used to clamp the optical device, and the clamping part includes an upper locking mouth 1 and an upper chuck fixing sleeve 4, and the upper locking mouth 1 is provided with an elastic fiber The insert 1-2, the end face of the elastic fiber insert 1-2 is used to contact the end face of the optical device; the upper chuck inner sleeve 2 of the locking part is embedded in the upper chuck fixing sleeve 4 and The upper locking mouth 1 can move up and down, and the second light hole 4-1 is used to lock the upper locking mouth 1 when the inner sleeve 2 of the upper chuck is going down.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com