A method and equipment for improving the utilization rate of active material of the pole plate

A technology of active material and utilization rate, applied in the direction of lead-acid battery electrodes, etc., can solve the problems affecting the utilization rate of active material, low utilization rate of active material, and high utilization rate of active material, so as to improve the battery reserve capacity and improve the utilization of active material. rate, and the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and technical scheme, the present invention is described in further detail:

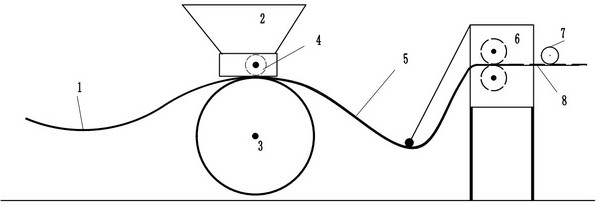

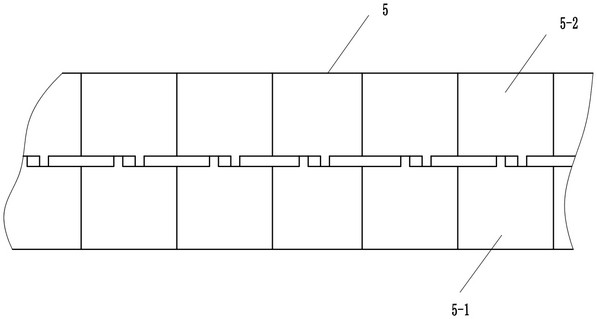

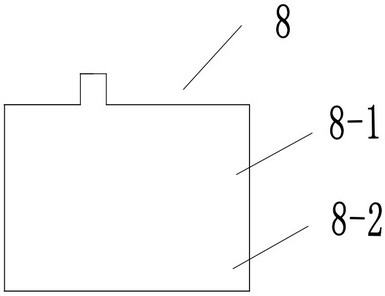

[0023] figure 1 Among them, it includes the frame of the coating and filling machine for producing wet plates, the coating and filling machine head 2 arranged above the frame and the wheel hub 3 below, the pressure roller 4 in the coating and filling machine head, and the slitting machine for cutting wet plates 6. A rubber pressure wheel 7 for reducing the deformation of the polar plate, and a cutting knife is arranged in the slitting machine 6 . The pressure roller 4 is located above the wheel hub 3, and the central axis of the pressure roller 4 is parallel to the central axis of the wheel hub 3; the roller surface of the pressure roller 4 includes a working section B and a non-working section A, and the non-working section A is located in the middle of the pressure roller 4 , the two ends of the non-working section A are symmetrically divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com