Platepaint spraying device for buildings

A technology for construction and boards, which is applied in the field of board processing, can solve the problems of high work intensity, low painting efficiency, and inability to realize double-sided painting, and achieve the effect of preventing paint waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

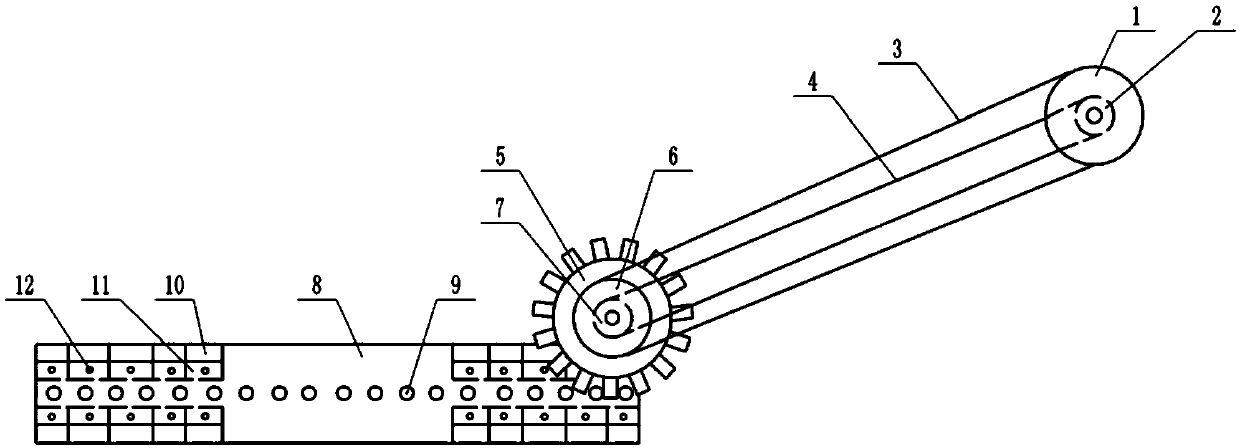

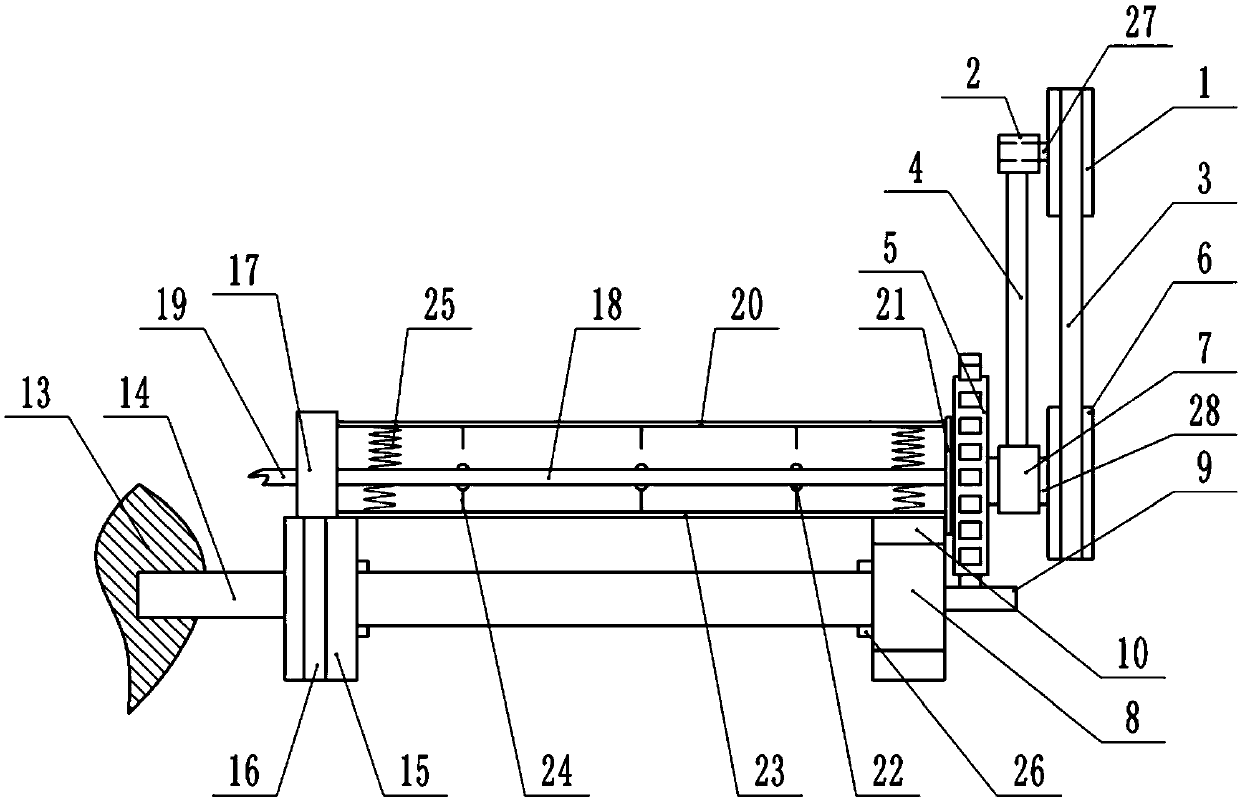

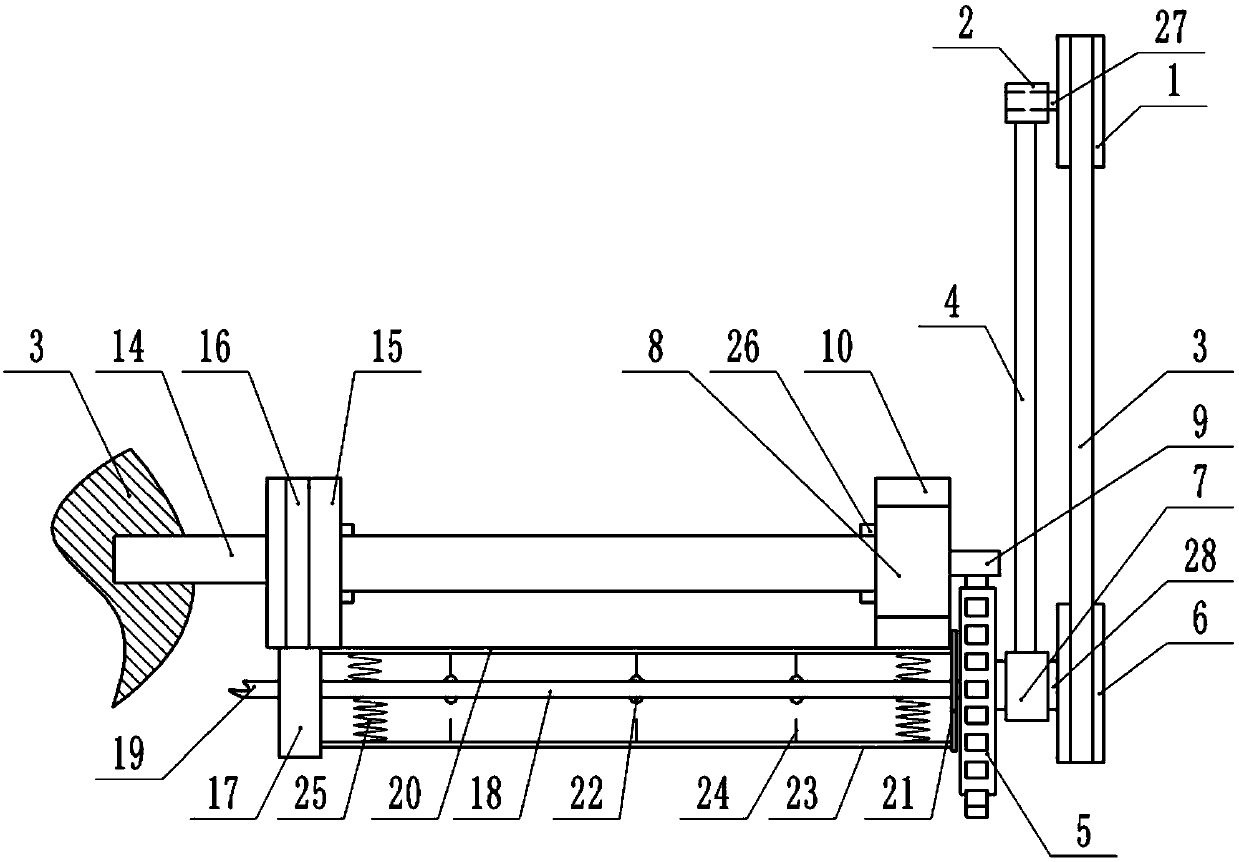

[0026] Embodiment 1 is basically as attached Figure 1-Figure 4 shown.

[0027] like figure 1 and figure 2As shown, the plate painting device for construction includes a frame, an active plate 8 and a driven plate 15 that are vertically arranged, the active plate 8 and the driven plate 15 are arranged oppositely, and the driven plate 15 is positioned at the rear of the active plate 8 . The top and the bottom of the active plate 8 are all provided with some movable blocks 10, the top and the bottom of the active plate 8 are all provided with some grooves 11, the movable blocks 10 are sealed and slidably connected in the groove 11, and the active plate 8 is provided with some The air inlet 12 communicated with the groove 11 is provided with an air valve, which can control whether the movable block 10 stretches out from the groove 11 by controlling whether to feed gas into the groove 11. A connecting plate is connected between the right end of the active plate 8 and the righ...

Embodiment 2

[0037] The difference between Embodiment 2 and Embodiment 1 lies in that the driving mechanism in Embodiment 2 is different from that in Embodiment 1. Embodiment 2 does not contain the first pulley 1, the second pulley 6 and the belt 3 in Embodiment 1. The driving mechanism in the second embodiment includes a motor slot arranged on the frame, and a motor is slidably connected in the motor slot, and the output shaft of the motor is directly coaxially connected with the gear 5 . The motor directly drives the gear 5 to rotate like this, and when the gear 5 swings, the motor slides in the motor groove following the swing of the gear 5, thereby adapting to the swing of the gear 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com