Range hood and control method thereof

A control method and a technology for absorbing oil fume, which can be applied in the direction of removing oil fume, heating methods, household heating, etc., can solve the problem that the suction of the smoking port cannot be self-adapted, and achieve the effect of improving work flexibility and absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

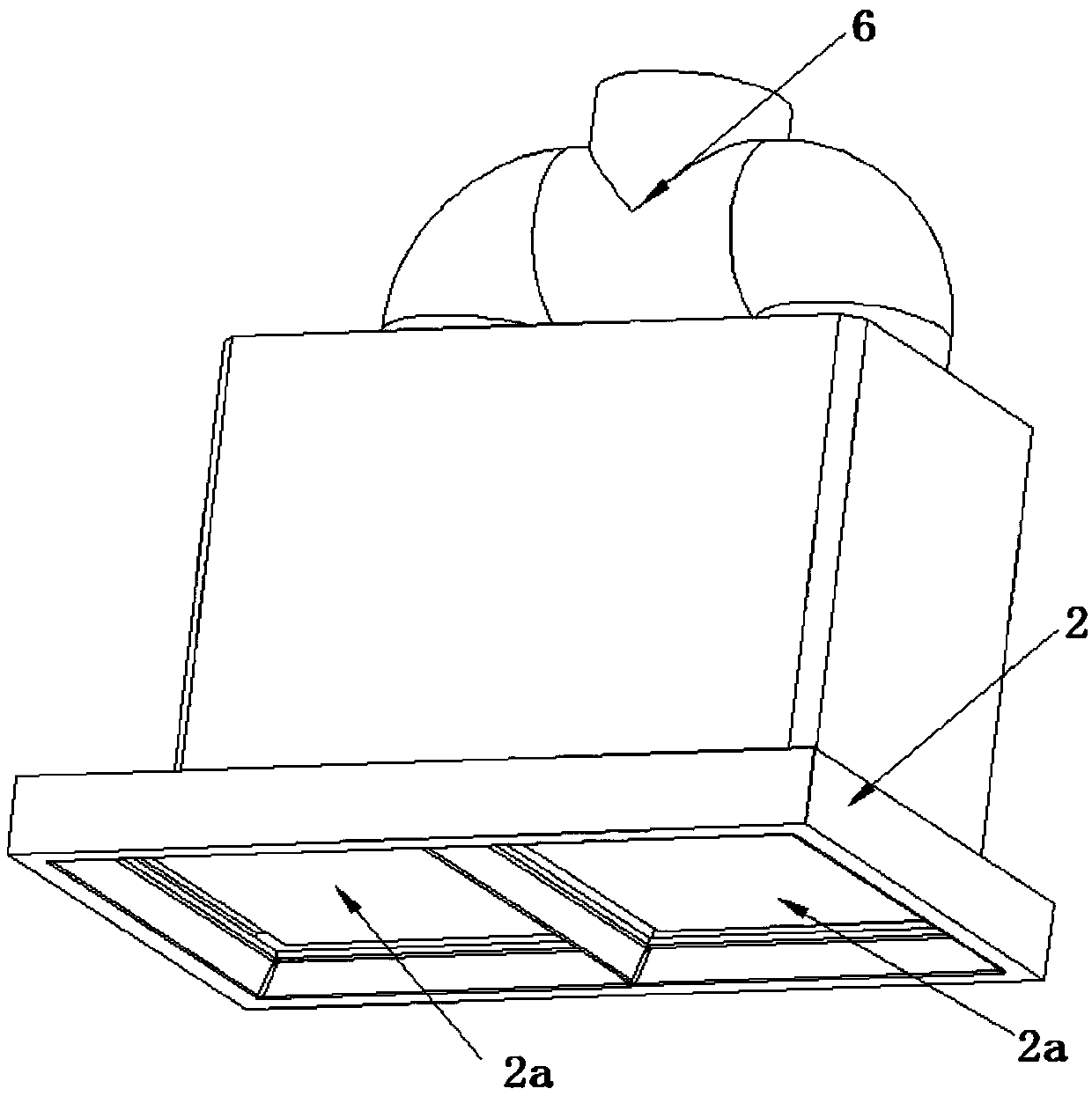

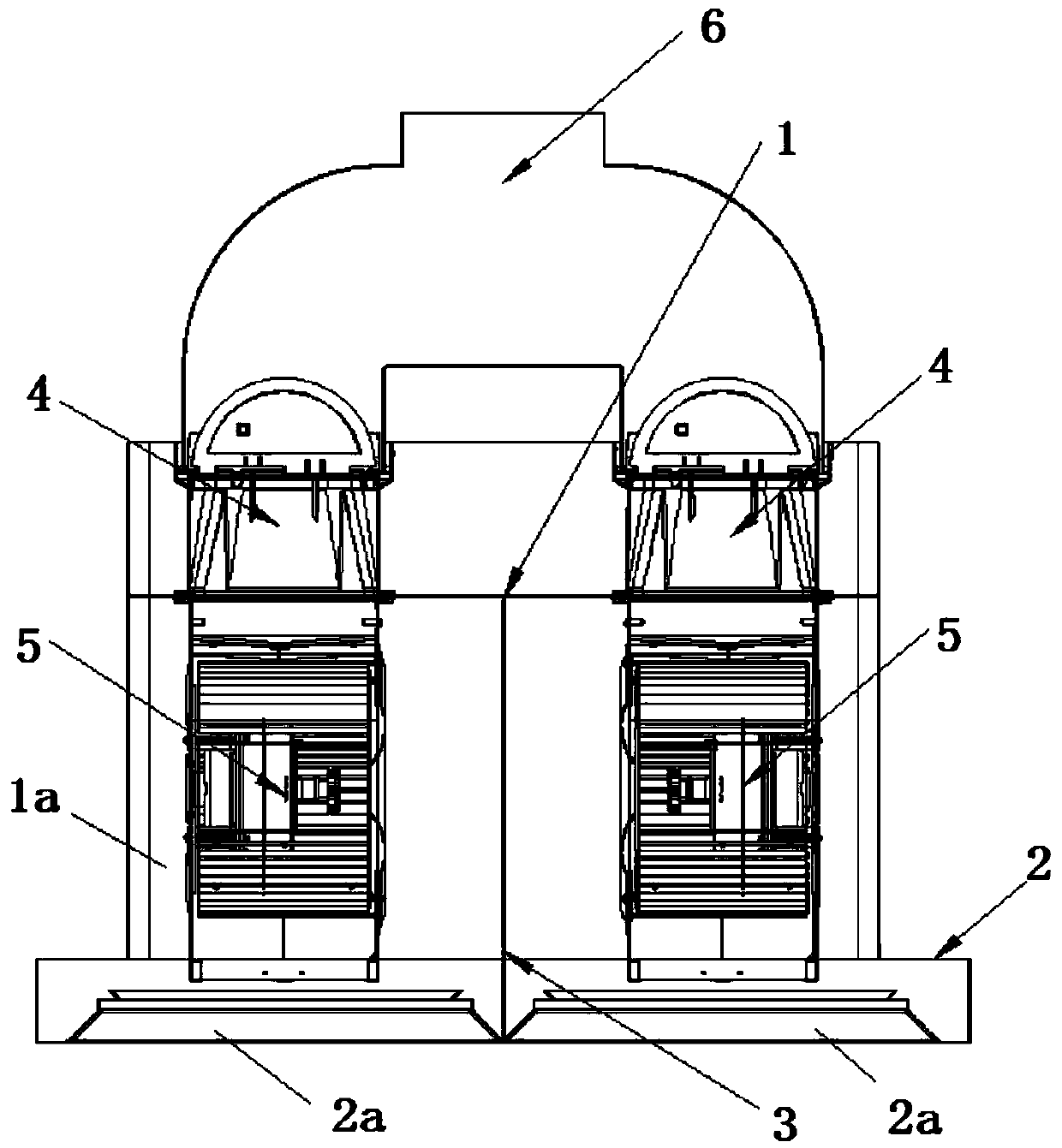

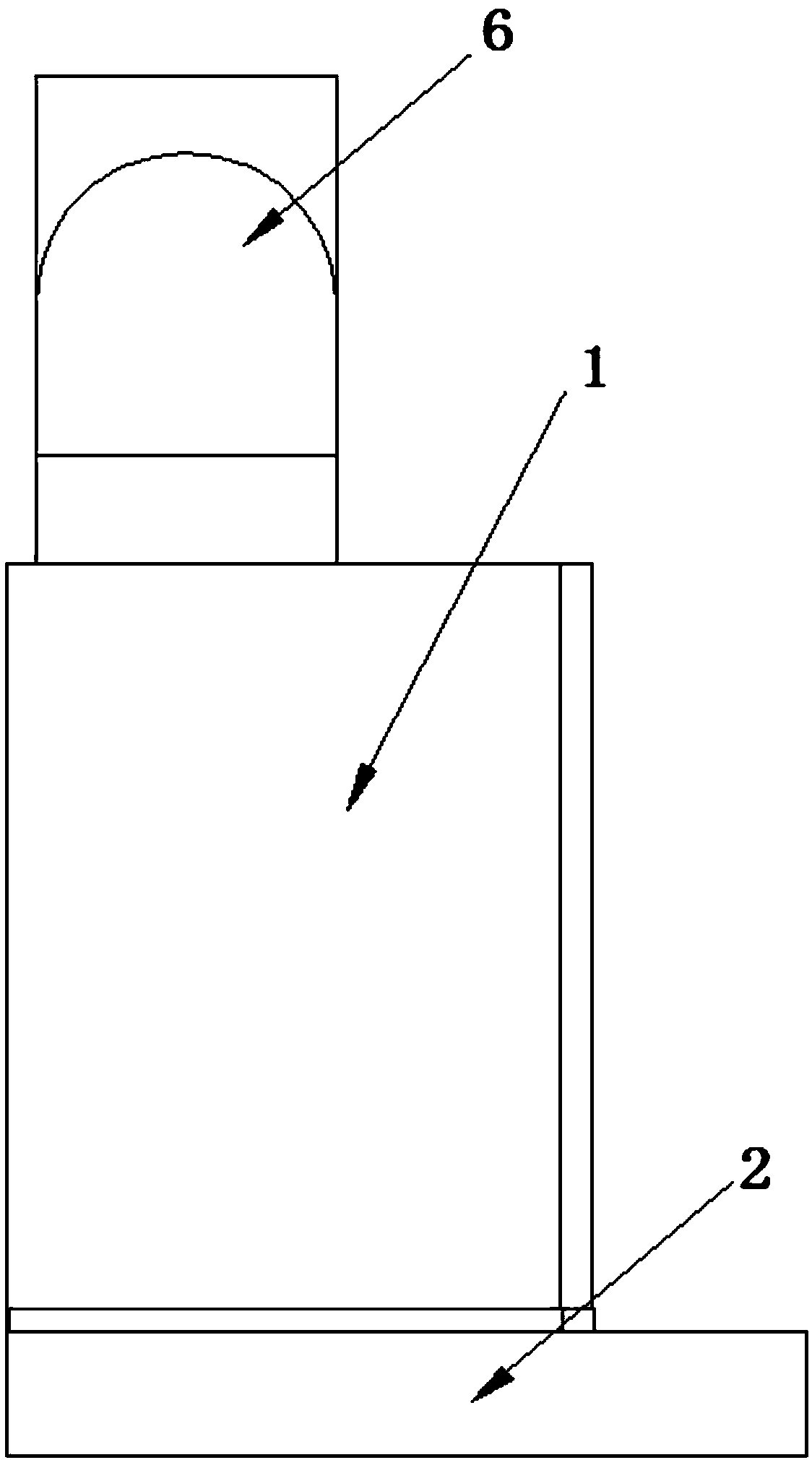

[0038] This embodiment provides this embodiment provides a range fume device, such as figure 1 , figure 2 with image 3 As shown, it includes: a cabinet 1, which is provided with a smoking chamber 1a; a smoke collecting hood 2, which is connected to the cabinet 1, and the smoke collecting hood 2 is provided with several smoking ports communicating with the smoking chamber 2a; several sets of fan systems 5 corresponding to the smoking openings 2a are arranged in the smoking cavity and respectively absorb the smoke entering each of the smoking openings 2a.

[0039] In this embodiment, there are multiple smoking chambers inside the cabinet 1, and a fan system 5 is separately arranged in each smoking chamber, and the speed of each fan system 5 can be controlled by the control system, thereby greatly improving the efficiency of the entire range fume device. Work flexibility. For example, when there is a situation where one smoking port 2a has a large smoke volume and the other ...

Embodiment 2

[0048] This embodiment provides a method for controlling the oil suction device provided in Embodiment 1, including the following steps: obtaining the first smoke volume of the first smoking port 2a; judging whether the first smoke volume is greater than or greater than a set threshold ; When the first flue gas volume is greater than the set threshold, start the first fan system corresponding to the first flue gas port.

[0049] The oil fume device includes at least one second smoking port 2a, obtains the second smoke volume of the second smoking port 2a; judges whether the second smoke volume is greater than or greater than the set threshold; when the second smoke volume is greater than the set threshold , start the second blower system 5 corresponding to the second flue gas port.

[0050] Through the above steps, it is possible to effectively control whether the fan system corresponding to the first flue gas port or the second flue gas port is activated. In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com