Load Adaptive Combined Heating System and Heating Method

A heating system and self-adaptive technology, applied in the energy field, can solve problems such as the inability of heat source equipment to coordinate heating, and achieve the effects of improving energy utilization, reducing renovation costs, and reducing wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings.

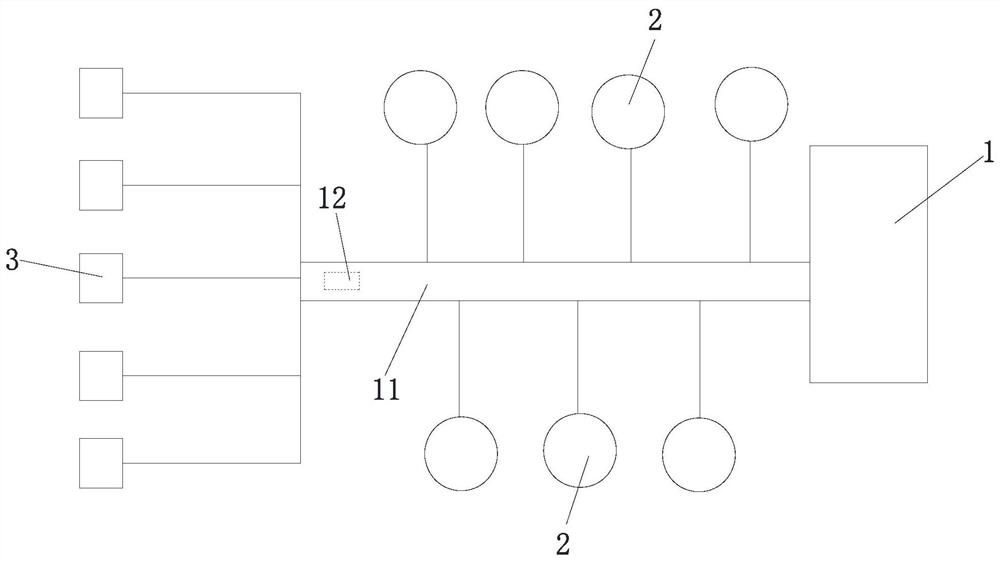

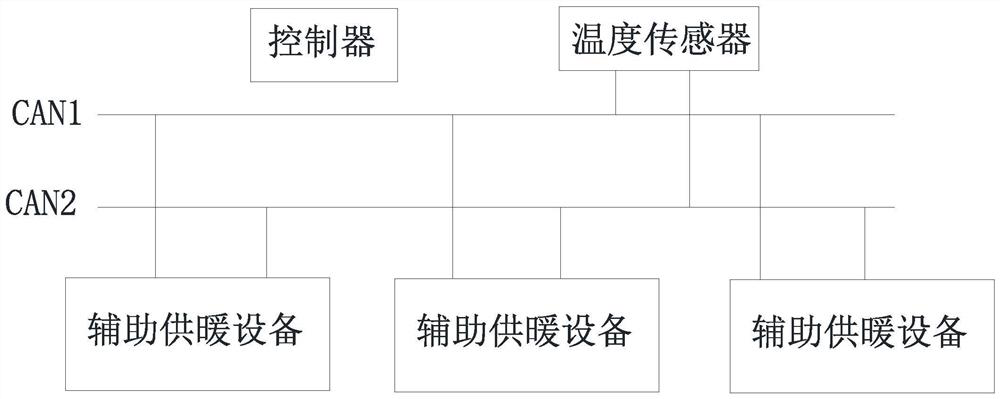

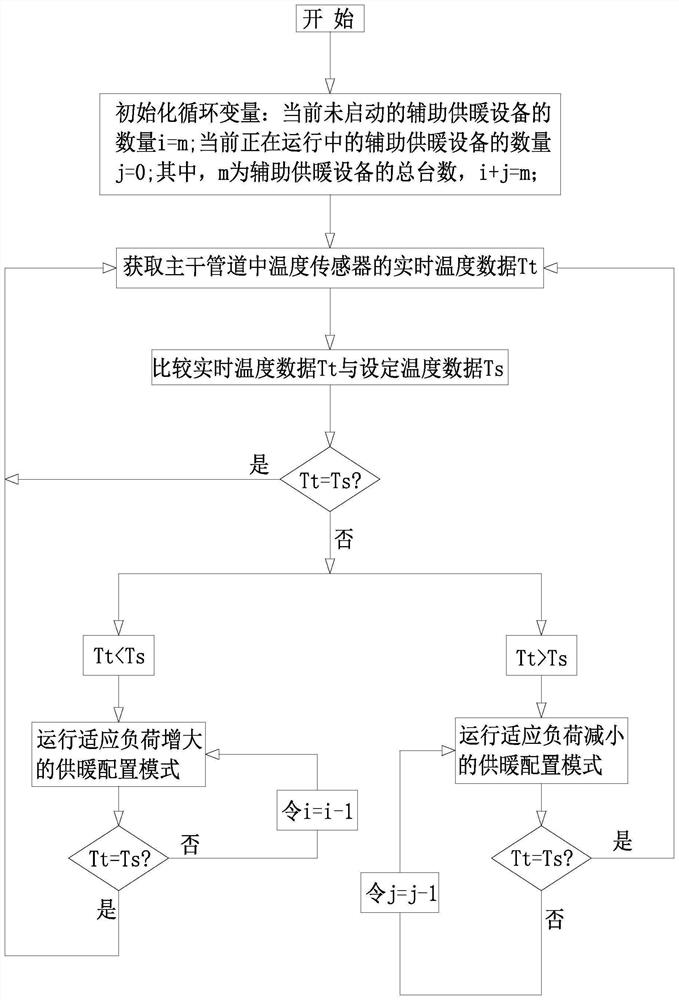

[0050] see figure 1 and figure 2 , a load adaptive combined heating system, including a controller, main heating equipment 1 and several auxiliary heating equipment 2; the thermal energy output pipe of the main heating equipment 1 is used as a main pipeline 11 for outputting heat energy to each heating user 3; The heat energy output pipes of each auxiliary heating equipment 2 are respectively connected to the main pipeline 11 as sub-trunk pipelines, so that heat energy can be collected in the main pipeline 11; it also includes a temperature sensor set in the main pipeline 11 for real-time collection of the temperature of the heat transfer medium. Sensor 12, the temperature sensor 12 is arranged in the main pipe 11 near the end of the heating user, so that it can sense the temperature change caused by the load change of the user end in time, so as to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com