A steel structure spherical hinge bearing

A ball hinge bearing and steel structure technology, which is applied to building components, building structures, building types, etc., can solve problems such as the inability to build the building skeleton, the small stress area of the steel ball, and the inability to apply the building process to the spherical hinge bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

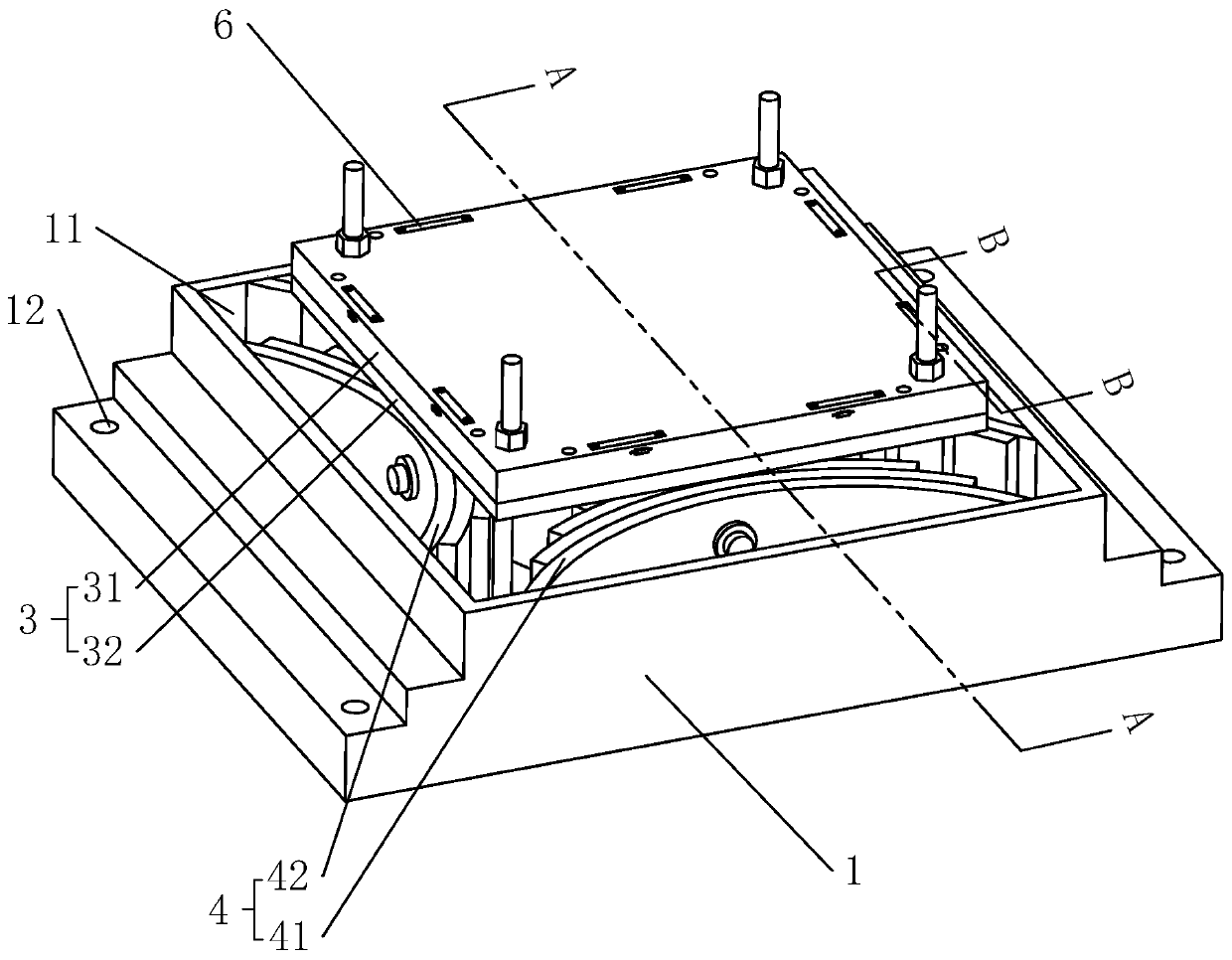

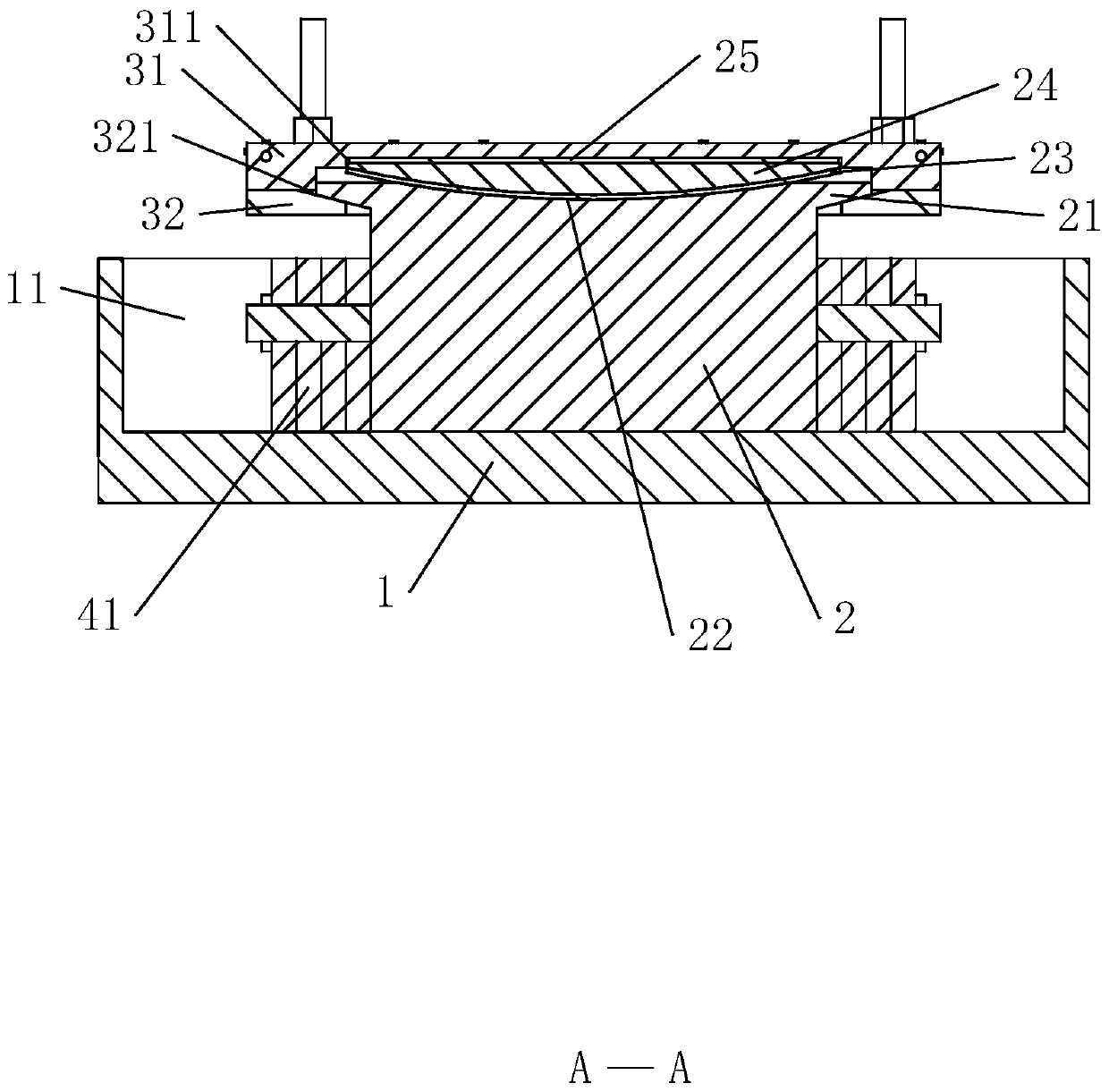

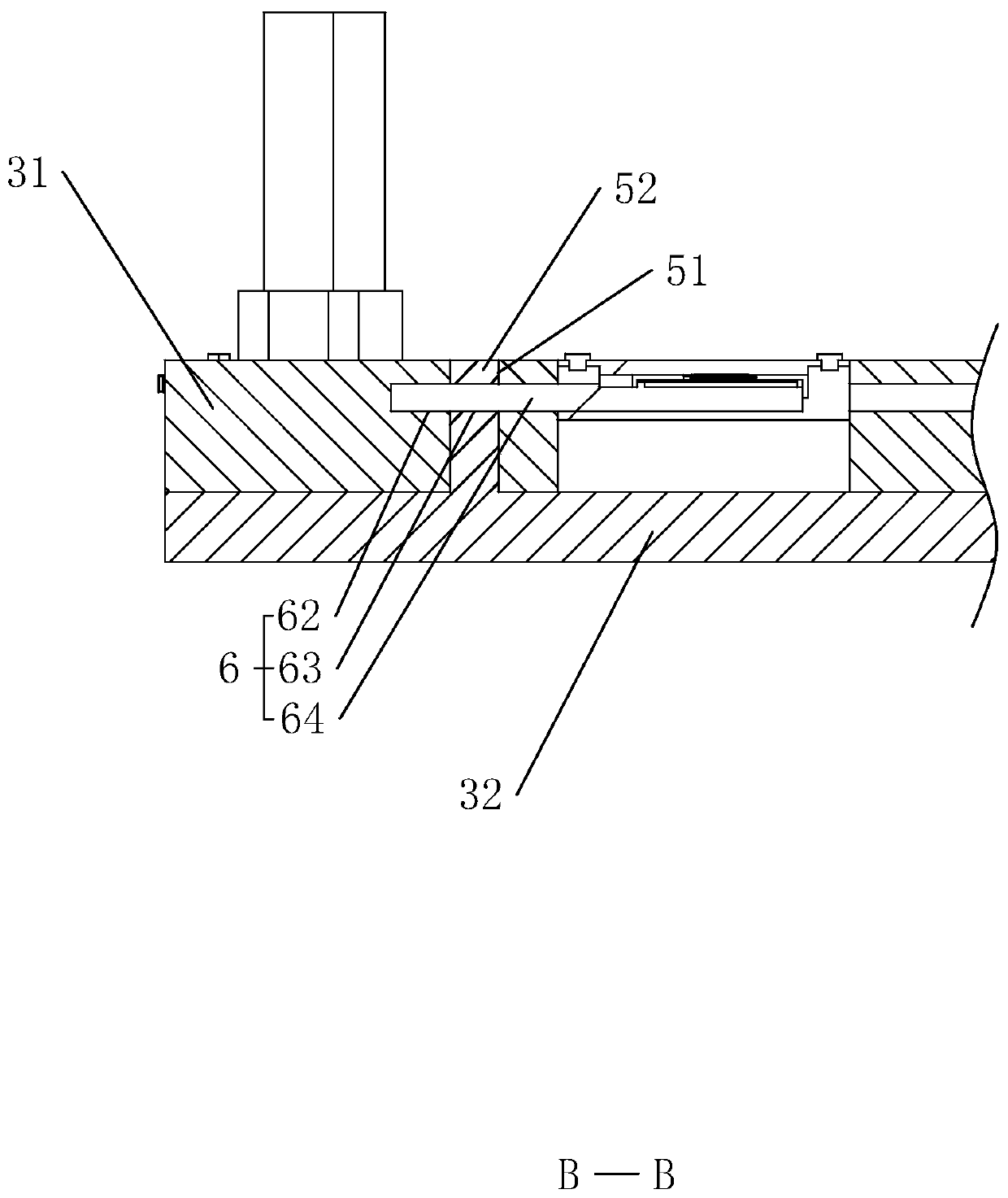

[0037] like figure 1 As shown, a steel structure spherical hinge support includes a lower support 1, a support block 2, and an upper support 3. The lower support 1 is quadrilateral, and a hole for the support block 2 to be loaded is formed at the center of the lower support 1. The bearing cavity 11 and the lower support 1 are provided with a plurality of connecting holes 12 distributed around the bearing cavity 11 and used for connecting with concrete piers on the construction site.

[0038] like figure 2 As shown, the support block 2 is cylindrical and placed in the bearing cavity 11. A wedge-shaped part 21 is integrally provided on the side wall of the support block 2 away from the lower support 1, and is arranged between the support block 2 and the lower support 1. There is shock absorbing assembly 4.

[0039] The damping assembly 4 includes more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com