The process of secondary processing of seasoned prefabricated beef into stewed beef products

A technology for braised beef in sauce and secondary processing, applied in food science and other directions, can solve the problems of reduced water activity value of braised beef in sauce, inability of fresh beef to participate in international trade, and high semi-complete yield rate, which is beneficial to product storage. , The effect of high semi-complete yield and reduced water activity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the production method for secondary processing of prefabricated beef products into stewed beef products in sauce is as follows:

[0024] Operation process: precooked beef (control group: non-precooked) → frying → marinating → cooking → finished product;

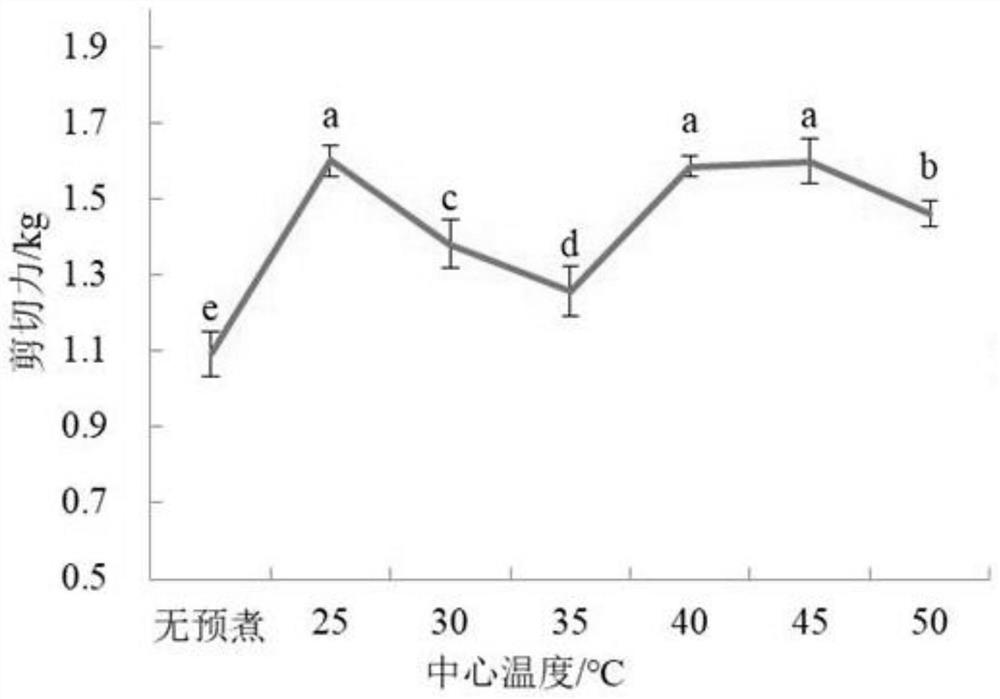

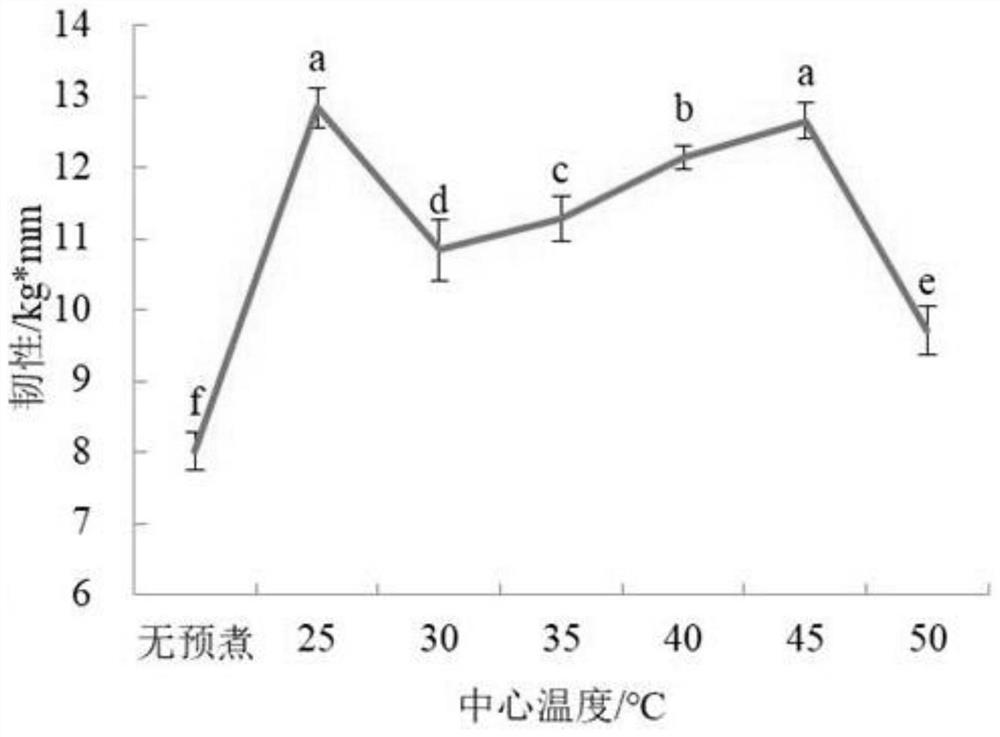

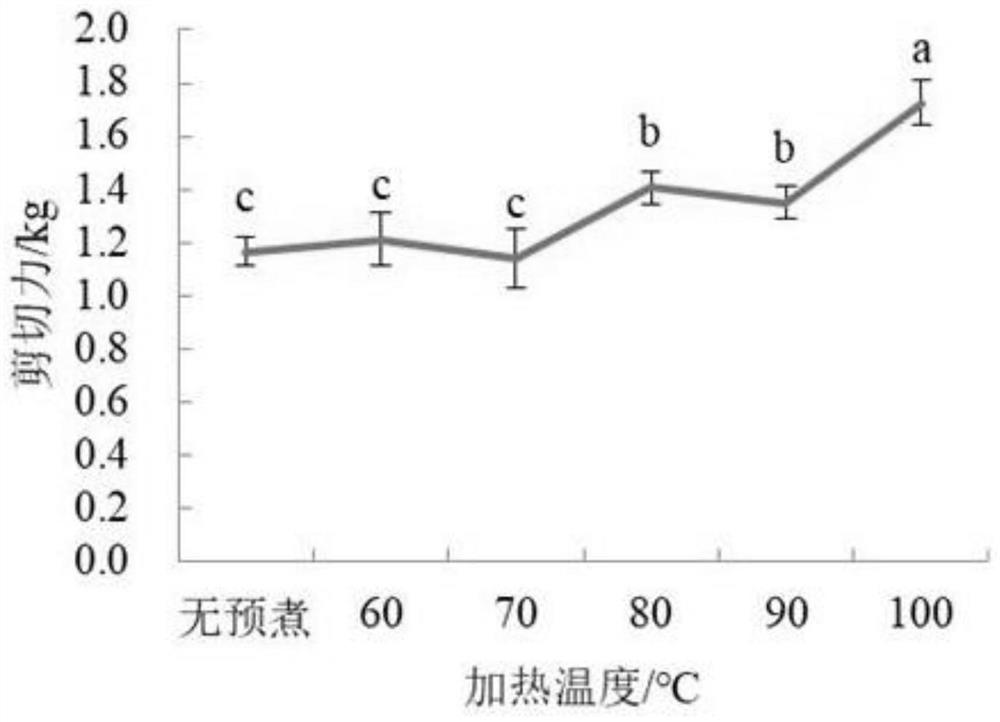

[0025] (1) Pre-cooked beef: Divide fresh beef into meat pieces of about 6cm×6cm×6cm; water bath at 4-25°C until the center temperature is 10°C, then add water at 60, 70, 80, 90, 100°C for high and low temperature cooking , Strictly control the cooking temperature, when the center temperature reaches 25°C, 30°C, 35°C, 40°C, 45°C, 50°C, take it out, put it in a vacuum packaging bag, and cool it in ice water;

[0026] (2) Stir-fry: Stir-fry shallots (1.1%, percentage of meat weight), ginger (1.1%), cinnamon (0.32%), star anise (0.4%), and Chinese prickly ash (0.26%) with hot oil to get the flavor out, then put Add the pre-cooked beef and stir-fry quickly, so that the surface of the beef is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com