A process for secondary processing of pre-conditioned beef into beef jerky products

A secondary processing and beef jerky technology, applied in food drying, dry preservation of meat/fish, food science, etc., can solve the problems of missing consumption objects, difficult chewing, easy damage to teeth, etc., achieve soft and hard taste, and extend shelf life period, the effect of increasing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

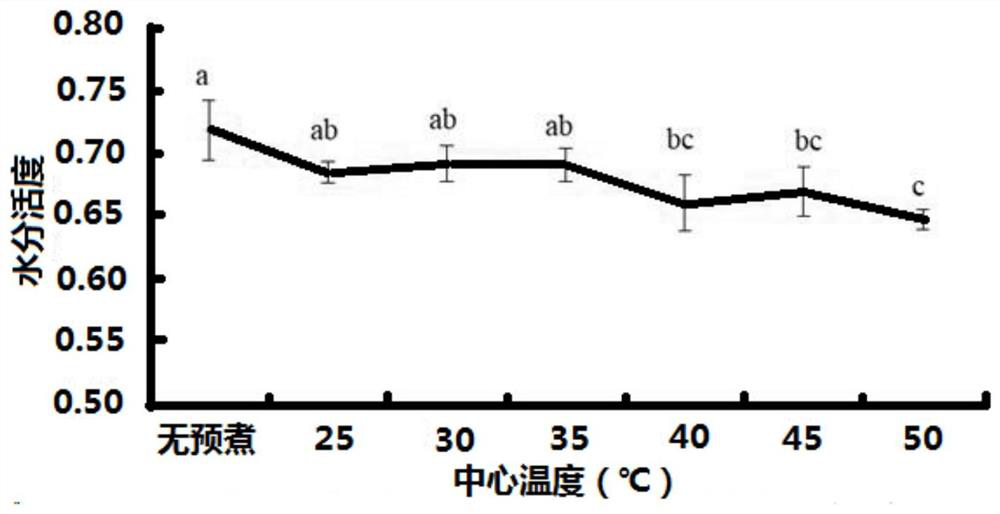

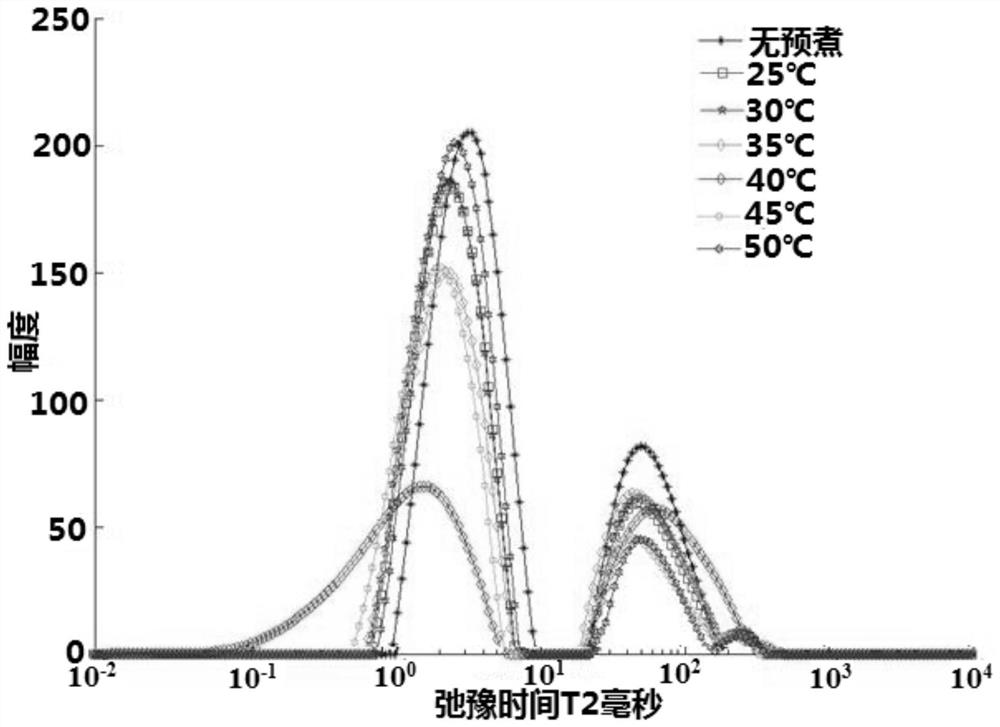

[0023] The present embodiment adjusts the production method of prefabricated beef products for secondary processing into beef jerky products, and the steps are as follows:

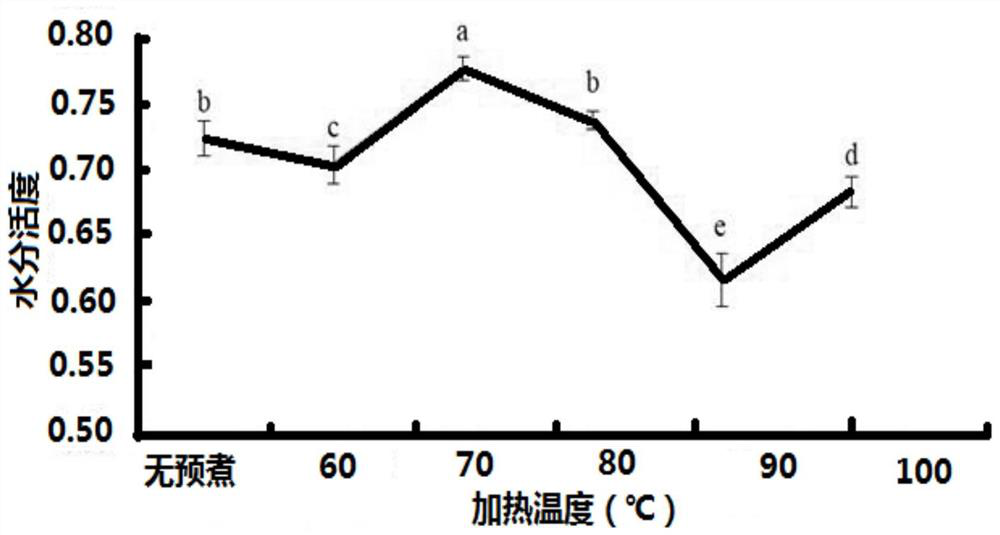

[0024] (1) Pre-cooked beef: Cut the fresh beef into 6cm×6cm×6cm pieces; take it out from a 4℃ water bath until the center temperature reaches 10℃, absorb the surface moisture with absorbent paper, and then put it in 90℃ water for high and low temperature Cooking, strictly control the cooking temperature, take it out when the central temperature reaches 40°C, put it into a vacuum packaging bag, and finally cool it quickly in ice water to get pre-cooked beef;

[0025] (2) Secondary precooking (setting): add the precooked beef into boiling water and cook for 20 minutes, add fresh ginger with 1% of the weight of the precooked beef to remove the peculiar smell; take it out and cool it naturally, and filter the soup for later use;

[0026] (3) Slicing: Cut the second precooked beef into 0.5cm thin slices, requir...

Embodiment 2

[0031] The present embodiment adjusts the production method of prefabricated beef products for secondary processing into beef jerky products, and the steps are as follows:

[0032] (1) Pre-cooked beef: Cut the fresh beef into 6cm×6cm×6cm pieces; take it out from a 25℃ water bath until the center temperature reaches 10℃, absorb the surface moisture with absorbent paper, and then put it in 100℃ water for high and low temperature Cooking, strictly control the cooking temperature, take it out when the center temperature reaches 50°C, put it into a vacuum packaging bag, and finally cool it quickly in ice water to get pre-cooked beef;

[0033] (2) Secondary precooking (setting): add precooked beef into boiling water and boil for 20 minutes, add fresh ginger with 1-2% of the precooked beef weight to remove peculiar smell; remove and cool naturally, and filter the soup for later use;

[0034] (3) Slicing: Cut the second precooked beef into 0.5cm thin slices, requiring neat slice shape...

Embodiment 3

[0039] The present embodiment adjusts the production method of prefabricated beef products for secondary processing into beef jerky products, and the steps are as follows:

[0040] A process for secondary processing of pre-conditioned beef into beef jerky products, comprising the following steps:

[0041] (1) Pre-cooked beef: Divide fresh beef into 6cm×6cm×6cm pieces; take it out in a 15℃ water bath until the center temperature reaches 10℃, absorb the surface moisture with absorbent paper, and then put it in 95℃ water for high and low temperature Cooking, strictly control the cooking temperature, take it out when the central temperature reaches 45°C, put it into a vacuum packaging bag, and finally cool it quickly in ice water to get pre-cooked beef;

[0042] (2) Secondary precooking (setting): add the precooked beef into boiling water and cook for 20 minutes, add fresh ginger with 1.5% of the weight of the precooked beef to remove peculiar smell; remove and cool naturally, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com