A kind of elastic alloy with high mechanical quality factor and its manufacturing method

A technology of mechanical quality factor and elastic alloy, which is applied in the field of elastic alloy, can solve the problems of poor uniformity and temperature stability, elastic alloy can not have both high mechanical quality factor and low frequency temperature coefficient, and achieve low frequency temperature coefficient , high mechanical quality factor, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

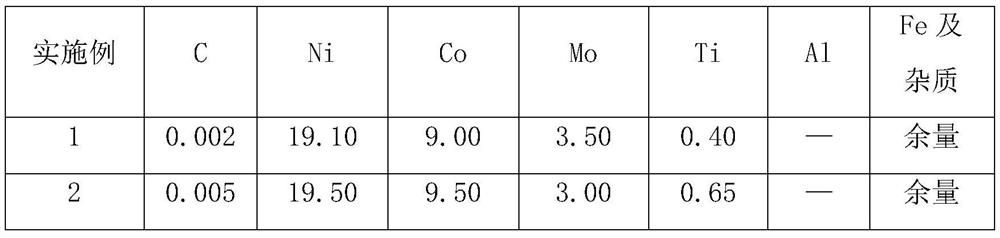

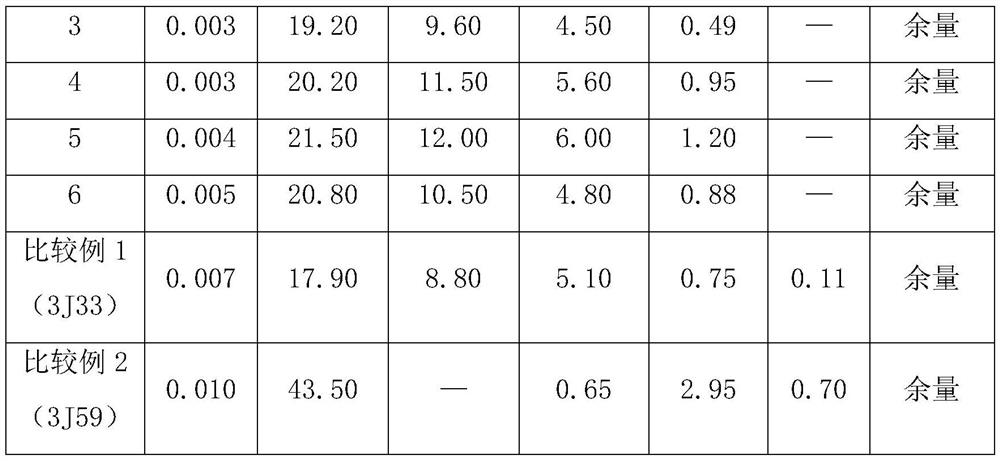

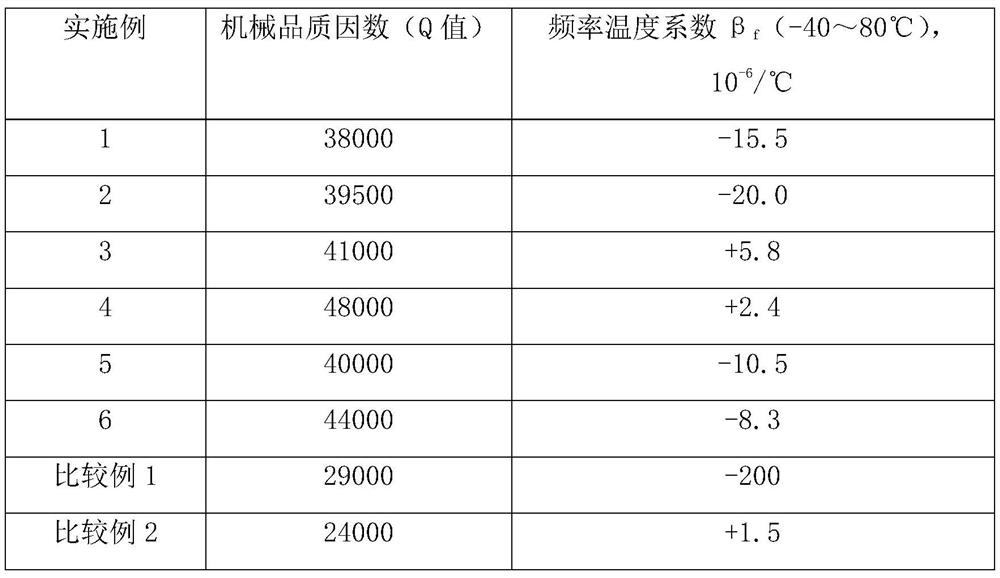

Examples

Embodiment 1

[0026] After the alloy ingot is homogenized and annealed at 1150°C for 15 hours, it is forged at 1200°C into a 60mm×60mm billet, and then hot-rolled at 1150°C into a Φ25mm bar. Finished bar heat treatment process: heating at 1050°C for 1 hour, water quenching to room temperature; heating at 820°C for 1.2 hours, air cooling to room temperature; finally aging treatment at 480°C for 8 hours, air cooling to room temperature.

Embodiment 2

[0028] After the alloy ingot is homogenized and annealed at 1180°C for 12 hours, it is forged at 1160°C into a 70mm×70mm billet, and then hot-rolled at 1180°C into a Φ30mm bar. Finished bar heat treatment process: heating at 1100°C for 0.5h, water quenching to room temperature; heating at 810°C for 1.5h, air cooling to room temperature; finally aging treatment at 520°C for 6h, air cooling to room temperature.

Embodiment 3

[0030] After the alloy ingot is homogenized and annealed at 1200°C for 10h, it is forged at 1150°C into a 90mm×90mm billet, and then hot rolled at 1120°C into a Φ40mm bar. Finished bar heat treatment process: heating at 1150°C for 0.5h, water quenching to room temperature; heating at 860°C for 1h, air cooling to room temperature; finally aging treatment at 550°C for 5h, air cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com