Silicone sealant and preparation method thereof

A silicone sealant, gas phase method, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of low elongation at break, poor lasting adhesion of concrete pavement, debonding between colloid and gap interface, etc. problems, to achieve the effect of maintaining road traffic safety, improving road quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

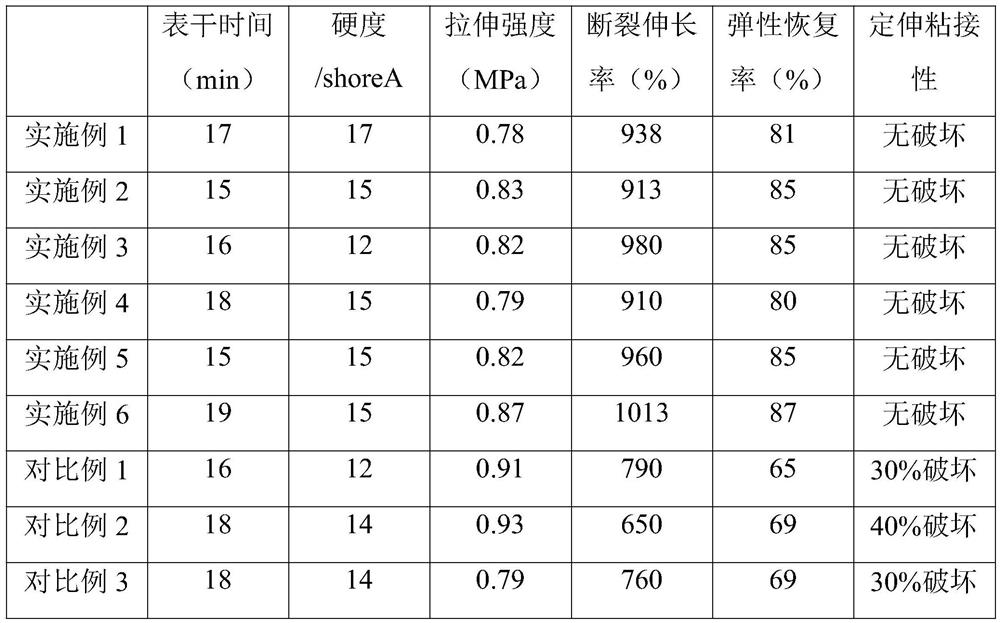

Examples

Embodiment 1

[0044] A concrete road seam is made of silicone sealant, made of a weight of the following weight:

[0045] α, ω-dihydroxy polymethylsiloxane: 100 parts

[0046] Heavy calcium carbonate: 130 copies

[0047] Gas phase method silica: 11 copies

[0048] Dimethylsilicone oil: 50 parts

[0049] Dimethyl dibutyl oxime silane: 2 parts

[0050] Methyl tributtyzine silane: 9 parts

[0051] Vinyl tributyltone silane: 3 parts

[0052] γ-aminopropyl triethoxysilane: 2 parts

[0053] Di-Jutikikikin 桂 酸: 0.1

[0054] The preparation method of silicone sealing gelatin with a concrete road seam is as follows:

[0055] A. A, ω-dihydroxy polyimethylsiloxane, heavy calcium carbonate, plasticizer, and gas phase method for 1.5 hours at room temperature to obtain a base;

[0056] B, a chain extender, a crosslinking agent, a coupling agent, and a catalyst were added to the base, and stirred at room temperature and a vacuum degree of 0.08 to 0.1 MPa, the silicone sealant was obtained.

Embodiment 2

[0058] A concrete road seam is made of silicone sealant, made of a weight of the following weight:

[0059] α, ω-dihydroxy polymethylsiloxane: 100 parts

[0060] Heavy calcium carbonate: 130 copies

[0061] Gas phase method silica: 11 copies

[0062] Dimethylsilicone oil: 50 parts

[0063] Dimethyl dibutyl oxime silane: 4 parts

[0064] Methyl tributtyzine silane: 9 parts

[0065] Phenyl tributyltone silane: 3 parts

[0066] γ-aminopropyl triethoxysilane: 2 parts

[0067] Di-Jutikikikin 桂 酸: 0.1

[0068] The preparation method of silicone sealing gelatin with a concrete road seam is as follows:

[0069] A. A, ω-dihydroxy polyimethylsiloxane, heavy calcium carbonate, plasticizer, and gas phase method for 1.5 hours at room temperature to obtain a base;

[0070] B, a chain extender, a crosslinking agent, a coupling agent, and a catalyst were added to the base, and stirred at room temperature and a vacuum degree of 0.08 to 0.1 MPa, the silicone sealant was obtained.

Embodiment 3

[0072] A concrete road seam is made of silicone sealant, made of a weight of the following weight:

[0073] α, ω-dihydroxy polymethylsiloxane: 100 parts

[0074] Heavy calcium carbonate: 130 copies

[0075] Gas phase method silica: 11 copies

[0076] Dimethylsilicone oil: 50 parts

[0077] Dimethyl dibutyl oxime silane: 6 parts

[0078] Vinyl tributyltone silane: 9 parts

[0079] Phenyl tributyltone silane: 3 parts

[0080] γ-shrinkion glycerol ether oxyl triethoxysilane: 2 parts

[0081] Di-Jutikikikin 桂 酸: 0.1

[0082] The preparation method of silicone sealing gelatin with a concrete road seam is as follows:

[0083] A. A, ω-dihydroxy polyimethylsiloxane, heavy calcium carbonate, plasticizer, and gas phase method for 1.5 hours at room temperature to obtain a base;

[0084] B, a chain extender, a crosslinking agent, a coupling agent, and a catalyst were added to the base, and stirred at room temperature and a vacuum degree of 0.08 to 0.1 MPa, the silicone sealant was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com