Trail management tray

A pallet and trace technology, applied in the field of trace management pallets, can solve the problems of low willingness of individuals to return according to the system, complex working environment, chaotic storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

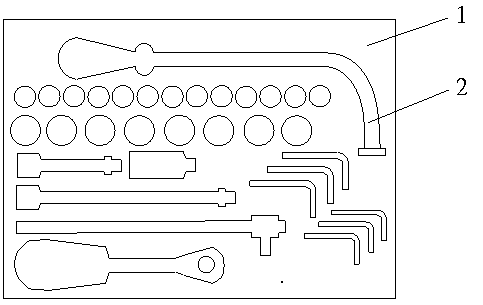

[0019] see figure 1 , a trace management tray includes: a tray body, the tray body is composed of an upper polymer material and a lower polymer material, the colors of the upper polymer material and the lower polymer material are different, and the tray body has Several three-dimensional card slots for storing parts, components, and tools. The arrangement of the three-dimensional card slots is to arrange the space in the order of disassembly and installation of parts and components; arranged. The thickness of the upper polymer material is 0.5-40mm, and the thickness of the lower polymer material is greater than that of parts, components and tools. , the shape and size of the three-dimensional card slot are the same as those of the parts, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com