Device for removing iron impurities from fine powder rare earth material

A fine powder and material technology, which is applied in the field of rare earth iron impurities removal equipment for fine powder materials, can solve the problems of sore arms of workers and the inability to clean and effectively remove iron impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

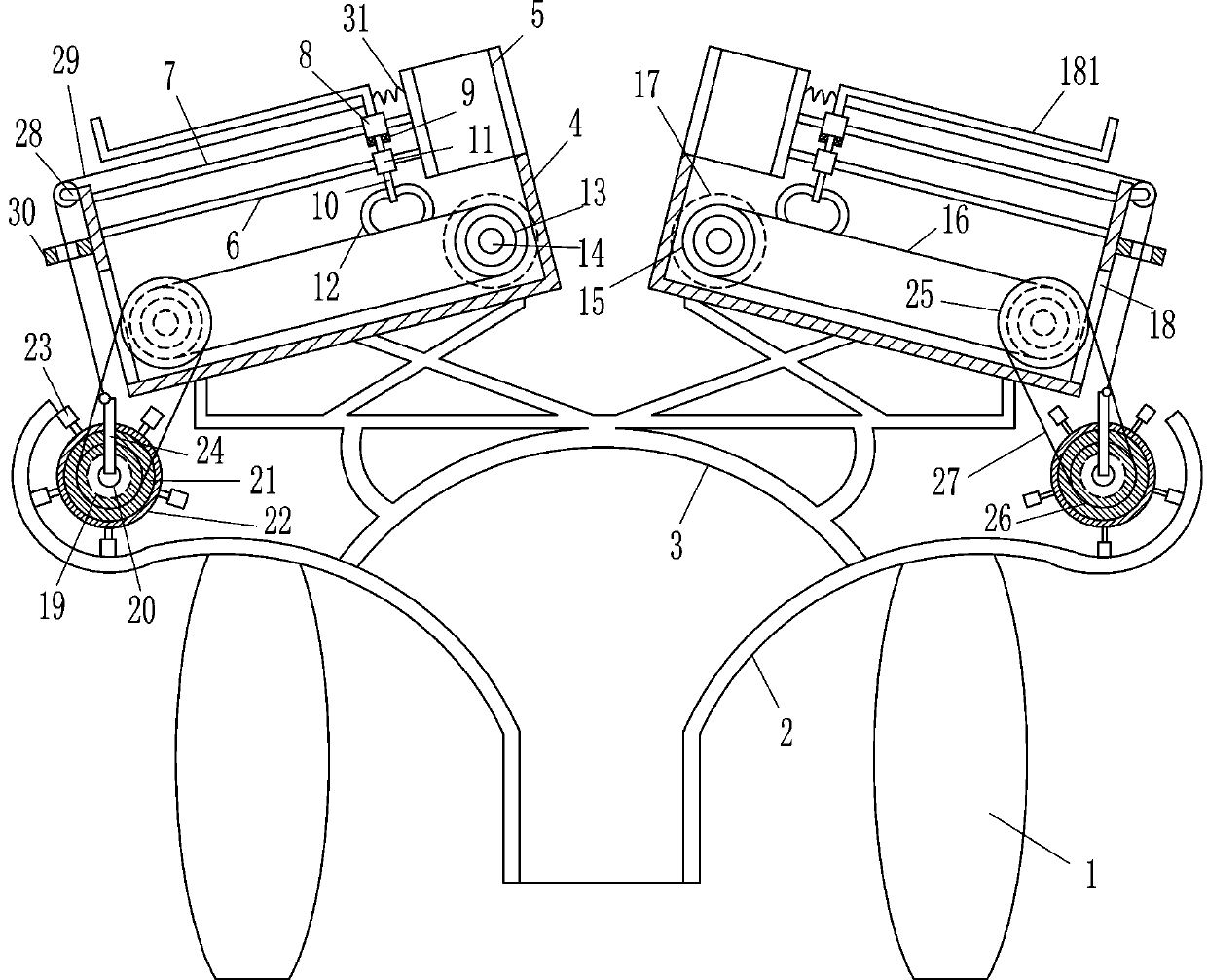

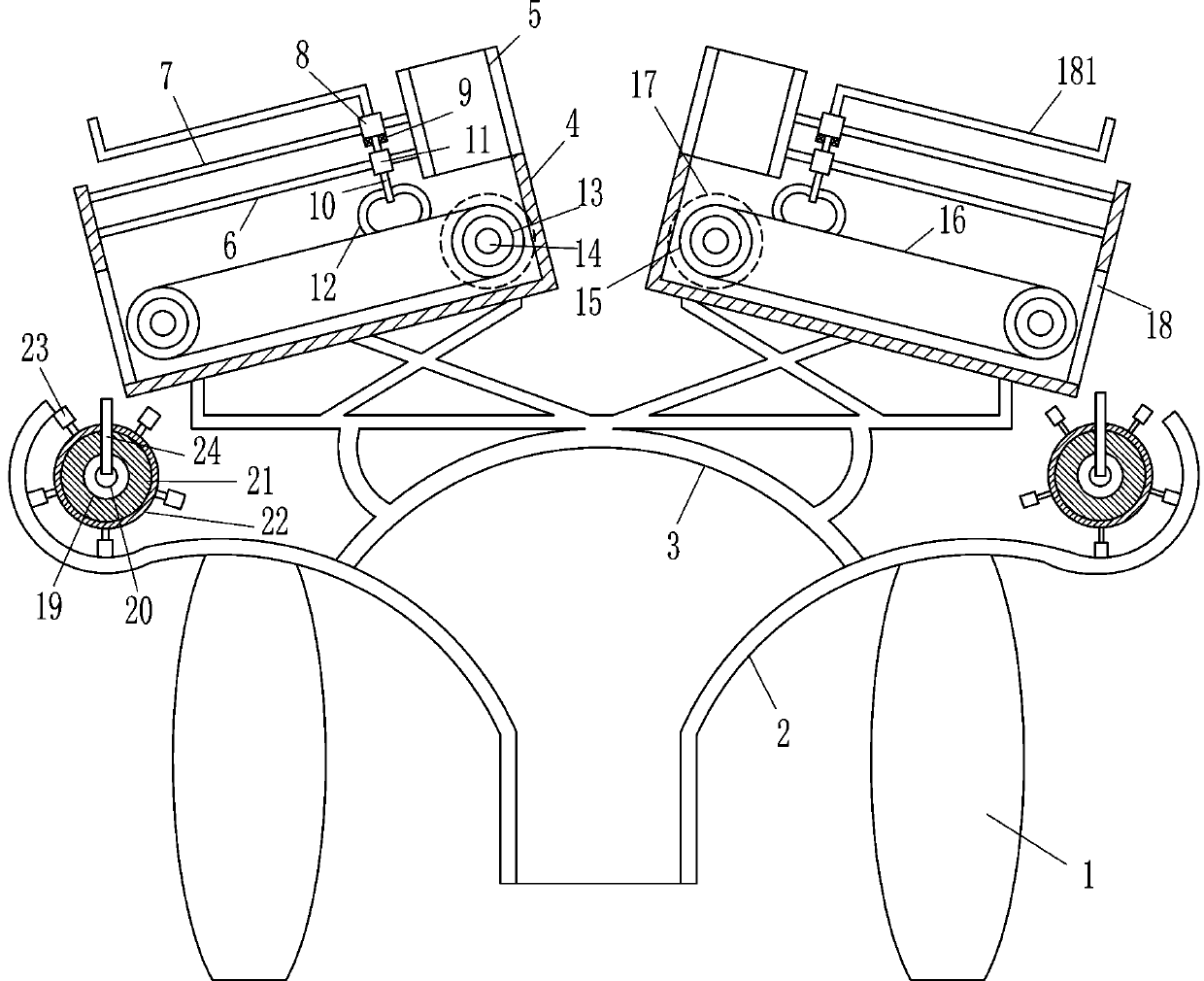

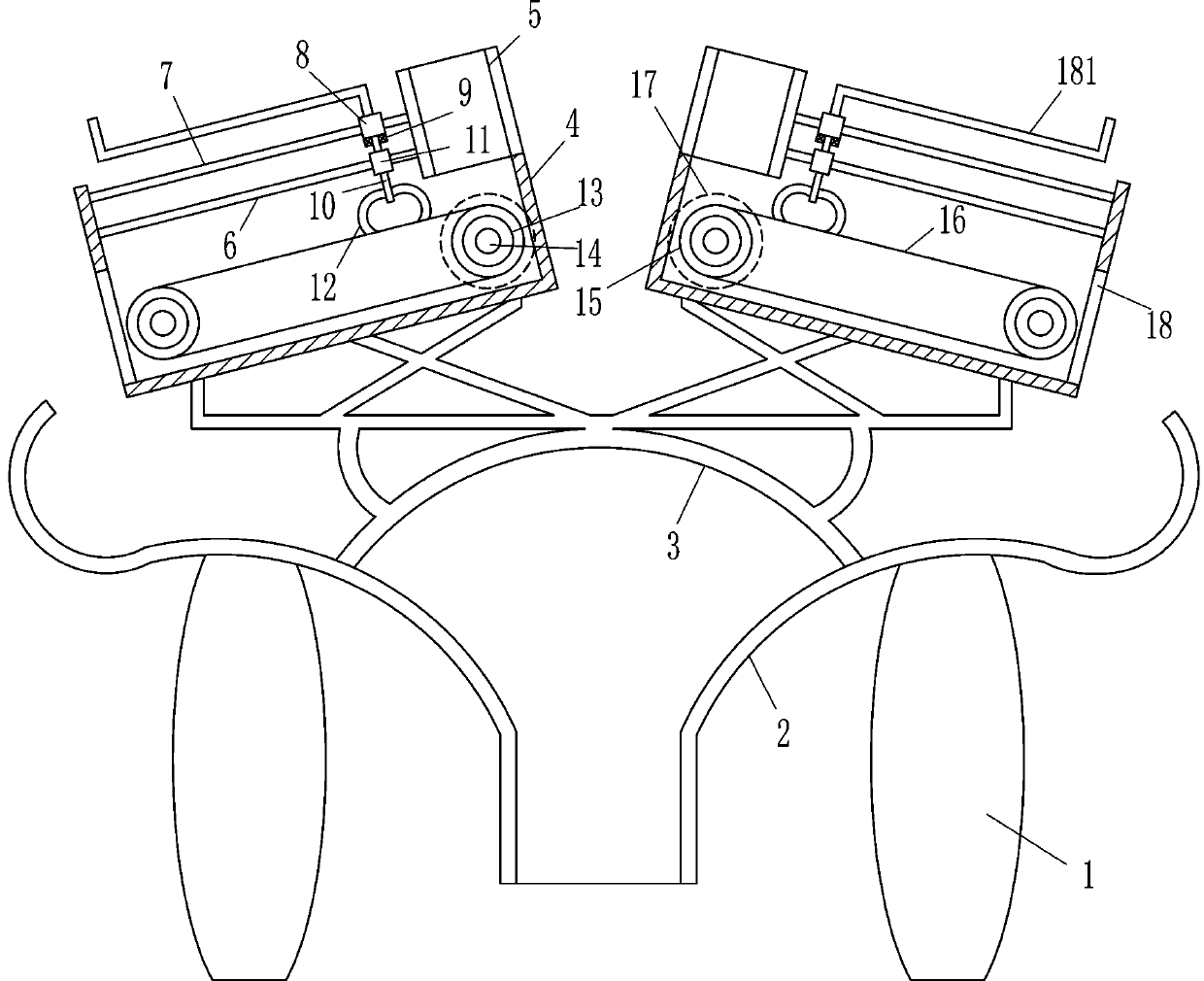

[0023] A device for removing iron impurities from rare earth fine powder materials, such as Figure 1-5 As shown, it includes a mounting column 1, a discharge box 2, a support frame 3, a sorting box 4, a feeding box 5, a rack 6, a guide rail 7, a first guide sleeve 8, a first bearing seat 9, and a first rotation The rod 10, the gear 11, the arc-shaped magnetic plate 12, the second bearing seat 13, the second rotating rod 14, the transmission wheel 15, the conveyor belt 16, the motor 17 and the pull rod 181. A discharge box 2 is provided between the top of the mounting column 1, There are support frames 3 between the upper parts of the left and right sides in the discharge box 2, and the top and left sides of the support frame 3 are equipped with sorting boxes 4, and the upper and lower inner sides of the inner walls of the sorting boxes 4 on the left and right sides are equipped with feed Box 5, the lower part of the outer side of the feed box 5 on the left and right sides are ...

Embodiment 2

[0025] A device for removing iron impurities from rare earth fine powder materials, such as Figure 1-5 As shown, it includes a mounting column 1, a discharge box 2, a support frame 3, a sorting box 4, a feeding box 5, a rack 6, a guide rail 7, a first guide sleeve 8, a first bearing seat 9, and a first rotation The rod 10, the gear 11, the arc-shaped magnetic plate 12, the second bearing seat 13, the second rotating rod 14, the transmission wheel 15, the conveyor belt 16, the motor 17 and the pull rod 181. A discharge box 2 is provided between the top of the mounting column 1, There are support frames 3 between the upper parts of the left and right sides in the discharge box 2, and the top and left sides of the support frame 3 are equipped with sorting boxes 4, and the upper and lower inner sides of the inner walls of the sorting boxes 4 on the left and right sides are equipped with feed Box 5, the lower part of the outer side of the feed box 5 on the left and right sides are ...

Embodiment 3

[0028] A device for removing iron impurities from rare earth fine powder materials, such as Figure 1-5 As shown, it includes a mounting column 1, a discharge box 2, a support frame 3, a sorting box 4, a feeding box 5, a rack 6, a guide rail 7, a first guide sleeve 8, a first bearing seat 9, and a first rotation The rod 10, the gear 11, the arc-shaped magnetic plate 12, the second bearing seat 13, the second rotating rod 14, the transmission wheel 15, the conveyor belt 16, the motor 17 and the pull rod 181. A discharge box 2 is provided between the top of the mounting column 1, There are support frames 3 between the upper parts of the left and right sides in the discharge box 2, and the top and left sides of the support frame 3 are equipped with sorting boxes 4, and the upper and lower inner sides of the inner walls of the sorting boxes 4 on the left and right sides are equipped with feed Box 5, the lower part of the outer side of the feed box 5 on the left and right sides are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com