Resistance strain gauge pasting device

A technology of resistance strain gauges and strain gauges, which is applied in the direction of instruments, measuring devices, and material gluing, can solve the problems of strain gauge displacement, low efficiency, and poor working environment, and achieve the effect of improving efficiency and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the embodiments of the present invention are not limited thereto, and the scope of protection of the present invention also relates to those skilled in the art who can achieve according to the concept of the present invention. Think of the equivalent technical means.

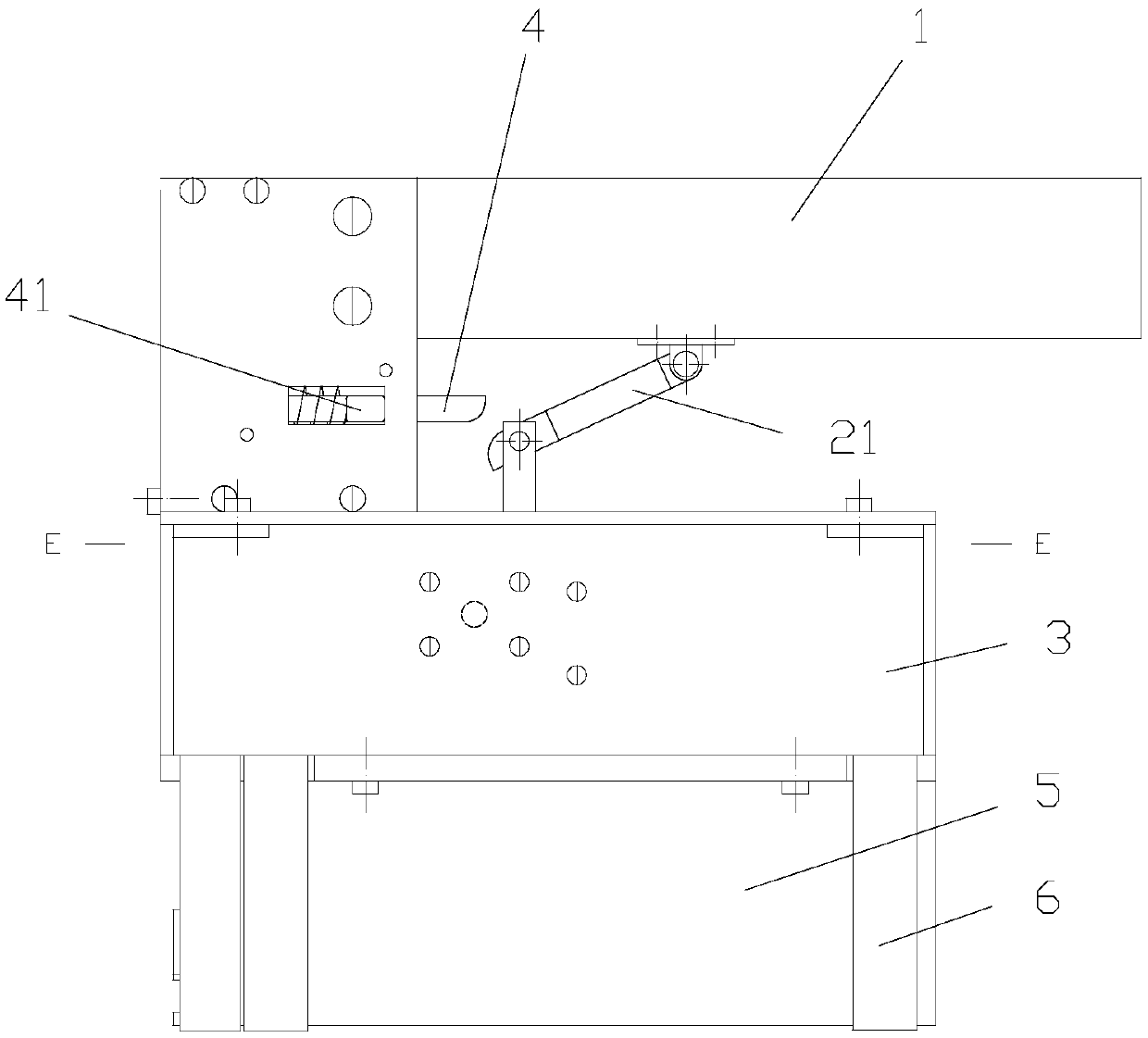

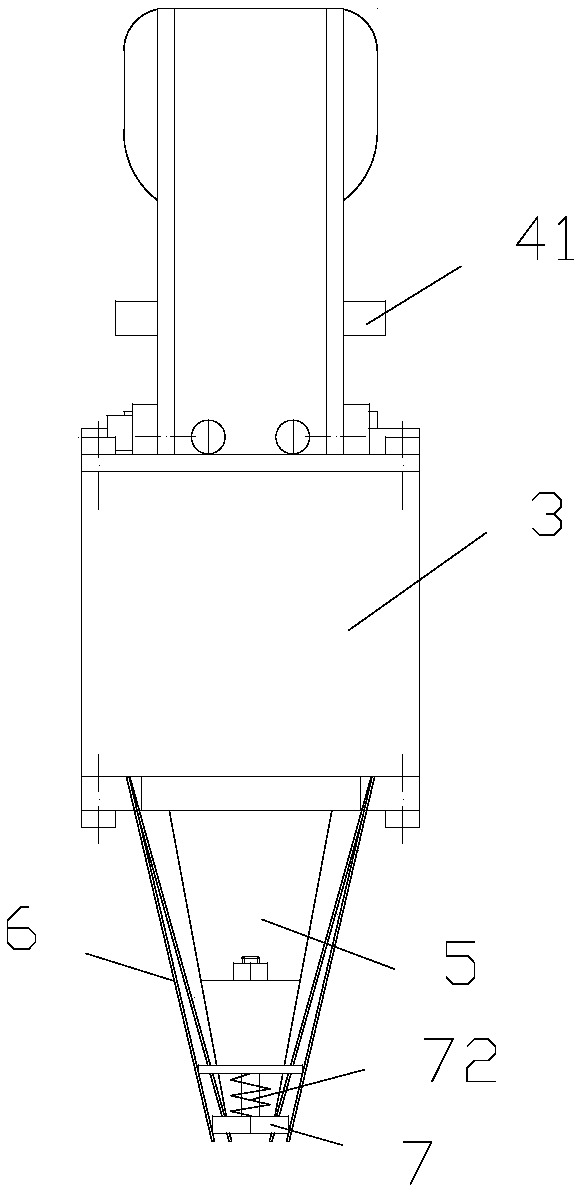

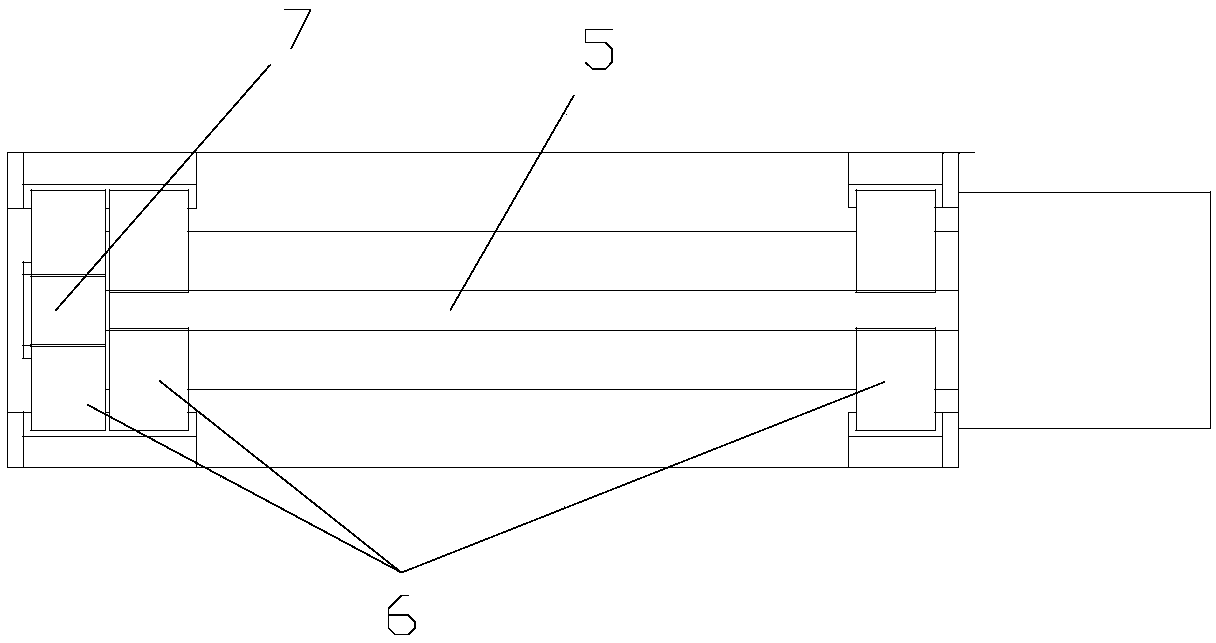

[0024] Such as Figures 1 to 6 As shown, a resistance strain gauge sticking device includes an inverted trapezoidal indenter 5, the end of the indenter 5 is provided with a scale that is convenient for aligning with the midline when the strain gauge is pasted, and the bottom surface of the indenter 5 is in line with the A plane matching the size of the strain gauge to be pasted, the indenter 5 cuts off a part of the upper and lower parts corresponding to the connection terminal of the strain gauge to be pasted, thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com