Oil well pipe special buckle screwing quality judgment method based on ensemble learning algorithm

An integrated learning and judgment method technology, applied in the field of data processing, can solve problems such as costing a lot of manpower and time, affecting the accuracy of judgment, and high quality risk, so as to improve the accuracy rate, increase the qualified rate of appearance, and avoid the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creation features, goals and effects realized by the present invention easy to understand, the method for judging the quality of the oil well pipe special screw connection based on the integrated learning algorithm of the present invention is described in detail below with reference to the embodiments and the accompanying drawings.

[0023]

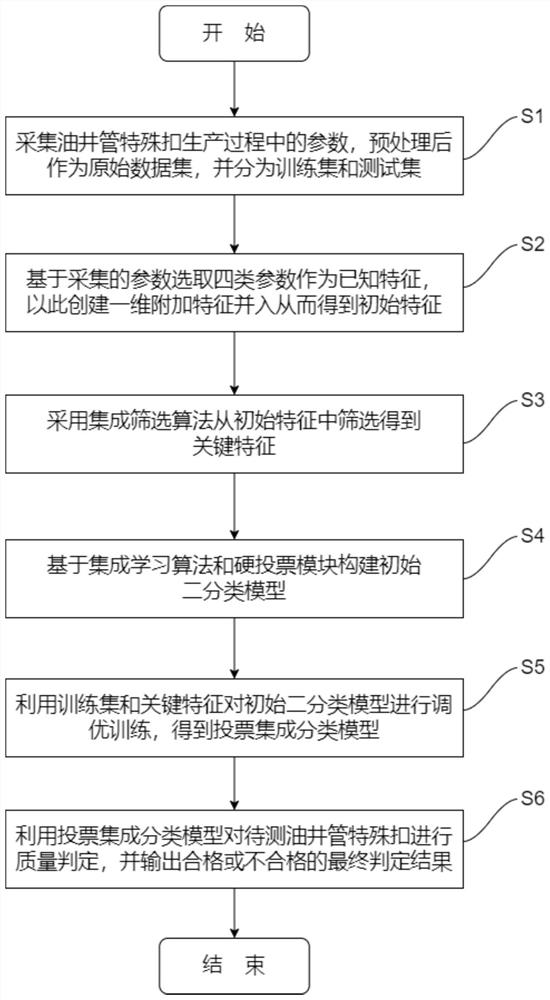

[0024] figure 1 It is a flow chart of the method for judging the quality of the special screw connection of oil well pipes based on the integrated learning algorithm in the embodiment of the present invention;

[0025] like figure 1 As shown in the figure, the method for determining the quality of oil well pipe special snaps and connections based on the integrated learning algorithm includes some steps:

[0026] In step S1, the parameters in the production process of the special buckle of the oil well pipe are collected, used as the original data set after preprocessing, and the original dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com