Construction method based on building post-cast belt

A construction method and technology of post-pouring tape, which is applied in construction, on-site preparation of building components, and building construction, and can solve problems such as labor-intensive, delay in construction period, and quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention is based on the construction method of building post-pouring belt, comprises the following steps:

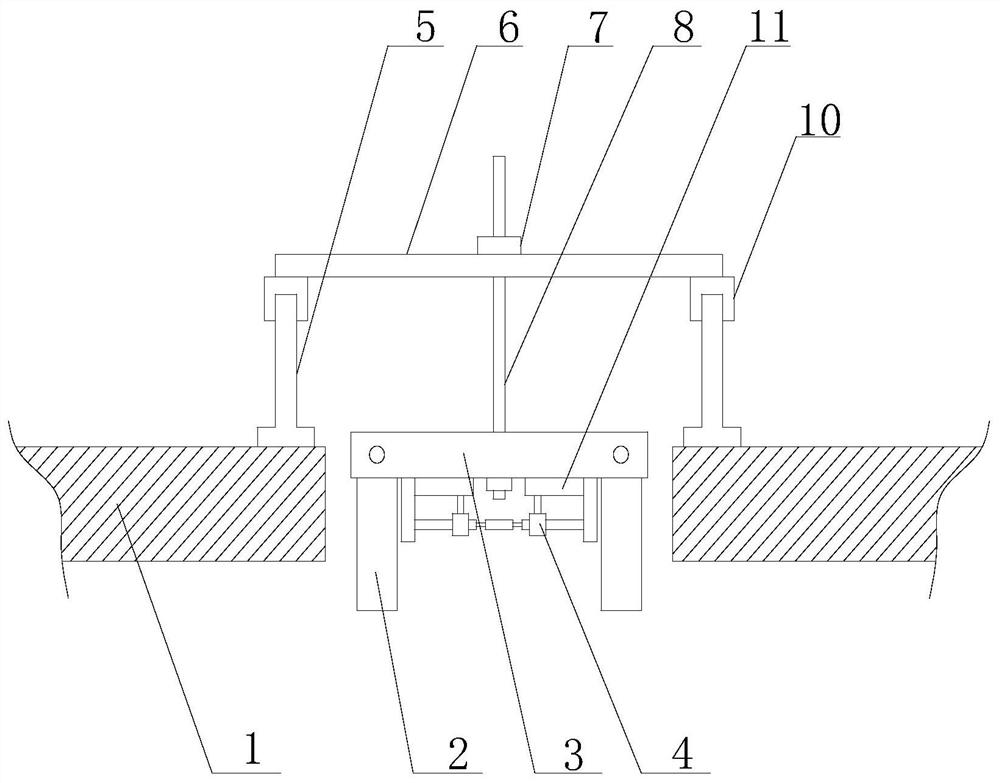

[0043] 1) Install the support frame 5 on the concrete 1 on both sides of the pouring belt 9 to be poured;

[0044] 2) Connect the moving block 10 to the support frame 5, so that the horizontal plate 6 is installed above the pouring belt 9 after pouring;

[0045] 3) Connect the threaded rod 8 connected to the template 3 with the horizontal plate 6 through the nut 7;

[0046] 4) Rotate the nut 7, and the threaded rod 8 drives the formwork 3 to move downward in the vertical direction, so that the formwork 3 passes through the pouring belt 9 to reach the bottom of the pouring belt 9;

[0047] 5) Build a ladder on the lower floor of the concrete 1, the construction workers climb up the ladder, unfold the two folded movable support plates 2, and ensure that the formwork 3 is flush with the movable support plates 2;

[0048] 6) Use the movable block 4 to ...

Embodiment 2

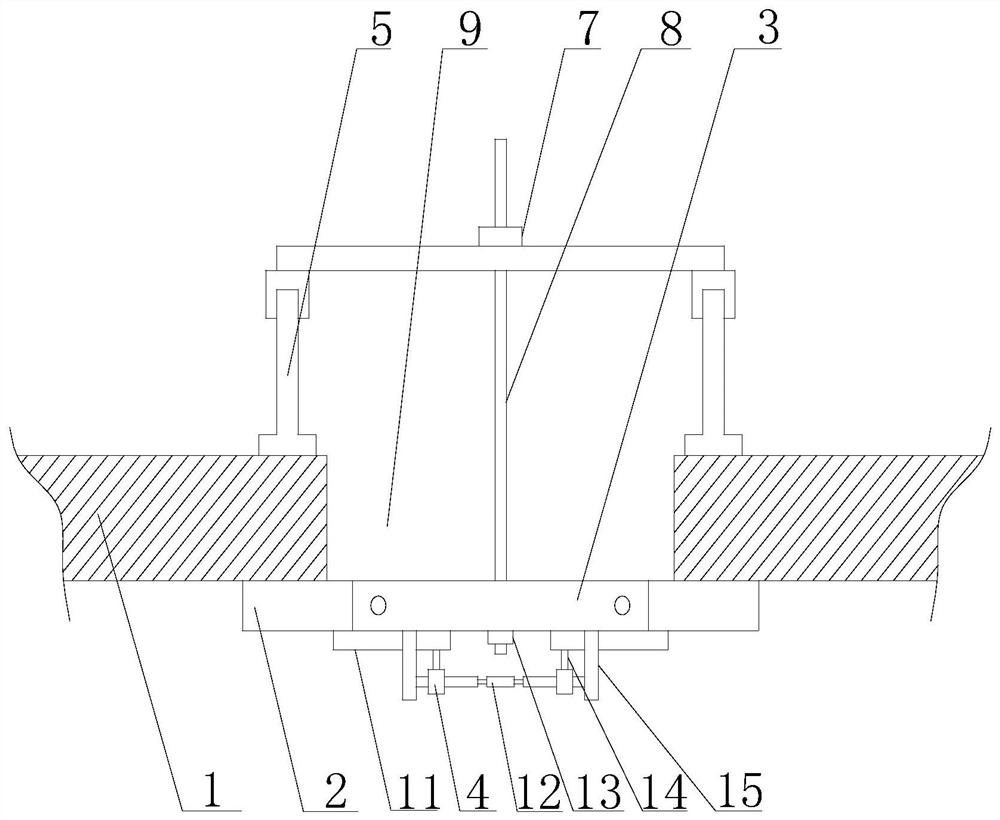

[0056] On the basis of Embodiment 1, the fixed assembly includes a rotating rod 12, two first connecting blocks 15, and two moving plates 11. The first connecting blocks 15 are respectively located on both sides of the axis of the template 3, and the rotating rod 12 The two ends of the two first connecting blocks 15 are respectively connected, and the rotating rod 12 can rotate in the first connecting block 15, the moving plate 11 is located at the bottom of the template 3, and the moving plate 11 runs through the first connecting block horizontally 15, the rotating rod 12 is rotated, and the moving plate 11 can move horizontally in the connecting block. The two ends of described rotating bar 12 are all provided with movable block 4, and movable block 4 is connected with rotating bar 12 by screw thread, and described movable block 4 is all provided with connecting rod 14, and connecting rod 14 is connected with moving plate 11, movable When the block 4 moves on the rotating ro...

Embodiment 3

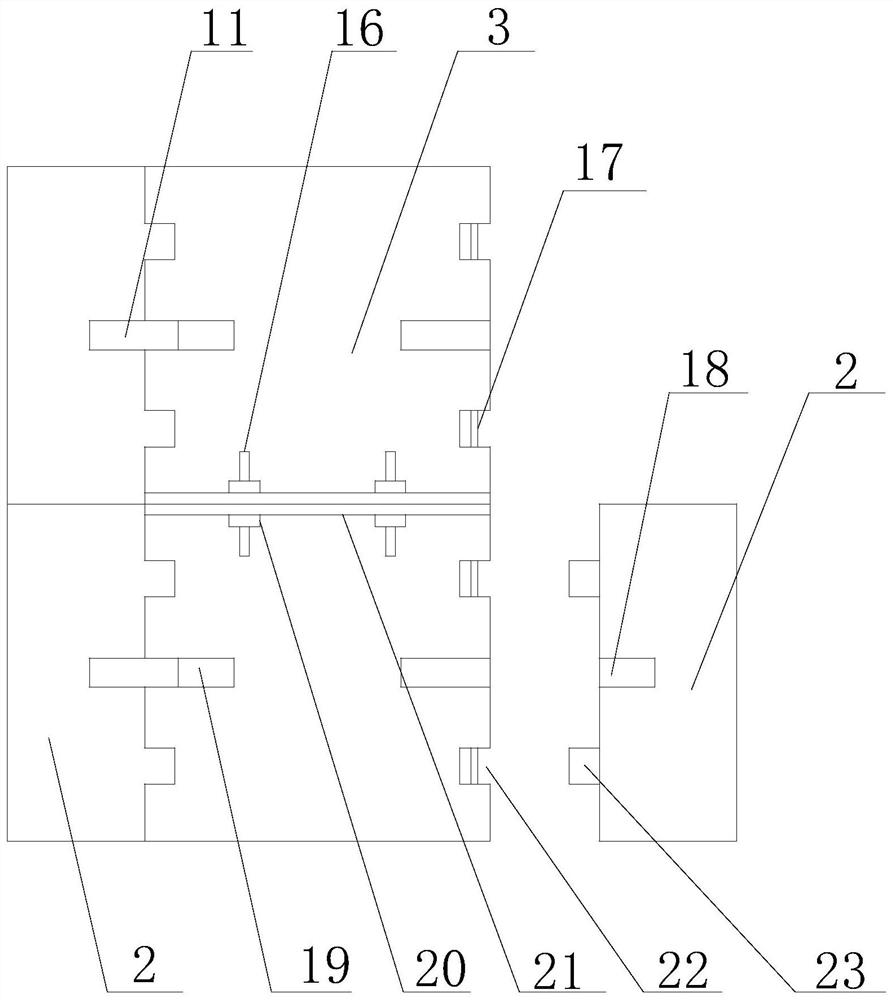

[0058] On the basis of Embodiment 2, two connecting grooves 22 are provided at both ends of the template 3, and two connecting grooves 22 matching the connecting grooves 22 are provided on the side wall of the movable support plate 2 facing the template 3. Two connecting blocks 23, the second connecting block 23 is located in the connecting groove 22, the movable shaft 17 is also provided in the connecting groove 22, and the movable shaft 17 is inserted in the second connecting block 23, the second connecting block 23 can move Rotate on axis 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com