A Large Deformation Rubber Bearing with Limiting Combination Section of Cable and Reduced Shear Stiffness

A technology of rubber bearings and composite sections, which is applied in bridge engineering and anti-seismic fields. It can solve problems such as bridge rigidity that cannot meet traffic requirements, large lead rubber bearing displacement, and out-of-control displacement of anchor bolts, etc., to reduce costs and design and construction difficulties. , structural period extension, and the effect of reducing seismic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

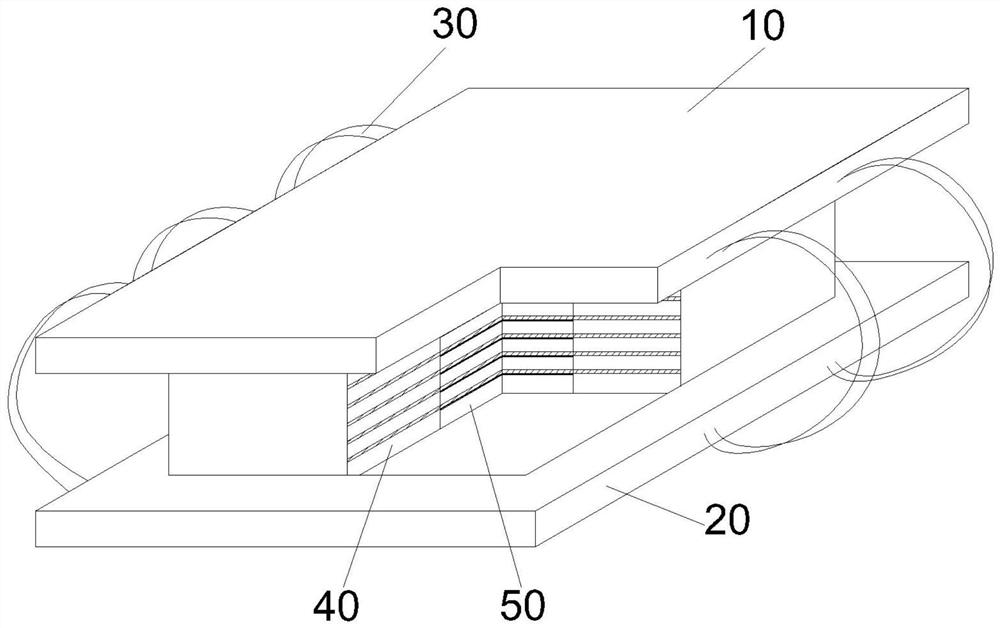

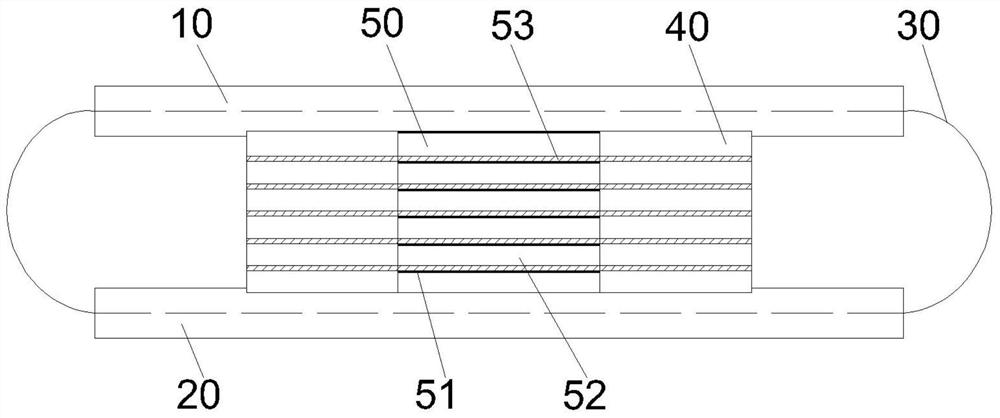

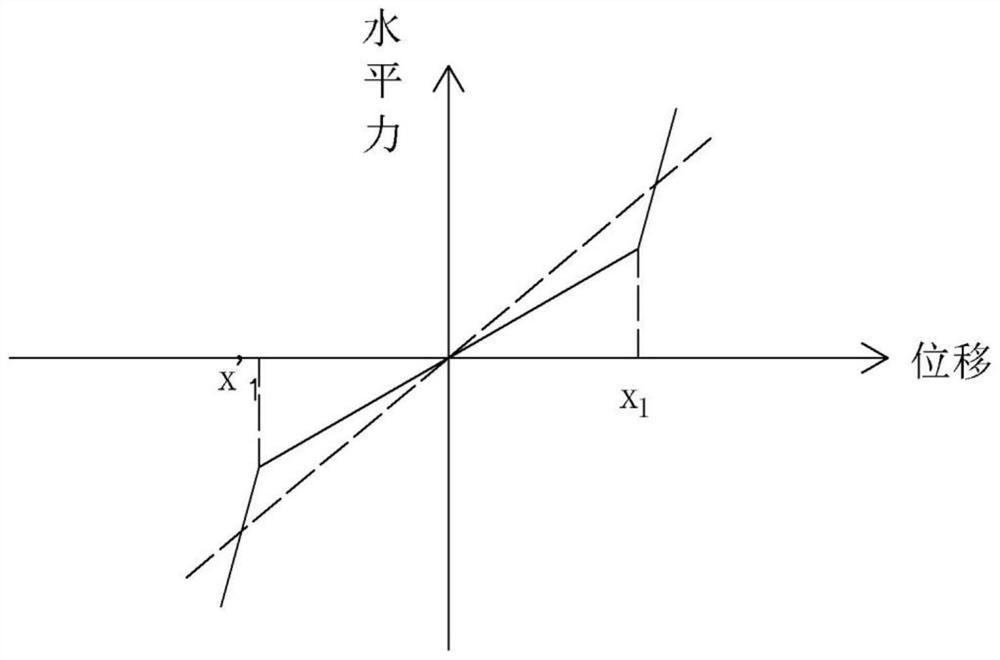

[0030] see Figure 1 ~ Figure 4 According to the present invention, a large-deformation rubber support with a limit combination section of a cable to reduce the shear stiffness includes an upper top plate 10, a lower top plate 20, a rubber support and a drag cable 30, and the rubber support is arranged on the upper top plate 10 and between the lower top plate 20. A plurality of first through holes 11 are opened on the upper top plate 10 along its horizontal direction, and a plurality of second through holes are opened on the lower top plate 20 along its horizontal direction. The cable 30 is passed through the first through hole 11 and the second through hole, and the two ends of the cable 30 are connected to form a closed structure. Each bundle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com