Engine valve mechanism and engine

A valve train, engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of power drop, low efficiency, difficult to start, etc., to reduce assembly tact, improve production efficiency, and reduce replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

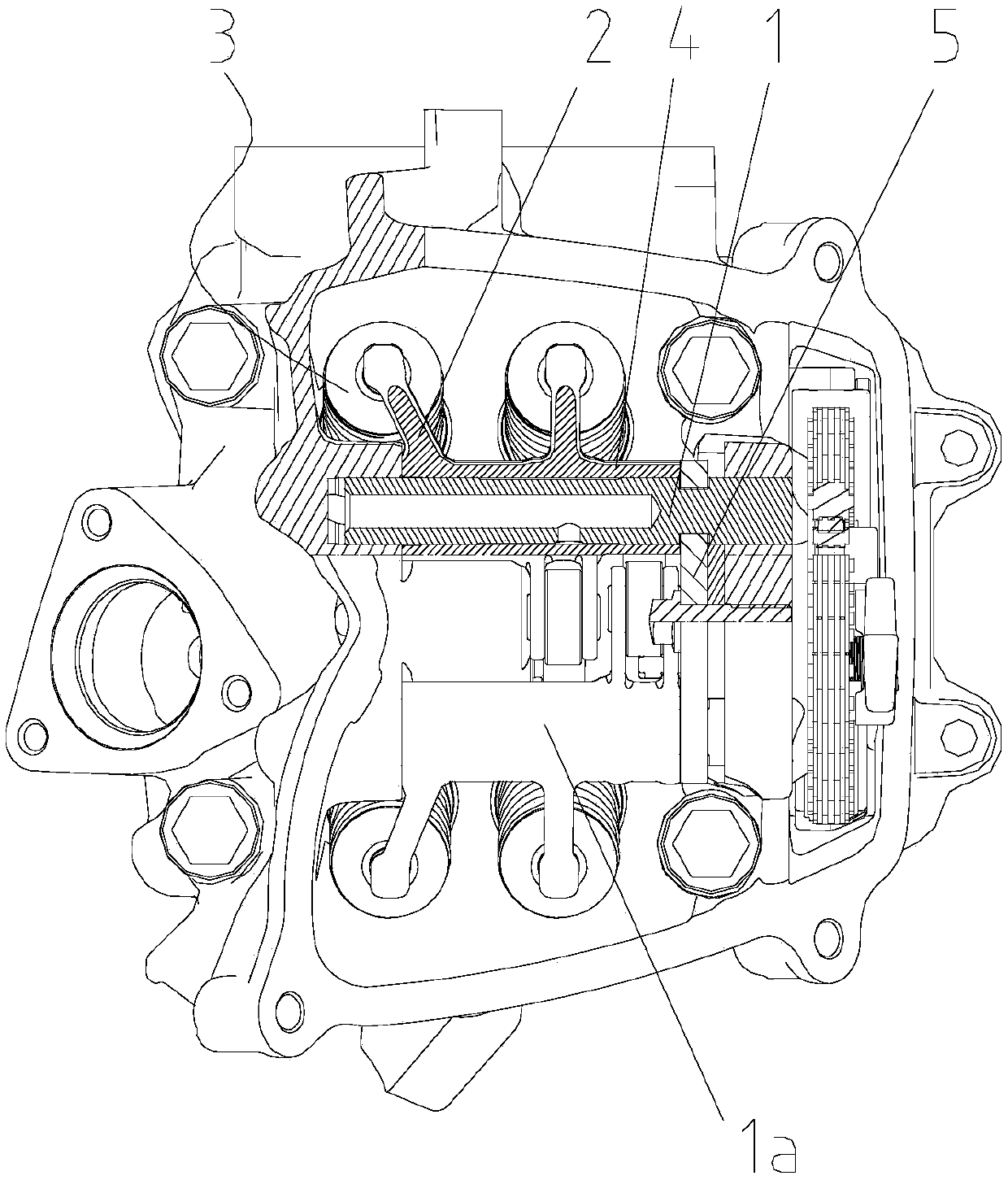

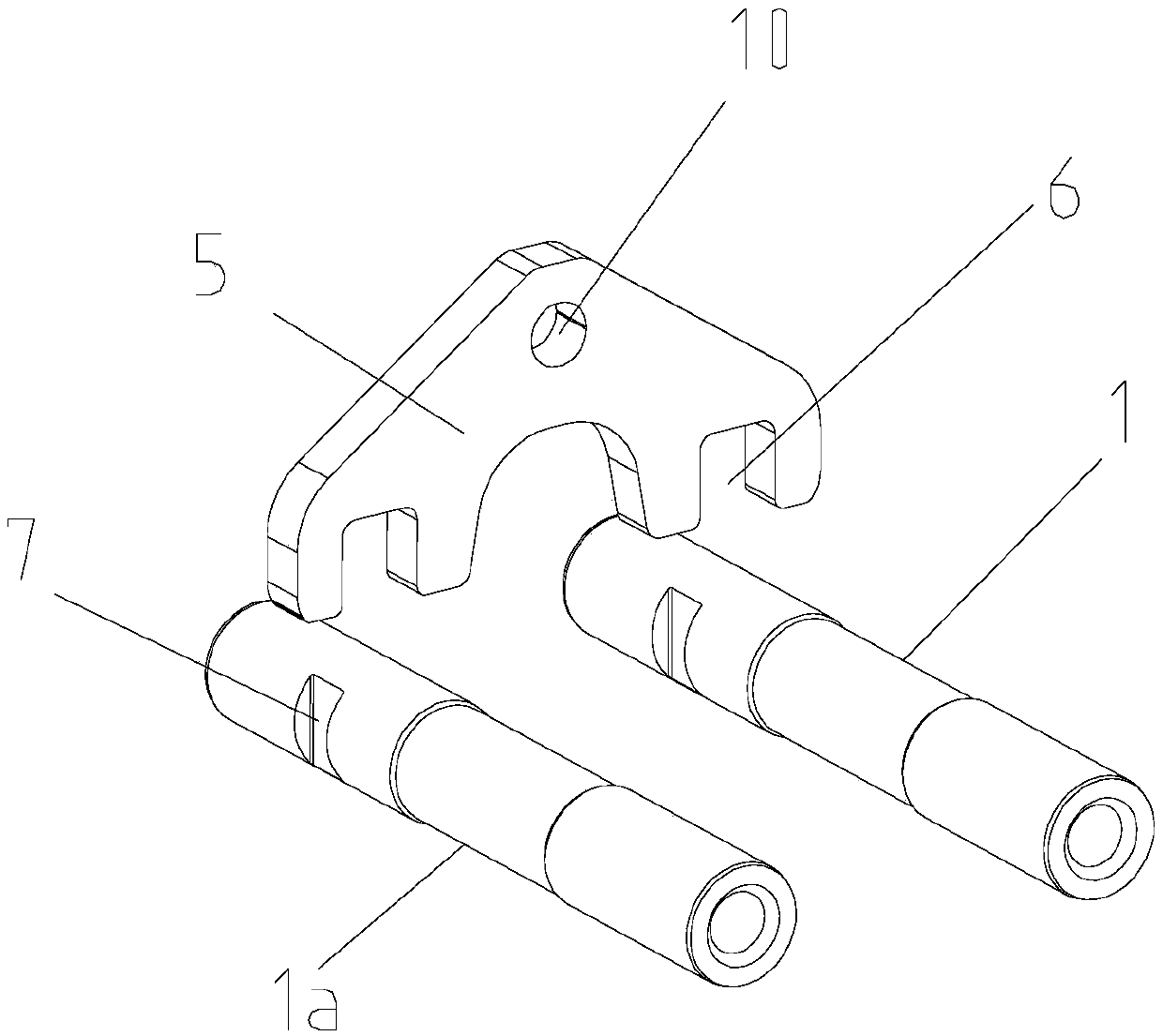

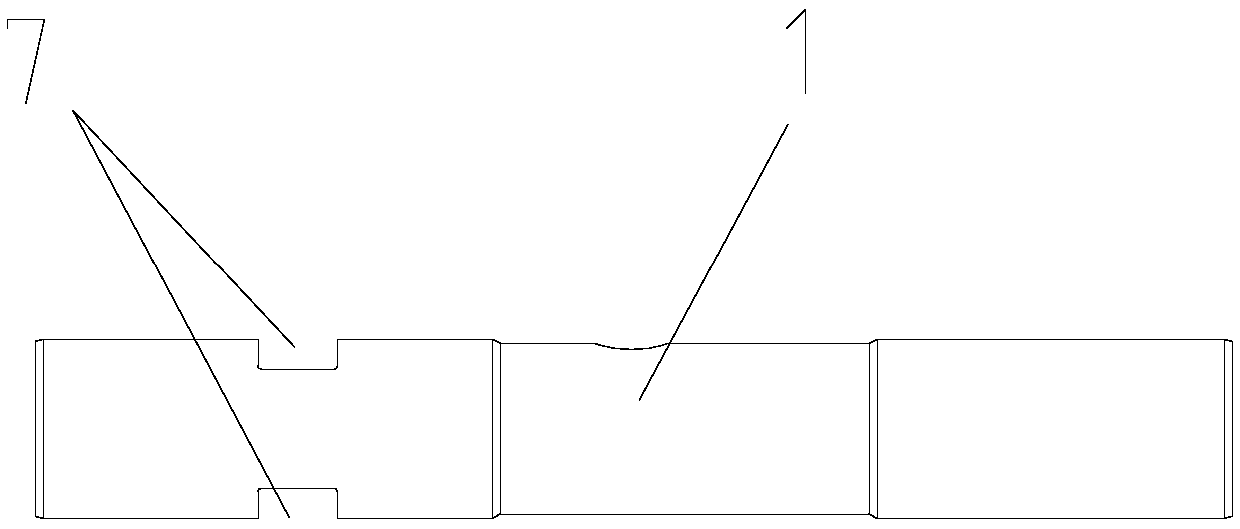

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the installation structure of the rocker shaft limit plate in the present invention, image 3 It is a structural schematic diagram of a rocker shaft or a camshaft in the present invention, Figure 4 It is a schematic diagram of the connection between the rocker arm limiting plate and the cam limiting plate in the present invention. As shown in the figure, the engine valve mechanism in this embodiment includes a valve assembly 3, a rocker assembly that is in transmission cooperation with the valve assembly 3, and is used for A drive assembly for driving the rocker arm assembly, the rocker arm assembly includes a rocker arm shaft 1 and a rocker arm 2 swingably mounted on the rocker arm shaft 1 along the circumferential direction, and the rocker arm 2 can be limited along the axial direction of the rocker arm shaft 1 Axial sliding arrangement in the way of posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com