Rear guide rail beam

A technology of guide rail beams and rear guide rails, applied in the field of intelligent parking, to achieve the effects of easy popularization, firm structure, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

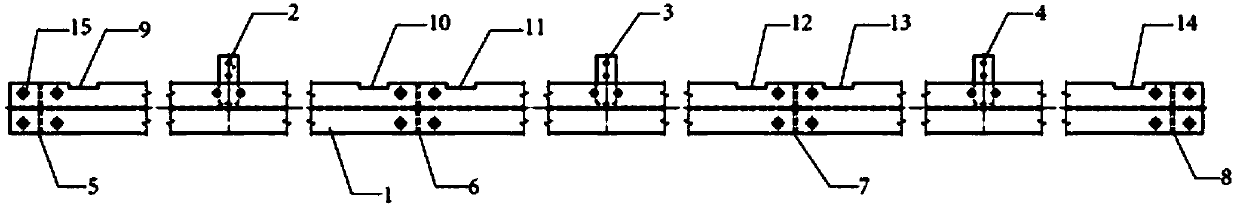

[0015] The distance between the first upper limit fixed plate and the second upper limit fixed plate is 2.45M, the distance between the second upper limit position fixed plate and the third upper limit fixed plate is 2.45M, and the guide rail beam is provided with six groove, the width of the groove is 0.06M, the distance between the first groove and the second groove is 2.208M, the distance between the second groove and the third groove is 0.172M, the third groove The distance between the fourth groove and the fourth groove is 2.208M, the distance between the fourth groove and the fifth groove is 0.172M, the distance between the fifth groove and the sixth groove is 2.208M, the guide rail beam The total length is 7.625M. There are 4 holes at both ends of the guide rail beam. The distance between the two ends of the guide rail beam is 0.0655M. The first rib and the fourth rib are respectively provided. The first rib and the second rib The distance between the second rib and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com