Method for drainage and grouting of stratifugic water

A layer separation and dredging technology, applied in drainage, earthwork drilling, filling, etc., can solve the problems of long duration, roadway occupation, low drainage efficiency, etc., and achieve the effect of reducing surface movement and deformation, and preventing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the invention, but it should be understood that the protection scope of the invention is not limited by the specific embodiments.

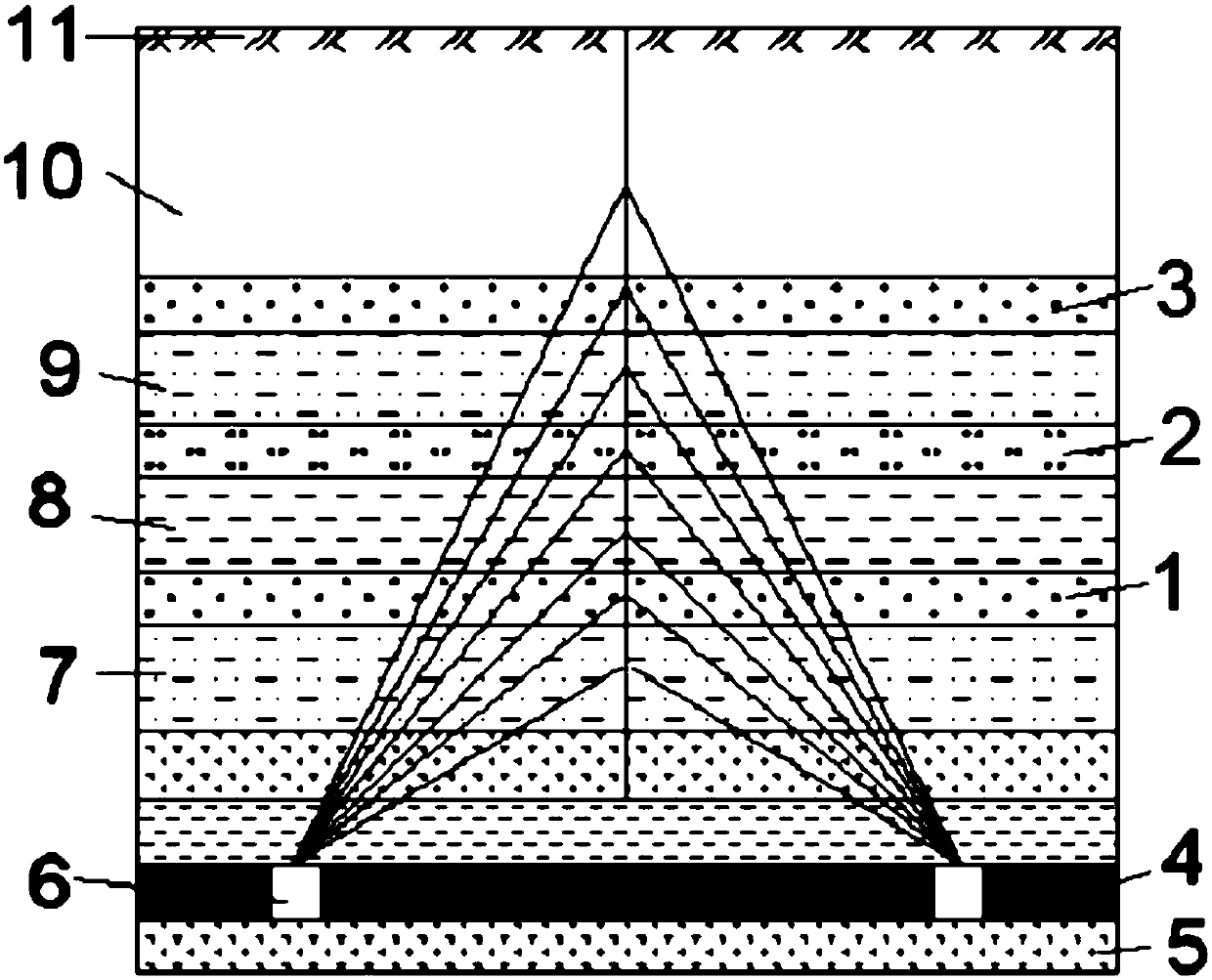

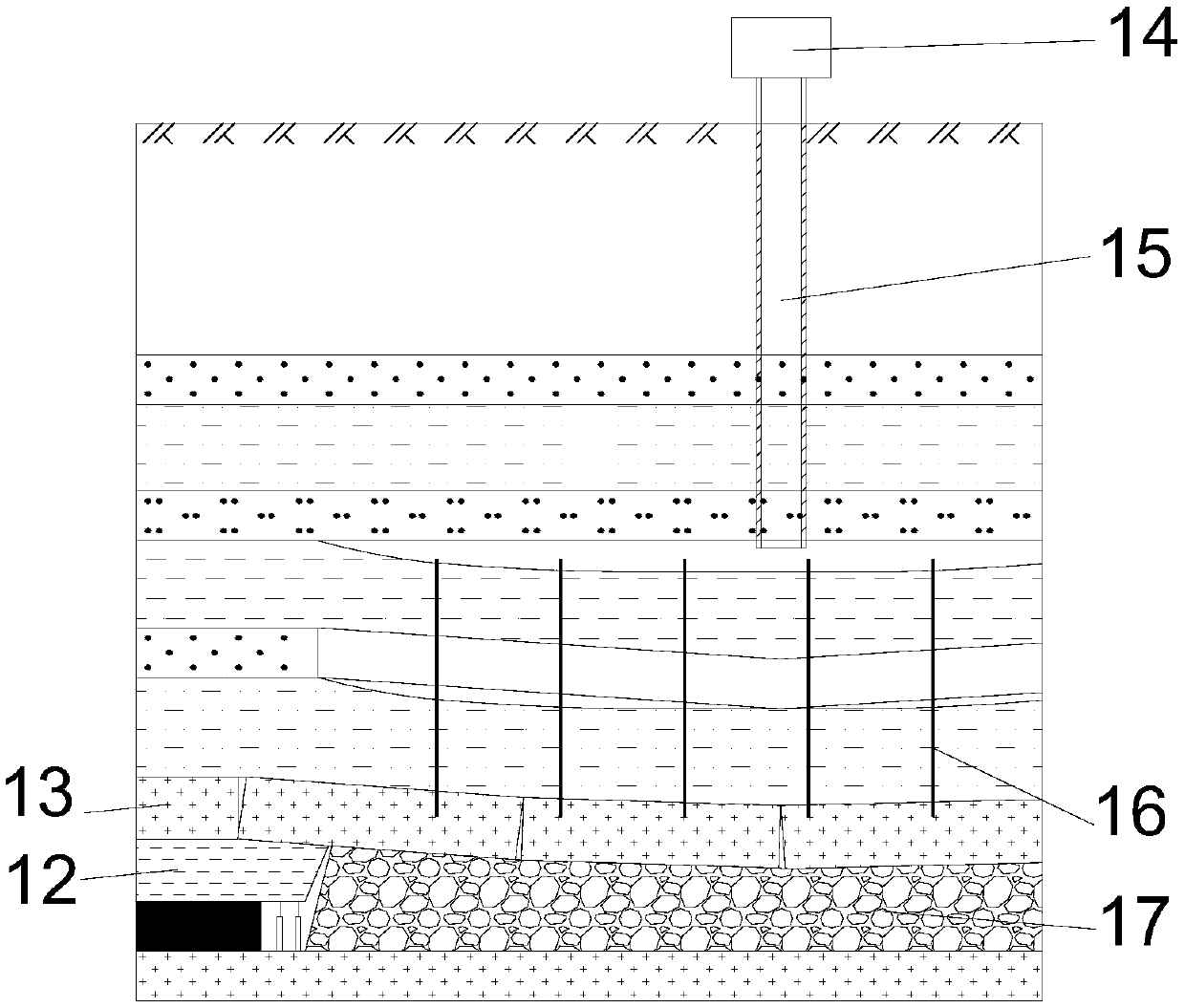

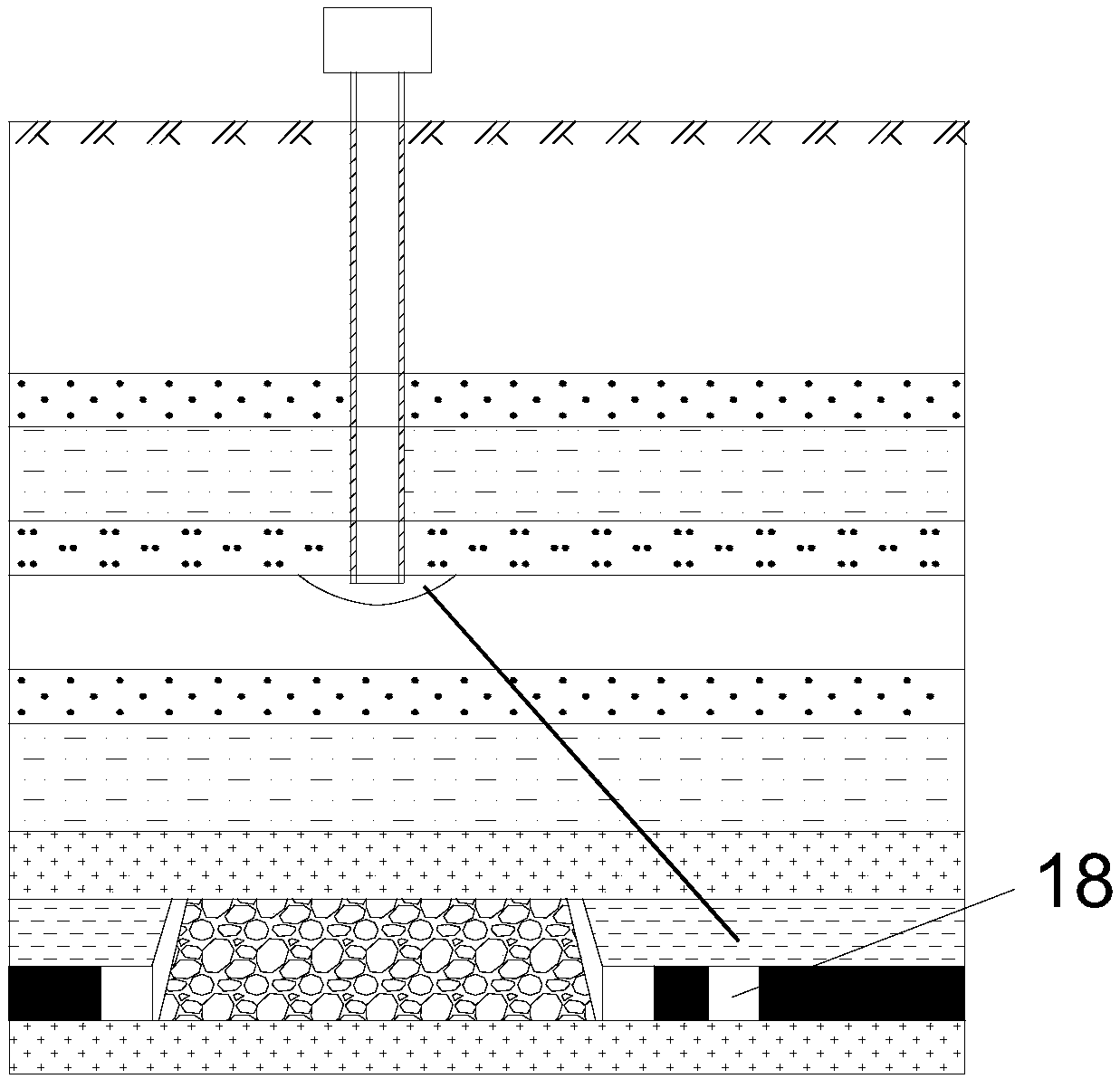

[0026] refer to Figure 1-4 , the invention provides a kind of delamination water drainage grouting method, comprises the following steps:

[0027] Step 1. First determine the location of the aquifer in the overlying strata of the mining area and the location of the water inrush source, and then use the aquifer discrimination method to determine the location of the aquifer; that is, first determine the positions of the bottom coal seam 4 and the floor rock layer 5 .

[0028] The geophysical prospecting method was selected to detect the overlying strata in the mining area, and the location of the water inrush source in the upper strata was determined; and then the aquifer discrimina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com