Pulling type cover tire anti-skid hub

An anti-skid wheel and pull-type technology, which is applied in anti-skid devices, tire parts, transportation and packaging, etc., can solve the problems of easy entanglement of anti-skid chains, inconvenient use and carrying, and influence on later use, so as to achieve disassembly and installation Simple and convenient, low replacement cost, simple and convenient replacement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

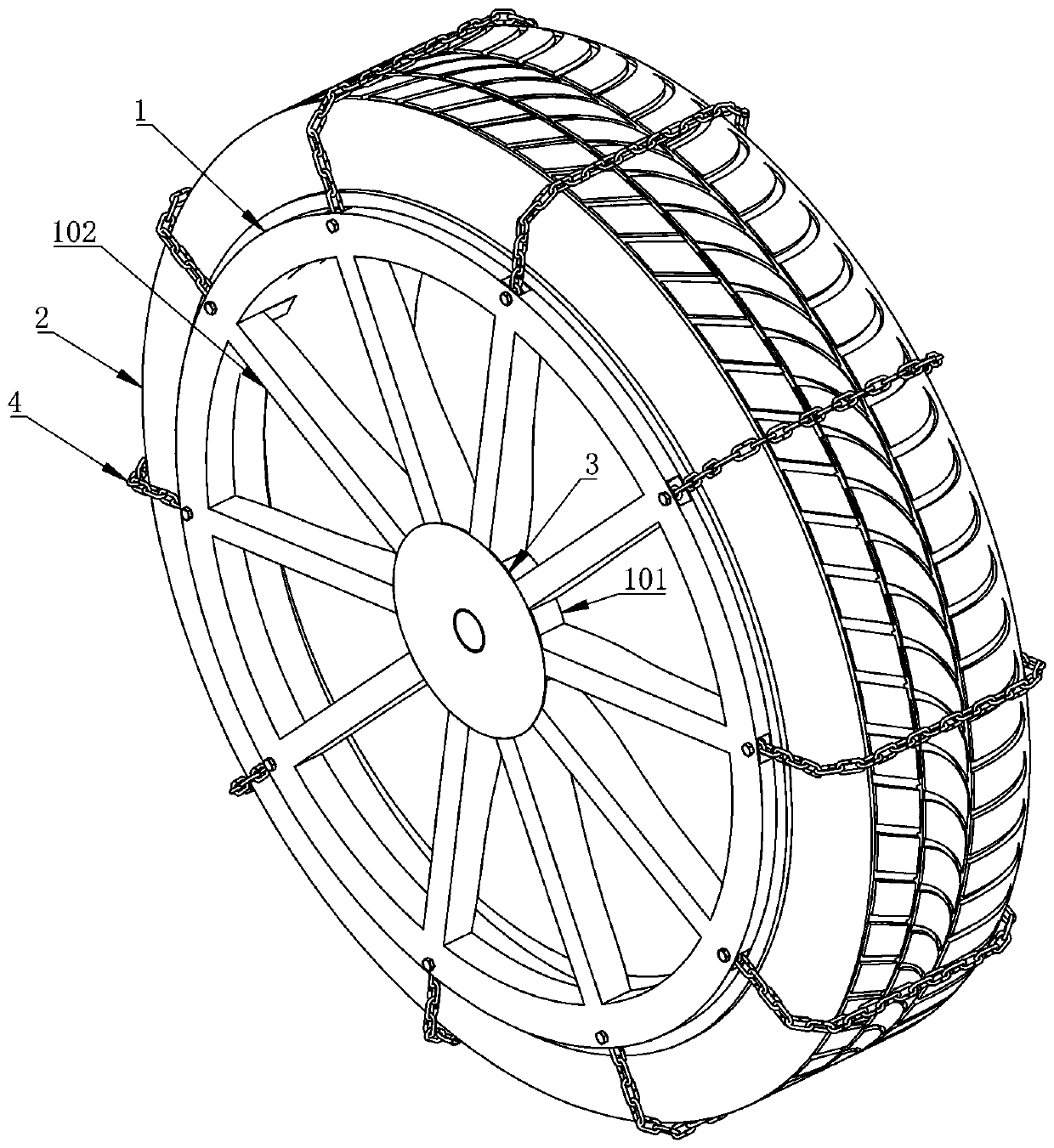

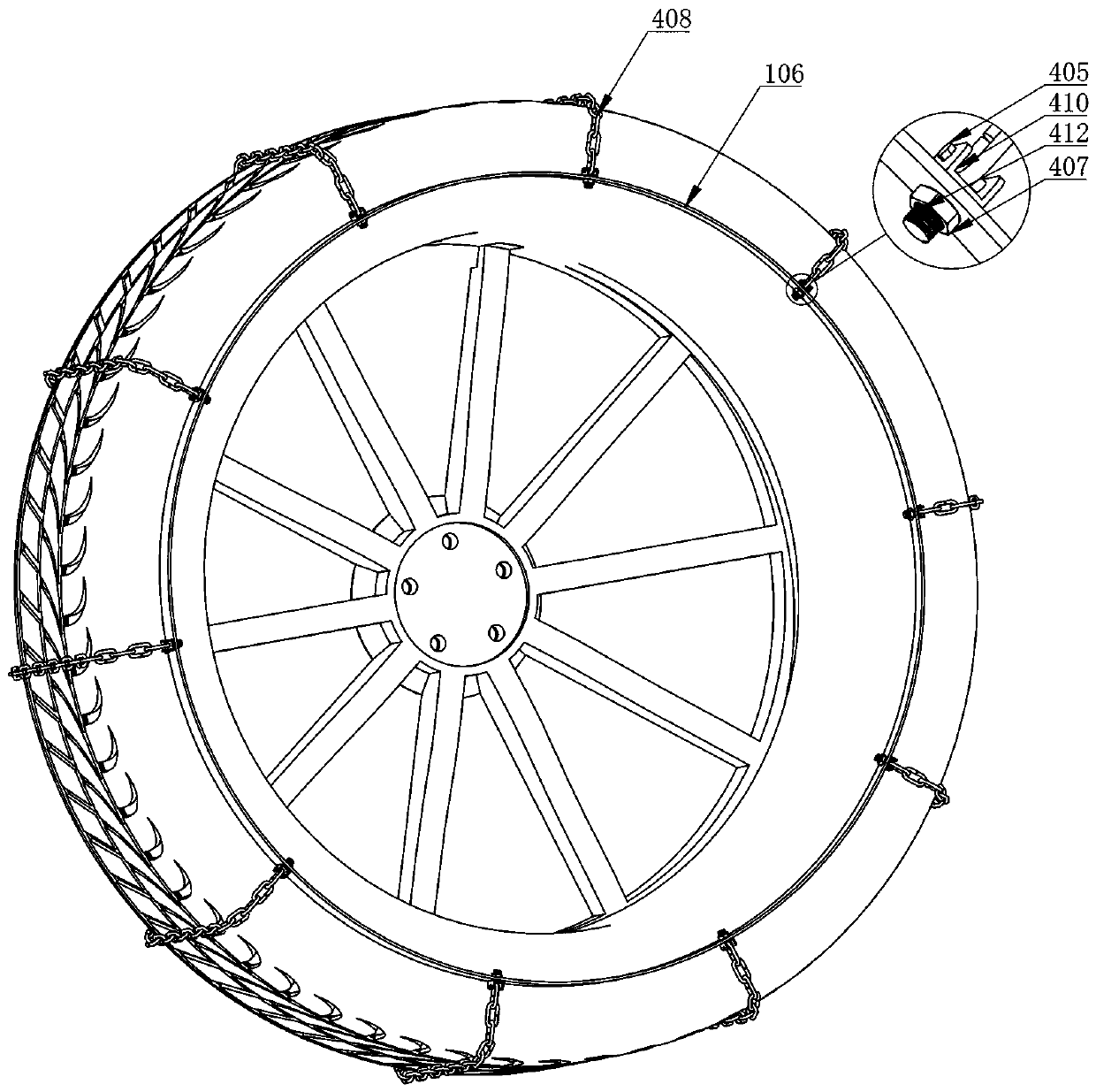

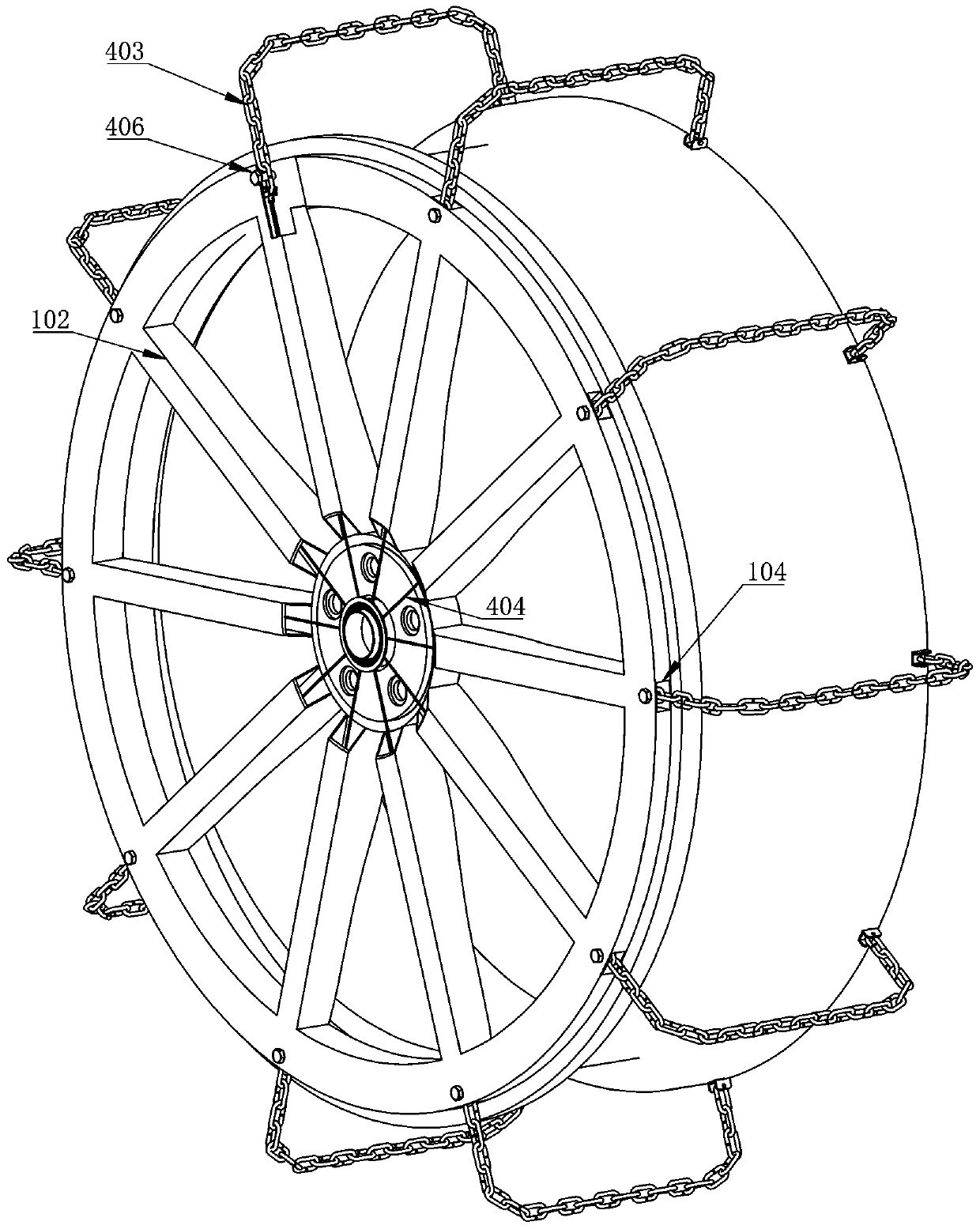

[0021] Embodiment 1: Combining Figure 1-7 As shown, a pull-out tire anti-skid wheel hub is characterized by: comprising a wheel hub 1, an outer tire 2, a sealing cover 3 and a quick-loading and dismounting anti-skid device 4; a fixed disk 101 is arranged in the middle of the wheel hub 1; A plurality of supporting spokes 102 are evenly arranged; a groove 103 is arranged on the left side of the fixing plate 101; a plurality of fixing holes 108 are evenly arranged on the outer periphery of the middle of the groove 103; Installed on the left side of the groove 103; the outer tire 2 is installed outside the hub 1; the quick-loading and dismounting anti-skid device 4 is installed outside the outer tire 2; The bayonet 405, the fixing bolt 406 and the lock nut 407; the middle part of the support spoke 102 is provided with a chute 104 in the longitudinal direction; the chain links 403 are connected to each other to form an anti-skid chain 408; The middle part of the snow chain 408 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com